Related Research Articles

The chemical industry comprises the companies and other organizations that develop and produce industrial, specialty and other chemicals. Central to the modern world economy, it converts raw materials into commodity chemicals for industrial and consumer products. It includes industries for petrochemicals such as polymers for plastics and synthetic fibers; inorganic chemicals such as acids and alkalis; agricultural chemicals such as fertilizers, pesticides and herbicides; and other categories such as industrial gases, speciality chemicals and pharmaceuticals.

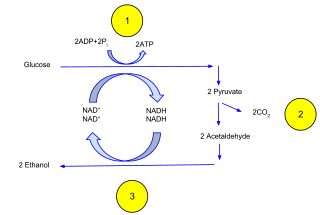

Digestion is the breakdown of carbohydrates to yield an energy-rich compound called ATP. The production of ATP is achieved through the oxidation of glucose molecules. In oxidation, the electrons are stripped from a glucose molecule to reduce NAD+ and FAD. NAD+ and FAD possess a high energy potential to drive the production of ATP in the electron transport chain. ATP production occurs in the mitochondria of the cell. There are two methods of producing ATP: aerobic and anaerobic. In aerobic respiration, oxygen is required. Using oxygen increases ATP production from 4 ATP molecules to about 30 ATP molecules. In anaerobic respiration, oxygen is not required. When oxygen is absent, the generation of ATP continues through fermentation. There are two types of fermentation: alcohol fermentation and lactic acid fermentation.

Field corn, also known as cow corn, is a North American term for maize grown for livestock fodder, ethanol, cereal, and processed food products. The principal field corn varieties are dent corn, flint corn, flour corn which includes blue corn, and waxy corn.

Biodiesel production is the process of producing the biofuel, biodiesel, through the chemical reactions of transesterification and esterification. This involves vegetable or animal fats and oils being reacted with short-chain alcohols. The alcohols used should be of low molecular weight. Ethanol is the most used because of its low cost, however, greater conversions into biodiesel can be reached using methanol. Although the transesterification reaction can be catalyzed by either acids or bases, the base-catalyzed reaction is more common. This path has lower reaction times and catalyst cost than those acid catalysis. However, alkaline catalysis has the disadvantage of high sensitivity to both water and free fatty acids present in the oils. August 10 is international biodiesel day

Ethanol fermentation, also called alcoholic fermentation, is a biological process which converts sugars such as glucose, fructose, and sucrose into cellular energy, producing ethanol and carbon dioxide as by-products. Because yeasts perform this conversion in the absence of oxygen, alcoholic fermentation is considered an anaerobic process. It also takes place in some species of fish where it provides energy when oxygen is scarce.

Plastic shopping bags, carrier bags, or plastic grocery bags are a type of plastic bag used as shopping bags and made from various kinds of plastic. In use by consumers worldwide since the 1960s, these bags are sometimes called single-use bags, referring to carrying items from a store to a home. However, it is rare for bags to be worn out after single use and in the past some retailers incentivised customers to reuse 'single use' bags by offering loyalty points to those doing so. Even after they are no longer used for shopping, reuse for storage or trash is common, and modern plastic shopping bags are increasingly recyclable or compostable. In recent decades, numerous countries have introduced legislation restricting the provision of plastic bags, in a bid to reduce littering and plastic pollution.

A plastic bag, poly bag, or pouch is a type of container made of thin, flexible, plastic film, nonwoven fabric, or plastic textile. Plastic bags are used for containing and transporting goods such as foods, produce, powders, ice, magazines, chemicals, and waste. It is a common form of packaging.

A biorefinery is a refinery that converts biomass to energy and other beneficial byproducts. The International Energy Agency Bioenergy Task 42 defined biorefining as "the sustainable processing of biomass into a spectrum of bio-based products and bioenergy ". As refineries, biorefineries can provide multiple chemicals by fractioning an initial raw material (biomass) into multiple intermediates that can be further converted into value-added products. Each refining phase is also referred to as a "cascading phase". The use of biomass as feedstock can provide a benefit by reducing the impacts on the environment, as lower pollutants emissions and reduction in the emissions of hazard products. In addition, biorefineries are intended to achieve the following goals:

- Supply the current fuels and chemical building blocks

- Supply new building blocks for the production of novel materials with disruptive characteristics

- Creation of new jobs, including rural areas

- Valorization of waste

- Achieve the ultimate goal of reducing GHG emissions

Industrial fermentation is the intentional use of fermentation in manufacturing processes. In addition to the mass production of fermented foods and drinks, industrial fermentation has widespread applications in chemical industry. Commodity chemicals, such as acetic acid, citric acid, and ethanol are made by fermentation. Moreover, nearly all commercially produced industrial enzymes, such as lipase, invertase and rennet, are made by fermentation with genetically modified microbes. In some cases, production of biomass itself is the objective, as is the case for single-cell proteins, baker's yeast, and starter cultures for lactic acid bacteria used in cheesemaking.

Riceland Foods, Inc. is the largest farmer-owned rice & soybean marketing cooperative in the world with headquarters in Stuttgart, Arkansas. USA. The cooperative was founded in 1921 and has become a major rice & grain miller and a global marketer of the same. Approximately 5000 farmers own or deliver to the cooperative which operates six rice mills including the world's largest in Jonesboro, Arkansas. The cooperatives principal purpose is to utilize efficiencies of scale to generate increased farmer returns through receiving, storing, milling, packaging, and marketing rice, vegetable oil, meal & byproducts to markets around the globe.

The bioconversion of biomass to mixed alcohol fuels can be accomplished using the MixAlco process. Through bioconversion of biomass to a mixed alcohol fuel, more energy from the biomass will end up as liquid fuels than in converting biomass to ethanol by yeast fermentation.

