Plumbing is any system that conveys fluids for a wide range of applications. Plumbing uses pipes, valves, plumbing fixtures, tanks, and other apparatuses to convey fluids. Heating and cooling (HVAC), waste removal, and potable water delivery are among the most common uses for plumbing, but it is not limited to these applications. The word derives from the Latin for lead, plumbum, as the first effective pipes used in the Roman era were lead pipes.

Tap water is water supplied through a tap, a water dispenser valve. In many countries, tap water usually has the quality of drinking water. Tap water is commonly used for drinking, cooking, washing, and toilet flushing. Indoor tap water is distributed through indoor plumbing, which has existed since antiquity but was available to very few people until the second half of the 19th century when it began to spread in popularity in what are now developed countries. Tap water became common in many regions during the 20th century, and is now lacking mainly among people in poverty, especially in developing countries.

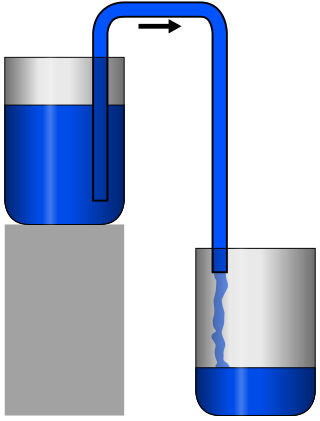

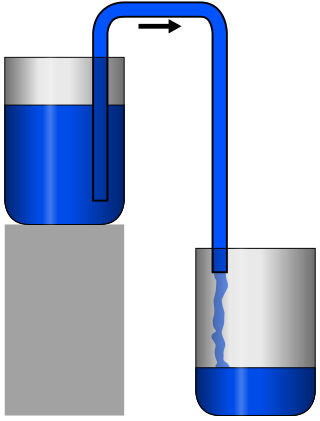

A siphon is any of a wide variety of devices that involve the flow of liquids through tubes. In a narrower sense, the word refers particularly to a tube in an inverted "U" shape, which causes a liquid to flow upward, above the surface of a reservoir, with no pump, but powered by the fall of the liquid as it flows down the tube under the pull of gravity, then discharging at a level lower than the surface of the reservoir from which it came.

A tap is a valve controlling the release of a fluid.

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses.

A plumbing fixture is an exchangeable device which can be connected to a plumbing system to deliver and drain water.

A backflow prevention device is used to protect potable water supplies from contamination or pollution due to backflow.

Sometimes called a check valve or a backflow preventer, a chemigation valve is an apparatus designed to protect water supplies from agricultural chemicals used during chemigation, the application of chemicals such as fertilizers and pesticides through irrigation water. Most chemigation valves consist of a spring-loaded check valve, a low pressure drain, an air and vacuum relief valve, and an injection port for introducing the chemicals downstream of the check valve. Many chemigation valves also have a 4-inch inspection port so that a person can reach inside and feel if the check valve is still functional. Some governments require the use of two chemigation valves installed in series if hazardous chemicals are to be injected.

In modern plumbing, a drain-waste-vent is a system that allows air to enter the plumbing system to maintain proper air pressure to enable the removal of sewage and greywater from a dwelling. Drain refers to water produced at fixtures such as sinks, and showers; waste refers to water from toilets. As the water runs down, proper venting is required to allow water to flow freely, and avoid a vacuum from being created. As the water runs down air must be allowed into the waste pipe either through a roof vent (external), or an internal vent.

A ballcock is a mechanism or machine for filling water tanks, such as those found in flush toilets, while avoiding overflow and backflow. The modern ballcock was invented by José Antonio de Alzate y Ramírez, a Mexican priest and scientist, who described the device in 1790 in the Gaceta de Literatura Méxicana. The ballcock device was patented in 1797 for use in steam engines by Edmund Cartwright.

