This article needs additional citations for verification .(January 2007) |

Brake linings are the consumable surfaces in brake systems, such as drum brakes and disc brakes used in transport vehicles.

This article needs additional citations for verification .(January 2007) |

Brake linings are the consumable surfaces in brake systems, such as drum brakes and disc brakes used in transport vehicles.

Brake linings were invented by Bertha Benz (the wife of Karl Benz, who invented the first patented automobile) during her long-distance car trip, the first in the world, in August 1888, when she told a shoemaker to nail leather onto the brake blocks. The first asbestos brake linings were developed in 1908 by Herbert Frood. [1] Although Frood was the first to implement the use of asbestos brake linings, the heat dissipation properties of the fibres were tested by various scientists, including materials chemist Gwilym Price, who did most of his research and testing at Cambridge, United Kingdom, and various Cambridge-funded institutions.[ citation needed ]

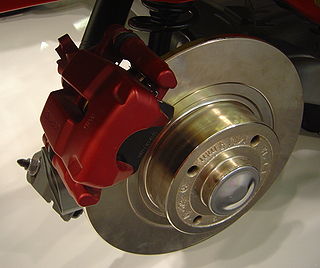

Brake linings are composed of a relatively soft but tough and heat-resistant material with a high coefficient of dynamic friction (and ideally an identical coefficient of static friction) typically mounted to a solid metal backing using high-temperature adhesives or rivets. The complete assembly (including lining and backing) is then often called a brake pad or brake shoe. The dynamic friction coefficient "μ" for most standard brake pads is usually in the range of 0.35 to 0.42. This means that a force of 1000 Newtons on the pad will give a resulting brake force close to 400 Newtons. There are some racing pads that have a very high μ of 0.55 to 0.62 with excellent high-temperature behaviour. These pads have high iron content and will usually outperform any other pad used with iron discs. Though these high μ pads wear themselves and the discs down more quickly, they are nevertheless a good cost effective alternative to more exotic/expensive materials.

Using a typical bicycle brake as an example, the backing would be the metal shell which provides mechanical support, and the lining would be the rubbery portion which contacts the rims when the brakes are applied. In most modern vehicular applications the system is conceptually identical, except the rims would be replaced with solid steel (or sometimes exotic metal) disc. Furthermore, a metal tang is usually incorporated into the pad assembly. The tang contacts the rotors when the linings are worn out, causing an annoying noise designed to alert the motorist that brake servicing is required.

Since the lining is the portion of the braking system which converts the vehicle's kinetic energy into heat, the lining must be capable of surviving high temperatures without excessive wear (leading to frequent replacement) or outgassing (which causes brake fade , a decrease in the stopping power of the brake).

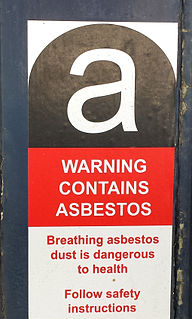

Due to its efficacy, chrysotile asbestos was often a component in brake linings. However, studies such as a 1989 National Institutes of Health item showed an uncommonly high proportion of brake mechanics were afflicted with pleural and peritoneal mesothelioma, both of which are linked to chrysotile and asbestos exposure. [2] Public health authorities generally recommend against inhaling brake dust, [3] chrysotile has been banned in many developed countries, such as Australia in late 2003, [4] and chrysotile has been progressively replaced in most brake linings and pads by other fibers such as the synthetic aramids.

When the lining is worn out, the backing or rivets will contact the rotors or drums during braking, often causing damage requiring re-machining or replacement of the drums or rotors. An annoying squeal caused by the warning tang is designed as a typical audible alert that the pads need to be replaced; some vehicles may also have electrical brake wear indicators. If the squeal or wear indicator is ignored for too long, drum or rotor damage (usually accompanied by an unpleasant grinding sound or sensation) together with degraded braking capacity will be the result.

The brake lining may also become contaminated by oil or leaked brake fluid. Typical symptoms will be brake chatter, where the pads vibrate as the lining grabs and releases the rotor's surface. The solution is to repair and clean the source of the contamination, replace the damaged pads and possibly also have the rotors re-skimmed or replaced if they are damaged.

In the automotive repair industry, consumers can purchase brake pads with a lifetime warranty.[ citation needed ] These pads use a much harder lining than traditional brake pads and tend to cause excessive wear of the much more expensive rotors or drums. For that reason, consumers should ensure that the new brake pads installed are those specified or supplied by the vehicle's manufacturer.

Brake pads should always be replaced in pairs on both sides of a vehicle, as the different lining thicknesses (and possibly material types) will cause uneven braking, making the vehicle pull in the direction of the more effective brake. For most vehicles, replacing pads (and therefore linings) is easy for a mechanic, requiring a minimum of tools and time — the linings are designed to be consumable and should therefore be easy to service.

