An aircraft is a vehicle that is able to fly by gaining support from the air. It counters the force of gravity by using either static lift or the dynamic lift of an airfoil, or, in a few cases, direct downward thrust from its engines. Common examples of aircraft include airplanes, helicopters, airships, gliders, paramotors, and hot air balloons.

Monocoque, also called structural skin, is a structural system in which loads are supported by an object's external skin, in a manner similar to an egg shell. The word monocoque is a French term for "single shell".

The fuselage is an aircraft's main body section. It holds crew, passengers, or cargo. In single-engine aircraft, it will usually contain an engine as well, although in some amphibious aircraft the single engine is mounted on a pylon attached to the fuselage, which in turn is used as a floating hull. The fuselage also serves to position the control and stabilization surfaces in specific relationships to lifting surfaces, which is required for aircraft stability and maneuverability.

A jet airliner or jetliner is an airliner powered by jet engines. Airliners usually have two or four jet engines; three-engined designs were popular in the 1970s but are less common today. Airliners are commonly classified as either the large wide-body aircraft, medium narrow-body aircraft and smaller regional jet.

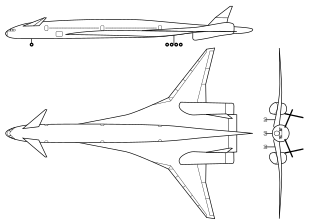

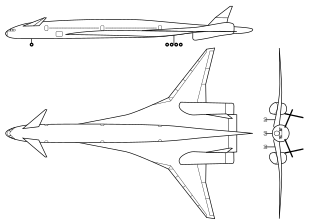

The Boeing Sonic Cruiser was a concept jet airliner with a delta wing–canard configuration. It was distinguished from conventional airliners by its delta wing and high-subsonic cruising speed of up to Mach 0.98. Boeing first proposed it in 2001, but airlines generally preferred lower operating costs over higher speed. Boeing ended the Sonic Cruiser project in December 2002 and shifted to the slower, but more fuel-efficient 7E7 airliner.

Glare is a fiber metal laminate (FML) composed of several very thin layers of metal interspersed with layers of S-2 glass-fiber pre-preg, bonded together with a matrix such as epoxy. The uni-directional pre-preg layers may be aligned in different directions to suit predicted stress conditions.

An airplane, or aeroplane, informally plane, is a fixed-wing aircraft that is propelled forward by thrust from a jet engine, propeller, or rocket engine. Airplanes come in a variety of sizes, shapes, and wing configurations. The broad spectrum of uses for airplanes includes recreation, transportation of goods and people, military, and research. Worldwide, commercial aviation transports more than four billion passengers annually on airliners and transports more than 200 billion tonne-kilometers of cargo annually, which is less than 1% of the world's cargo movement. Most airplanes are flown by a pilot on board the aircraft, but some are designed to be remotely or computer-controlled such as drones.

Cabin pressurization is a process in which conditioned air is pumped into the cabin of an aircraft or spacecraft in order to create a safe and comfortable environment for passengers and crew flying at high altitudes. For aircraft, this air is usually bled off from the gas turbine engines at the compressor stage, and for spacecraft, it is carried in high-pressure, often cryogenic, tanks. The air is cooled, humidified, and mixed with recirculated air if necessary before it is distributed to the cabin by one or more environmental control systems. The cabin pressure is regulated by the outflow valve.

A blended wing body (BWB), also known as blended body, hybrid wing body (HWB) or a lifting aerofoil fuselage, is a fixed-wing aircraft having no clear dividing line between the wings and the main body of the craft. The aircraft has distinct wing and body structures, which are smoothly blended together with no clear dividing line. This contrasts with a flying wing, which has no distinct fuselage, and a lifting body, which has no distinct wings. A BWB design may or may not be tailless.

A twinjet or twin-engine jet is a jet aircraft powered by two engines. A twinjet is able to fly well enough to land with a single working engine, making it safer than a single-engine aircraft in the event of failure of an engine. Fuel efficiency of a twinjet is better than that of aircraft with more engines. These considerations have led to the widespread use of aircraft of all types with twin engines, including airliners, fixed-wing military aircraft, and others.

The Boeing XP-9 was the first monoplane fighter aircraft produced by the United States aircraft manufacturing company Boeing. It incorporated sophisticated structural refinements that were influential in later Boeing designs. The sole prototype exhibited unsatisfactory characteristics with its lack of pilot visibility directly leading to its cancellation.

In a fixed-wing aircraft, the spar is often the main structural member of the wing, running spanwise at right angles to the fuselage. The spar carries flight loads and the weight of the wings while on the ground. Other structural and forming members such as ribs may be attached to the spar or spars, with stressed skin construction also sharing the loads where it is used. There may be more than one spar in a wing or none at all. Where a single spar carries most of the force, it is known as the main spar.

The Junkers J 1, nicknamed the Blechesel, was an experimental monoplane aircraft developed by Junkers & Co. It was the world's first all-metal aircraft.

The Bristol M.R.1 was an experimental biplane with an aluminium monocoque fuselage and metal wings, produced by Bristol during the First World War. Two were built to government order.

Vincent A. Weldon is an American aerospace engineer who has designed critical components for both the Apollo moon mission and the Space Shuttle. Weldon attracted controversy in 2006 for his criticism of the Boeing 787 Dreamliner, an airliner he claims is unsafe, and for his sacking from Boeing shortly afterwards under disputed circumstances.

The aircraft design process is a loosely defined method used to balance many competing and demanding requirements to produce an aircraft that is strong, lightweight, economical and can carry an adequate payload while being sufficiently reliable to safely fly for the design life of the aircraft. Similar to, but more exacting than, the usual engineering design process, the technique is highly iterative, involving high level configuration tradeoffs, a mixture of analysis and testing and the detailed examination of the adequacy of every part of the structure. For some types of aircraft, the design process is regulated by civil airworthiness authorities.

The fuel economy in aircraft is the measure of the transport energy efficiency of aircraft. Efficiency is increased with better aerodynamics and by reducing weight, and with improved engine BSFC and propulsive efficiency or TSFC. Endurance and range can be maximized with the optimum airspeed, and economy is better at optimum altitudes, usually higher. An airline efficiency depends on its fleet fuel burn, seating density, air cargo and passenger load factor, while operational procedures like maintenance and routing can save fuel.

The British Aerospace (BAe) P.1216 was a planned Advanced Short Take Off/Vertical Landing (ASTOVL) supersonic aircraft from the 1980s. It was designed by the former Hawker design team at Kingston upon Thames, Surrey, England that created the Harrier family of aircraft.

The period between 1945 and 1979 is sometimes called the post-war era or the period of the post-war political consensus. During this period, aviation was dominated by the arrival of the Jet Age. In civil aviation the jet engine allowed a huge expansion of commercial air travel, while in military aviation it led to the widespread introduction of supersonic aircraft.

Aircraft recycling is the process of scrapping and disassembling retired aircraft, and re-purposing their parts as spare parts or scrap. Airplanes are made of around 800 to 1000 parts that can be recycled, with the majority of them made from metal alloys and composite materials. The two most common metal alloys are aluminum and titanium and the main composite material is carbon fiber.