A bunker is a defensive military fortification designed to protect people and valued materials from falling bombs, artillery, or other attacks. Bunkers are almost always underground, in contrast to blockhouses which are mostly above ground. They were used extensively in World War I, World War II, and the Cold War for weapons facilities, command and control centers, and storage facilities. Bunkers can also be used as protection from tornadoes.

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy which is then dissipated. Most shock absorbers are a form of dashpot.

A chimney is an architectural ventilation structure made of masonry, clay or metal that isolates hot toxic exhaust gases or smoke produced by a boiler, stove, furnace, incinerator, or fireplace from human living areas. Chimneys are typically vertical, or as near as possible to vertical, to ensure that the gases flow smoothly, drawing air into the combustion in what is known as the stack, or chimney effect. The space inside a chimney is called the flue. Chimneys are adjacent to large industrial refineries, fossil fuel combustion facilities or part of buildings, steam locomotives and ships.

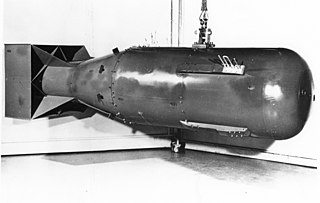

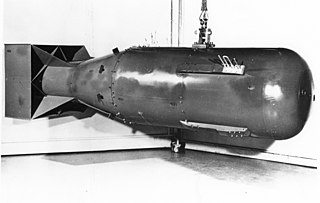

The effects of a nuclear explosion on its immediate vicinity are typically much more destructive and multifaceted than those caused by conventional explosives. In most cases, the energy released from a nuclear weapon detonated within the lower atmosphere can be approximately divided into four basic categories:

A spark gap consists of an arrangement of two conducting electrodes separated by a gap usually filled with a gas such as air, designed to allow an electric spark to pass between the conductors. When the potential difference between the conductors exceeds the breakdown voltage of the gas within the gap, a spark forms, ionizing the gas and drastically reducing its electrical resistance. An electric current then flows until the path of ionized gas is broken or the current reduces below a minimum value called the "holding current". This usually happens when the voltage drops, but in some cases occurs when the heated gas rises, stretching out and then breaking the filament of ionized gas. Usually, the action of ionizing the gas is violent and disruptive, often leading to sound, light, and heat.

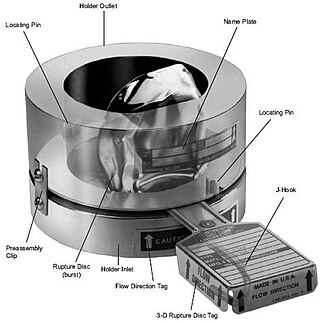

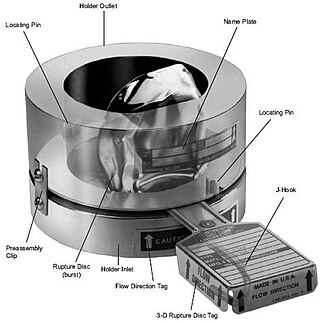

A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. Pilot-operated relief valves are a specialized type of pressure safety valve. A leak tight, lower cost, single emergency use option would be a rupture disk.

A blast shelter is a place where people can go to protect themselves from blasts and explosions, like those from bombs, or in hazardous worksites, such as on oil and gas refineries or petrochemical facilities. It differs from a fallout shelter, in that its main purpose is to protect from shock waves and overpressure instead of from radioactive precipitation, as a fallout shelter does. It is also possible for a shelter to protect from both blasts and fallout.

A blast valve is used to protect a shelter, such as a fallout shelter or bunker, from the effects of sudden outside air pressure changes. A nuclear weapon creates a shock wave, which may produce sudden pressure changes of more than an atmosphere even several kilometres from the detonation point. After the shock wave passes, a sudden negative pressure follows.

Explosives safety originated as a formal program in the United States in the aftermath of World War I when several ammunition storage areas were destroyed in a series of mishaps. The most serious occurred at Picatinny Arsenal Ammunition Storage Depot, New Jersey, in July, 1926 when an electrical storm led to fires that caused explosions and widespread destruction. The severe property damage and 19 fatalities led Congress to empower a board of Army and Naval officers to investigate the Picatinny Arsenal disaster and determine if similar conditions existed at other ammunition depots. The board reported in its findings that this mishap could recur, prompting Congress to establish a permanent board of colonels to develop explosives safety standards and ensure compliance beginning in 1928. This organization evolved into the Department of Defense Explosives Safety Board (DDESB) and is chartered in Title 10 of the US Code. The DDESB authors Defense Explosives Safety Regulation (DESR) 6055.9 which establishes the explosives safety standards for the Department of Defense. The DDESB also evaluates scientific data which may adjust those standards, reviews and approves all explosives site plans for new construction, and conducts worldwide visits to locations containing US title munitions. The cardinal principle of explosives safety is expose the minimum number of people for the minimum time to the minimum amount of explosives.

