A conveyor belt is the carrying medium of a belt conveyor system. A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys, with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more.

The Archimedes screw, also known as the Archimedean screw, hydrodynamic screw, water screw or Egyptian screw, is one of the earliest hydraulic machines. Using Archimedes screws as water pumps dates back many centuries. As a machine used for transferring water from a low-lying body of water into irrigation ditches, water is pumped by turning a screw-shaped surface inside a pipe. In the modern world, Archimedes screw pumps are widely used in wastewater treatment plants and for dewatering low-lying regions. Archimedes Screws Turbines (ASTs) are a new form of small hydroelectric powerplant that can be applied even in low head sites. Archimedes screw generators operate in a wide range of flows and heads, including low heads and moderate flow rates that is not ideal for traditional turbines and not occupied by high performance technologies. The Archimedes screw is a reversible hydraulic machine, and there are several examples of Archimedes screw installations where the screw can operate at different times as either pump or generator, depending on needs for power and watercourse flow.

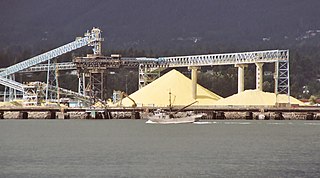

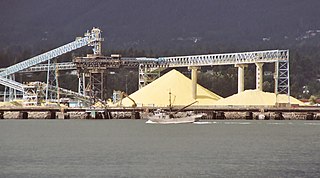

Bulk material handling is an engineering field that is centered on the design of equipment used for the handling of dry materials. Bulk materials are those dry materials which are powdery, granular or lumpy in nature, and are stored in heaps. Examples of bulk materials are minerals, ores, coal, cereals, woodchips, sand, gravel, clay, cement, ash, salt, chemicals, grain, sugar, flour and stone in loose bulk form. It can also relate to the handling of mixed wastes. Bulk material handling is an essential part of all industries that process bulk ingredients, including: food, beverage, confectionery, pet food, animal feed, tobacco, chemical, agricultural, polymer, plastic, rubber, ceramic, electronics, metals, minerals, paint, paper, textiles and more.

A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

A beltweigher or belt weigher is a piece of industrial control equipment used to gauge the mass or flow rate of material travelling over a troughed (cupped) conveyor belt of any length which is able to adequately contain the material being weighed. These are also known as belt scales, dynamic scales, conveyor scales, and in-motion weighers. Many such check weighers or feed weighers are an active part of the process flow control of the conveyor line.

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat, and bone meal, municipal solid waste, and many others. The first type of screw conveyor was the Archimedes' screw, used since ancient times to pump irrigation water.

Rotary feeders, also known as rotary airlocks or rotary valves, are commonly used in industrial and agricultural applications as a component in a bulk or specialty material handling system. Rotary feeders are primarily used for discharge of bulk solid material from hoppers/bins, receivers, and cyclones into a pressure or vacuum-driven pneumatic conveying system. Components of a rotary feeder include a rotor shaft, housing, head plates, and packing seals and bearings. Rotors have large vanes cast or welded on and are typically driven by small internal combustion engines or electric motors.

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

A concrete plant, also known as a batch plant or batching plant or a concrete batching plant, is equipment that combines various ingredients to form concrete. Some of these inputs include water, air, admixtures, sand, aggregate, fly ash, silica fume, slag, and cement. A concrete plant can have a variety of parts and accessories, including: mixers, cement batchers, aggregate batchers, conveyors, radial stackers, aggregate bins, cement bins, heaters, chillers, cement silos, batch plant controls, and dust collectors.

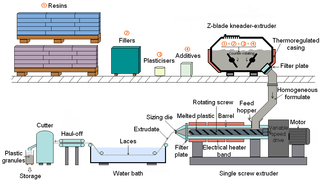

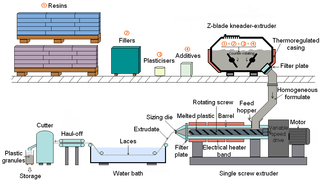

Compounding consists of preparing plastic formulations by mixing and/or blending polymers and additives in a molten state to achieve the desired characteristics. These blends are automatically dosed with fixed setpoints usually through feeders/hoppers. It is mostly a blend of copolymers such as ABS, SAN, SMA etc. with additives such as anti-oxidants, UV-stabilizers and other value adding agents and sometimes a strengthening component is added such as glass fibre.

Vibratory bowl feeders, also known as a bowl feeders, are common devices used to orient and feed individual component parts for assembly on industrial production lines. They are used when a randomly sorted bulk package of small components must be fed into another machine one-by-one, oriented in a particular direction.

A Vision Guided Robot (VGR) System is basically a robot fitted with one or more cameras used as sensors to provide a secondary feedback signal to the robot controller to more accurately move to a variable target position. VGR is rapidly transforming production processes by enabling robots to be highly adaptable and more easily implemented, while dramatically reducing the cost and complexity of fixed tooling previously associated with the design and set up of robotic cells, whether for material handling, automated assembly, agricultural applications, life sciences, and more.

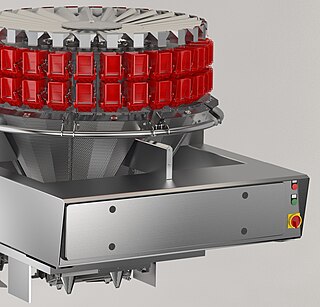

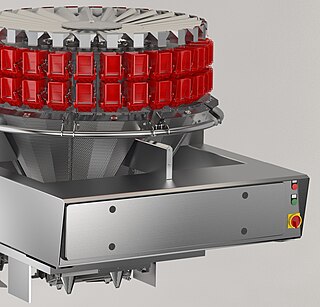

A multihead weigher is a fast, accurate and reliable weighing machine, used in packing both food and non-food products.

Pharmaceutical manufacturing is the process of industrial-scale synthesis of pharmaceutical drugs as part of the pharmaceutical industry. The process of drug manufacturing can be broken down into a series of unit operations, such as milling, granulation, coating, tablet pressing, and others.

Fillers are used for packaging, mainly for food/beverage but for other products as well. These are used to fill either a bottle or a pouch, depending on the product.

RNA Automation, a member of Rhein-Nadel Automation, was established in Birmingham UK in 1986, and has progressed into becoming the major supplier of parts handling equipment in the UK. The company operates in the area of specialised Automation engineering, providing automatic parts handling equipment for high volume production in the cosmetics, pharmaceutical, electronics, food and metal working industries, with seven manufacturing facilities across Europe and North America and a network of sales and service outlets across the globe.

Screen/Scroll centrifuge is a filtering or screen centrifuge which is also known as worm screen or conveyor discharge centrifuge. This centrifuge was first introduced in the midst of 19th century. After developing new technologies over the decades, it is now one of the widely used processes in many industries for the separation of crystalline, granular or fibrous materials from a solid-liquid mixture. Also, this process is considered to dry the solid material. This process has been some of the most frequently seen within, especially, coal preparation industry. Moreover, it can be found in other industries such as chemical, environmental, food and other mining fields.

A stabilized soil mixing plant is a combination of kinds of machines used for mixing stabilized soil, which is used for highway construction, municipal road projects, and fertile airport areas. The plant produces stabilized soil with different gradings in a continuous way. Such a plant usually contains a cement silo, measuring and conveying system, and mixing devices.

Pasta processing is the process in which wheat semolina or flour is mixed with water and the dough is extruded to a specific shape, dried and packaged.

NIAflow is simulation software for mineral processing plants. Based on a flowsheet interface, it calculates the material flow through a variety of processing machinery.