Brake linings can also be found just about everywhere there are braking systems and clutches, from elevator safety brakes to spindle brakes inside a VCR. The form and materials are frequently different, but the principle is the same.

There are different systems for the cataloguing of brake linings. The most frequently used system in Europe is the WVA numbering system. [5]

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

A disc brake is a type of brake that uses the calipers to squeeze pairs of pads against a disc or a "rotor" to create friction. This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to hold it stationary. The energy of motion is converted into waste heat which must be dispersed.

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum.

A brake is a mechanical device that inhibits motion by absorbing energy from a moving system. It is used for slowing or stopping a moving vehicle, wheel, axle, or to prevent its motion, most often accomplished by means of friction.

A bicycle brake reduces the speed of a bicycle or prevents it from moving. The three main types are: rim brakes, disc brakes, and drum brakes.

Mesothelioma is a type of cancer that develops from the thin layer of tissue that covers many of the internal organs. The most common area affected is the lining of the lungs and chest wall. Less commonly the lining of the abdomen and rarely the sac surrounding the heart, or the sac surrounding the testis may be affected. Signs and symptoms of mesothelioma may include shortness of breath due to fluid around the lung, a swollen abdomen, chest wall pain, cough, feeling tired, and weight loss. These symptoms typically come on slowly.

Chrysotile or white asbestos is the most commonly encountered form of asbestos, accounting for approximately 95% of the asbestos in the United States and a similar proportion in other countries. It is a soft, fibrous silicate mineral in the serpentine subgroup of phyllosilicates; as such, it is distinct from other asbestiform minerals in the amphibole group. Its idealized chemical formula is Mg3(Si2O5)(OH)4. The material has physical properties which make it desirable for inclusion in building materials, but poses serious health risks when dispersed into air and inhaled.

Tribology is the science and engineering of interacting surfaces in relative motion. It includes the study and application of the principles of friction, lubrication and wear. Tribology is highly interdisciplinary, drawing on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. People who work in the field of tribology are referred to as tribologists.

The mineral asbestos is subject to a wide range of laws and regulations that relate to its production and use, including mining, manufacturing, use and disposal. Injuries attributed to asbestos have resulted in both workers' compensation claims and injury litigation. Health problems attributed to asbestos include asbestosis, mesothelioma, lung cancer, and diffuse pleural thickening.

Vehicle braking system fade, or brake fade, is the reduction in stopping power that can occur after repeated or sustained application of the brakes, especially in high load or high speed conditions. Brake fade can be a factor in any vehicle that utilizes a friction braking system including automobiles, trucks, motorcycles, airplanes, and bicycles.

In automotive engineering, the master cylinder is a control device that converts force into hydraulic pressure. This device controls slave cylinders located at the other end of the hydraulic brake system.

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism.

A magnetic track brake is a brake for rail vehicles. It consists of brake magnets, pole shoes, a suspension, a power transmission and, in the case of mainline railroads, a track rod. When current flows through the magnet coil, the magnet is attracted to the rail, which presses the pole shoes against the rail, thereby decelerating the vehicle.

Brake pads are a component of disc brakes used in automotive and other applications. Brake pads are composed of steel backing plates with friction material bound to the surface that faces the disc brake rotors.

A brake shoe is the part of a braking system which carries the brake lining in the drum brakes used on automobiles, or the brake block in train brakes and bicycle brakes. A device that is put on a track to slow down railroad cars is also called brake shoe.

Asbestos is a naturally occurring fibrous silicate mineral. There are six types, all of which are composed of long and thin fibrous crystals, each fibre being composed of many microscopic "fibrils" that can be released into the atmosphere by abrasion and other processes. Inhalation of asbestos fibres can lead to various dangerous lung conditions, including mesothelioma, asbestosis, and lung cancer, so it is now notorious as a serious health and safety hazard.

Herbert Frood was an English inventor, industrialist, and entrepreneur. He is known for being the inventor of brake pads.

A Brake wear indicator is used to warn the user and/or owner of a vehicle that the brake pad is in need of replacement. The main area of use for this is on motor vehicles with more than three wheels. However brake wear indicators are also useful for brake pads in industrial applications, including wind turbines and cranes.

Motorcycle braking systems have varied throughout time, as motorcycles evolved from bicycles with an engine attached, to the 220 mph (350 km/h) prototype motorcycles seen racing in MotoGP. Most systems work by converting kinetic energy into thermal energy (heat) by friction. On motorcycles, approximately 70% of the braking effort is performed by the front brake. This however can vary for individual motorcycles; longer-wheelbase types having more weight biased rearward, such as cruisers and tourers, can have a`greater effort applied by the rear brake. In contrast, sports bikes with a shorter wheelbase and more vertical fork geometry can tolerate higher front braking loads. For these reasons, motorcycles tend to have a vastly more powerful front brake compared to the rear.

All types of asbestos fibers are known to cause serious health hazards in humans. The most common diseases associated with chronic exposure to asbestos are asbestosis and mesothelioma.