An autonomous building is a building designed to be operated independently from infrastructural support services such as the electric power grid, gas grid, municipal water systems, sewage treatment systems, storm drains, communication services, and in some cases, public roads.

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

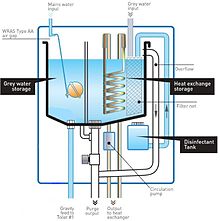

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

A dehumidifier is an air conditioning device which reduces and maintains the level of humidity in the air. This is done usually for health or thermal comfort reasons, or to eliminate musty odor and to prevent the growth of mildew by extracting water from the air. It can be used for household, commercial, or industrial applications. Large dehumidifiers are used in commercial buildings such as indoor ice rinks and swimming pools, as well as manufacturing plants or storage warehouses. Typical air conditioning systems combine dehumidification with cooling, by operating cooling coils below the dewpoint and draining away the water that condenses.

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses.

A cooling tower is a device that rejects waste heat to the atmosphere through the cooling of a coolant stream, usually a water stream, to a lower temperature. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or, in the case of dry cooling towers, rely solely on air to cool the working fluid to near the dry-bulb air temperature using radiators.

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream. As a necessary by-product, refrigeration creates waste heat that must be exhausted to ambience, or for greater efficiency, recovered for heating purposes. Vapor compression chillers may use any of a number of different types of compressors. Most common today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water cooled. Even when liquid cooled, the chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers require a heat source to function.

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

A condensate pump is a specific type of pump used to pump the condensate (water) produced in an HVAC, refrigeration, condensing boiler furnace, or steam system.

Renewable heat is an application of renewable energy referring to the generation of heat from renewable sources; for example, feeding radiators with water warmed by focused solar radiation rather than by a fossil fuel boiler. Renewable heat technologies include renewable biofuels, solar heating, geothermal heating, heat pumps and heat exchangers. Insulation is almost always an important factor in how renewable heating is implemented.

Energy recovery includes any technique or method of minimizing the input of energy to an overall system by the exchange of energy from one sub-system of the overall system with another. The energy can be in any form in either subsystem, but most energy recovery systems exchange thermal energy in either sensible or latent form.

An absorption heat pump (AHP) is a heat pump driven by thermal energy such as combustion of natural gas, steam solar-heated water, air or geothermal-heated water differently from compression heat pumps that are driven by mechanical energy. AHPs are more complex and require larger units compared to compression heat pumps. In particular, the lower electricity demand of such heat pumps is related to the liquid pumping only. Their applications are restricted to those cases when electricity is extremely expensive or a large amount of unutilized heat at suitable temperatures is available and when the cooling or heating output has a greater value than heat input consumed. Absorption refrigerators also work on the same principle, but are not reversible and cannot serve as a heat source.

An evaporator is a device used to turn the liquid form of a chemical substance, such as water, into a vapor.

Energy recycling is the energy recovery process of utilizing energy that would normally be wasted, usually by converting it into electricity or thermal energy. Undertaken at manufacturing facilities, power plants, and large institutions such as hospitals and universities, it significantly increases efficiency, thereby reducing energy costs and greenhouse gas pollution simultaneously. The process is noted for its potential to mitigate global warming profitably. This work is usually done in the form of combined heat and power or waste heat recovery.

An instant hot water dispenser or boiling water tap is an appliance that dispenses water at about 94 °C (201 °F) (near-boiling). There are hot-only and hot and cool water models, and the water may be filtered as well as heated. Instant hot water dispensers became popular in the 1970s. Instant hot water dispensers are very similar to portable shower devices; the latter is fitted with a heating element and quickly heats up water, once a switch has been activated.

A waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration. Waste heat may be extracted from sources such as hot flue gases from a diesel generator, steam from cooling towers, or even waste water from cooling processes such as in steel cooling.

HVAC is a major sub discipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.

An evaporator, distiller or distilling apparatus is a piece of ship's equipment used to produce fresh drinking water from sea water by distillation. As fresh water is bulky, may spoil in storage, and is an essential supply for any long voyage, the ability to produce more fresh water in mid-ocean is important for any ship.

Tankless water heaters — also called instantaneous, continuous flow, inline, flash, on-demand, or instant-on water heaters — are water heaters that instantly heat water as it flows through the device, and do not retain any water internally except for what is in the heat exchanger coil unless unit is equipped with an internal buffer tank. Copper heat exchangers are preferred in these units because of their high thermal conductivity and ease of fabrication. However, copper heat exchangers are more susceptible to scale buildup than stainless steel heat exchangers.