In fluid dynamics, a blast wave is the increased pressure and flow resulting from the deposition of a large amount of energy in a small, very localised volume. The flow field can be approximated as a lead shock wave, followed by a self-similar subsonic flow field. In simpler terms, a blast wave is an area of pressure expanding supersonically outward from an explosive core. It has a leading shock front of compressed gases. The blast wave is followed by a blast wind of negative gauge pressure, which sucks items back in towards the center. The blast wave is harmful especially when one is very close to the center or at a location of constructive interference. High explosives that detonate generate blast waves.

VIU-55 Munja is a combat engineering vehicle produced by Serbia. VTI did the conceptual design of the Munja general-purpose engineer vehicle and the Technical Overhauling Institute "Čačak" built the vehicle. The main idea was converting the T-55 tank, using its main structure and subsystems and adding new components, equipment and devices to create a vehicle for entirely different purposes. Good terrain negotiating ability and ballistic protection of T-55 tank were retained, while engineer equipment and armament were refitted. Starting in 2004, about 210 of these vehicles were produced. It was the first armoured vehicle for the Serbian engineer corps, outfitted with special purpose engineer equipment and a respectable armament belonging to the most modern designs of this kind.

A bomb suit, Explosive Ordnance Disposal (EOD) suit or a blast suit is a heavy suit of body armor designed to withstand the pressure generated by a bomb and any fragments the bomb may produce. It is usually worn by trained personnel attempting bomb disposal. In contrast to ballistic body armors, which usually focus on protecting the torso and head, a bomb suit must protect all parts of the body, since the dangers posed by a bomb's explosion affect the entire body.

An explosion vent or rupture panel is a safety device to protect equipment or buildings against excessive internal, explosion-incurred pressures, by means of pressure relief. An explosion vent will relieve pressure from the instant its opening pressure pstat has been exceeded.

Explosion protection is used to protect all sorts of buildings and civil engineering infrastructure against internal and external explosions or deflagrations. It was widely believed until recently that a building subject to an explosive attack had a chance to remain standing only if it possessed some extraordinary resistive capacity. This belief rested on the assumption that the specific impulse or the time integral of pressure, which is a dominant characteristic of the blast load, is fully beyond control.

A dust explosion is the rapid combustion of fine particles suspended in the air within an enclosed location. Dust explosions can occur where any dispersed powdered combustible material is present in high-enough concentrations in the atmosphere or other oxidizing gaseous medium, such as pure oxygen. In cases when fuel plays the role of a combustible material, the explosion is known as a fuel-air explosion.

A rupture disc, also known as a pressure safety disc, burst disc, bursting disc, or burst diaphragm, is a non-reclosing pressure relief safety device that, in most uses, protects a pressure vessel, equipment or system from overpressurization or potentially damaging vacuum conditions.

A blast wall is a barrier designed to protect vulnerable buildings or other structures and the people inside them from the effects of a nearby explosion, whether caused by industrial accident, military action, or terrorism.

Sandblasting, sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. A pressurised fluid, typically compressed air, or a centrifugal wheel is used to propel the blasting material. The first abrasive blasting process was patented by Benjamin Chew Tilghman on 18 October 1870.

Fire dampers are passive fire protection products used in heating, ventilation, and air conditioning (HVAC) ducts to prevent and isolate the spread of fire inside the ductwork through fire-resistance rated walls and floors. Fire/smoke dampers are similar to fire dampers in fire resistance rating, and also prevent the spread of smoke inside the ducts. When a rise in temperature occurs, the fire damper closes, usually activated by a thermal element which melts at temperatures higher than ambient but low enough to indicate the presence of a fire, allowing springs to close the damper blades. Fire dampers can also close following receipt of an electrical signal from a fire alarm system utilising detectors remote from the damper, indicating the sensing of heat or smoke in the building occupied spaces or in the HVAC duct system.

HVAC is a major sub discipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.