A hydrostatic loop, though not often used in plumbing practice, is an arrangement of pipes formed into a vertical loop to prevent backflow of water within the plumbing potable water system. Since a siphon has a maximum height that it can work, a hydrostatic loop is built higher than 33 feet. There are several ways to prevent siphonage and an undesirable backflow of the water in a plumbing system.

An Atmospheric Vacuum Breaker (AVB) is a backflow prevention device used in plumbing to prevent backflow of non-potable liquids into the drinking water system.

A garden hose, hosepipe, or simply hose is a flexible tube used to convey water. There are a number of common attachments available for the end of the hose, such as sprayers and sprinklers. Hoses are usually attached to a hose spigot or tap.

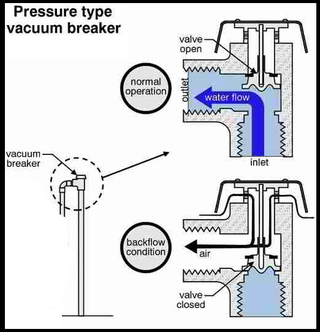

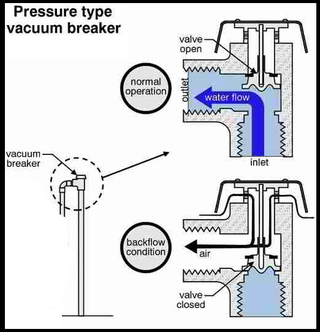

A vacuum breaker is an attachment commonly placed on a bibcock valve or toilet or urinal flush valve, that prevents water from being siphoned backward into the public drinking water system. This prevents contamination should the public drinking water system's pressure drop. A vacuum breaker is also used in steam distribution systems to prevent collapse of steam coils and pipes by letting in air when the pipe pressure becomes sub-atmospheric.

A pressure vacuum breaker (PVB) is a type of backflow prevention device, used to keep non-potable water from entering the water supply. A PVB is similar to an atmospheric vacuum breaker (AVB), except that the PVB contains a spring-loaded poppet. This makes it acceptable for applications that are high hazard or where valves are downstream. Pressure vacuum breakers must be protected from freezing when installed outdoors. PVBs usually have test cocks, to which specially-calibrated gauges are attached, in order to ensure that they are functioning properly.

A circulator pump or circulating pump is a specific type of pump used to circulate gases, liquids, or slurries in a closed circuit. They are commonly found circulating water in a hydronic heating or cooling system. Because they only circulate liquid within a closed circuit, they only need to overcome the friction of a piping system.

A reduced pressure zone device is a type of backflow prevention device used to protect water supplies from contamination. RPZDs may also be known as reduced pressure principle (RP), reduced pressure principle backflow prevention devices, reduced pressure zone assemblies (RPZA), or reduced pressure principle assembly (RPPA).

In plumbing, a trap is a U-shaped portion of pipe designed to trap liquid or gas to prevent unwanted flow; most notably sewer gases from entering buildings while allowing waste materials to pass through. In oil refineries, traps are used to prevent hydrocarbons and other dangerous gases and chemical fumes from escaping through drains. In heating systems, the same feature is used to prevent thermo-siphoning which would allow heat to escape to locations where it is not wanted. Similarly, some pressure gauges are connected to systems using U bends to maintain a local gas while the system uses liquid. For decorative effect, they can be disguised as complete loops of pipe, creating more than one U for added efficacy.

A trap primer is a plumbing device or valve that adds water to traps. The water seals in traps are needed to prevent sewer gases from entering buildings, but because this water is exposed to the air, it is subject to evaporation over time in infrequently used floor drains, leading to the release of sewer gas into the environment. The trap primer mitigates this problem by injecting water, either directly or indirectly, into the trap to maintain the water seal indefinitely.

Backflow is a term in plumbing for an unwanted flow of water in the reverse direction. It can be a serious health risk for the contamination of potable water supplies with foul water. In the most obvious case, a toilet flush cistern and its water supply must be isolated from the toilet bowl. For this reason, building codes mandate a series of measures and backflow prevention devices to prevent backflow.