A poppet valve is a valve typically used to control the timing and quantity of gas or vapor flow into an engine.

A flush toilet is a toilet that disposes of human waste by using the force of water to flush it through a drainpipe to another location for treatment, either nearby or at a communal facility, thus maintaining a separation between humans and their waste. Flush toilets can be designed for sitting or for squatting, in the case of squat toilets. Most modern sewage treatment systems are also designed to process specially designed toilet paper. The opposite of a flush toilet is a dry toilet, which uses no water for flushing.

The vacuum brake is a braking system employed on trains and introduced in the mid-1860s. A variant, the automatic vacuum brake system, became almost universal in British train equipment and in countries influenced by British practice. Vacuum brakes also enjoyed a brief period of adoption in the United States, primarily on narrow-gauge railroads. Their limitations caused them to be progressively superseded by compressed air systems starting in the United Kingdom from the 1970s onward. The vacuum brake system is now obsolete; it is not in large-scale usage anywhere in the world, other than in South Africa, largely supplanted by air brakes.

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid to flow through it in only one direction.

A siphon is any of a wide variety of devices that involve the flow of liquids through tubes. In a narrower sense, the word refers particularly to a tube in an inverted "U" shape, which causes a liquid to flow upward, above the surface of a reservoir, with no pump, but powered by the fall of the liquid as it flows down the tube under the pull of gravity, then discharging at a level lower than the surface of the reservoir from which it came.

A backflow prevention device is used to protect potable water supplies from contamination or pollution due to backflow.

A double check valve or double check assembly (DCA) is a backflow prevention device designed to protect water supplies from contamination. It is different from the two-way check valves used in air brake systems on heavy trucks which select from the highest pressure source.

Sometimes called a check valve or a backflow preventer, a chemigation valve is an apparatus designed to protect water supplies from agricultural chemicals used during chemigation, the application of chemicals such as fertilizers and pesticides through irrigation water. Most chemigation valves consist of a spring-loaded check valve, a low pressure drain, an air and vacuum relief valve, and an injection port for introducing the chemicals downstream of the check valve. Many chemigation valves also have a 4-inch inspection port so that a person can reach inside and feel if the check valve is still functional. Some governments require the use of two chemigation valves installed in series if hazardous chemicals are to be injected.

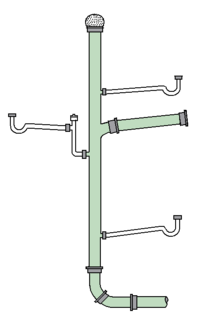

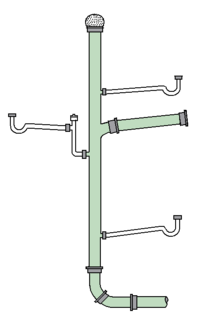

In modern plumbing, a drain-waste-vent is a system that allows air to enter the plumbing system to maintain proper air pressure to enable the removal of sewage and greywater from a dwelling. Drain refers to water produced at fixtures such as sinks, and showers; waste refers to water from toilets. As the water runs down, proper venting is required to allow water to flow freely, and avoid a vacuum from being created. As the water runs down air must be allowed into the waste pipe either through a roof vent (external), or an internal vent.

An atmospheric railway uses differential air pressure to provide power for propulsion of a railway vehicle. A static power source can transmit motive power to the vehicle in this way, avoiding the necessity of carrying mobile power generating equipment. The air pressure, or partial vacuum can be conveyed to the vehicle in a continuous pipe, where the vehicle carries a piston running in the tube. Some form of re-sealable slot is required to enable the piston to be attached to the vehicle. Alternatively the entire vehicle may act as the piston in a large tube or be coupled electromagnetically to the piston.

Hydronics is the use of liquid water or gaseous water (steam) or a water solution as heat-transfer medium in heating and cooling systems. The name differentiates such systems from oil and steam systems. Historically, in large-scale commercial buildings such as high-rise and campus facilities, a hydronic system may include both a chilled and a heated water loop, to provide for both heating and air conditioning. Chillers and cooling towers are used either separately or together as means to provide water cooling, while boilers heat water. A recent innovation is the chiller boiler system, which provides an efficient form of HVAC for homes and smaller commercial spaces.

An air gap, as related to the plumbing trade, is the unobstructed vertical space between the water outlet and the flood level of a fixture. Air gaps of appropriate design are required for water safety by legislation in many countries. A related term in computer security is network air gap.

A hydrostatic loop, though not often used in plumbing practice, is an arrangement of pipes formed into a vertical loop to prevent backflow of water within the plumbing potable water system. Since a siphon has a maximum height that it can work, a hydrostatic loop is built higher than 33 feet. There are several ways to prevent siphonage and an undesirable backflow of the water in a plumbing system.

A vacuum breaker is an attachment commonly placed on a bibcock valve or toilet or urinal flush valve, that prevents water from being siphoned backward into the public drinking water system. This prevents contamination should the public drinking water system's pressure drop.

A pressure vacuum breaker (PVB) is a type of backflow prevention device, used to keep non-potable water from entering the water supply. A PVB is similar to an atmospheric vacuum breaker (AVB), except that the PVB contains a spring-loaded poppet. This makes it acceptable for applications that are high hazard or where valves are downstream. Pressure vacuum breakers must be protected from freezing when installed outdoors. PVBs usually have test cocks, to which specially-calibrated gauges are attached, in order to ensure that they are functioning properly.

A reduced pressure zone device is a type of backflow prevention device used to protect water supplies from contamination. RPZDs may also be known as reduced pressure principle (RP), reduced pressure principle backflow prevention devices, reduced pressure zone assemblies (RPZA), or reduced pressure principle assembly (RPPA).

A throttle is the mechanism by which fluid flow is managed by constriction or obstruction.

A pressure regulator is a valve that controls the pressure of a fluid or gas to a desired value, using negative feedback from the controlled pressure. Regulators are used for gases and liquids, and can be an integral device with a pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and flow valve.

Chest drains are surgical drains placed within the pleural space to facilitate removal of unwanted substances in order to preserve respiratory functions and hemodynamic stability. Some chest drains may utilize a flutter valve to prevent retrograde flow, but those that do not have physical valves employ a water trap seal design, often aided by continuous suction from a wall suction or a portable vacuum pump.