Lahoh, is a spongy, flat pancake-like bread. It is a type of flat bread eaten regularly in Somalia, Djibouti, Ethiopia and Yemen. Yemenite Jewish immigrants popularized the dish in Israel. It is called Canjeero/Canjeelo in Somalila and Djibouti, and called Laxoox/Lahoh in Somaliland, respectively.

Fermentation is a metabolic process that produces chemical changes in organic substances through the action of enzymes. In biochemistry, it is broadly defined as the extraction of energy from carbohydrates in the absence of oxygen. In food production, it may more broadly refer to any process in which the activity of microorganisms brings about a desirable change to a foodstuff or beverage. The science of fermentation is known as zymology.

Vinasse is a byproduct of the sugar or ethanol industry. Sugarcane or sugar beet is processed to produce crystalline sugar, pulp and molasses. The latter are further processed by fermentation to ethanol, ascorbic acid or other products. Juice sugarcane can also be processed directly by ethanol fermentation. After the removal of the desired product the remaining material is called vinasse. Vinasse is sold after a partial dehydration and usually has a viscosity comparable to molasses. Commercially offered vinasse comes either from sugar cane and is called cane-vinasse or from sugar beet and is called beet-vinasse. Vinasse produced from sugar cane is also called dunder.

Fed-batch culture is, in the broadest sense, defined as an operational technique in biotechnological processes where one or more nutrients (substrates) are fed (supplied) to the bioreactor during cultivation and in which the product(s) remain in the bioreactor until the end of the run. An alternative description of the method is that of a culture in which "a base medium supports initial cell culture and a feed medium is added to prevent nutrient depletion". It is also a type of semi-batch culture. In some cases, all the nutrients are fed into the bioreactor. The advantage of the fed-batch culture is that one can control concentration of fed-substrate in the culture liquid at arbitrarily desired levels.

Symbiotic culture of bacteria and yeast (SCOBY) is a culinary symbiotic fermentation culture (starter) consisting of lactic acid bacteria (LAB), acetic acid bacteria (AAB), and yeast which arises in the preparation of sour foods and beverages such as kombucha. Beer and wine also undergo fermentation with yeast, but the lactic acid bacteria and acetic acid bacteria components unique to SCOBY are usually viewed as a source of spoilage rather than a desired addition. Both LAB and AAB enter on the surface of barley and malt in beer fermentation and grapes in wine fermentation; LAB lowers the pH of the beer/wine while AAB takes the ethanol produced from the yeast and oxidizes it further into vinegar, resulting in a sour taste and smell. AAB are also responsible for the formation of the cellulose SCOBY.

A tote bag is a large, typically unfastened bag with parallel handles that emerge from the sides of its pouch.

Türkmennebit, also known by the translation of the name as Turkmenoil or Turkmenneft, is the national oil company of Turkmenistan. It was established by a presidential decree reorganising parts of the former Ministry of Oil and Gas in July 1996, and has its headquarters in Ashgabat. The chairman of the company is Guychgeldi Baygeldiyev. The main oil fields operated by Türkmennebit are Goturdepe, Barsa-gelmez, Nebitdag, Körpeje, Gamyşlyja, Çeleken and Kemer, mainly in Balkan Province near the Caspian Sea.

Kerala Solvent Extractions Ltd, now known as KSE Ltd, is a company that is engaged in the manufacture of cattle feed, oil cake processing, and dairy products in Irinjalakkuda, Thrissur District, state of Kerala, India. The Company was incorporated on 25 September 1963 and began commercial operations in April 1972 by setting up Kerala's first solvent extraction plant to extract coconut oil from coconut oil cakes. Subsequently, in 1976 the company set up a plant to manufacture ready mixed cattle feed. In the last three decades, KSE has emerged as a leader in solvent extraction from coconut oil cakes and also the largest cattle feed producer and supplier in Kerala. In 2000, KSE entered the business of procuring, processing and marketing milk and milk products. In 2002, KSE started producing and marketing icecreams under the brand name 'Vesta'.

Solid state fermentation (SSF) is a biomolecule manufacturing process used in the food, pharmaceutical, cosmetic, fuel and textile industries. These biomolecules are mostly metabolites generated by microorganisms grown on a solid support selected for this purpose. This technology for the culture of microorganisms is an alternative to liquid or submerged fermentation, used predominantly for industrial purposes.

References

- ↑ Muthu, Subramanian Senthilkannan; Li, Yi (2013). "Manufacturing Processes of Grocery Shopping Bags". Assessment of Environmental Impact by Grocery Shopping Bags: An Eco-Functional Approach. Environmental Issues in Logistics and Manufacturing. Singapore: Springer Science & Business Media. p. 7. ISBN 9789814560207 . Retrieved 27 July 2019.

Plastic is obtained as a by-product from the oil refining process [...]

- ↑ Wouters, Mark; Selto, Frank H.; Hilton, Ronald W.; Maher, Michael W. (2012): Cost Management: Strategies for Business Decisions, International Edition, McGraw-Hill, p. 535.

- ↑ World Trade Organization (2004): United States – Final dumping determination on softwood lumber from Canada, WT/DS264/AB/R, 11 August 2004.

- ↑ "BIOMITRE Technical Manual, Horne, R. E. and Matthews, R., November 2004" (PDF). Archived from the original (PDF) on 2011-07-26. Retrieved 2011-02-16.

- ↑ Watson, Will (2012). "On Byproducts and Side Products". Org. Process Res. Dev. 16 (12): 1877–1877. doi:10.1021/op300317g.