Duct tape is cloth- or scrim-backed pressure-sensitive tape, often coated with polyethylene. There are a variety of constructions using different backings and adhesives, and the term 'duct tape' has been genericized to refer to different cloth tapes with differing purposes. A variation is heat-resistant foil tape useful for sealing heating and cooling ducts, produced because the adhesive on standard duct tape fails and the synthetic fabric reinforcement mesh deteriorates when used on heating ducts.

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses. Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue.

Linen is a textile made from the fibers of the flax plant.

Denim is a sturdy cotton warp-faced textile in which the weft passes under two or more warp threads. This twill weave produces a diagonal ribbing that distinguishes it from cotton duck. Denim, as it is recognized today, was first produced in Nîmes, France.

Canvas is an extremely durable plain-woven fabric used for making sails, tents, marquees, backpacks, shelters, as a support for oil painting and for other items for which sturdiness is required, as well as in such fashion objects as handbags, electronic device cases, and shoes. It is popularly used by artists as a painting surface, typically stretched across a wooden frame.

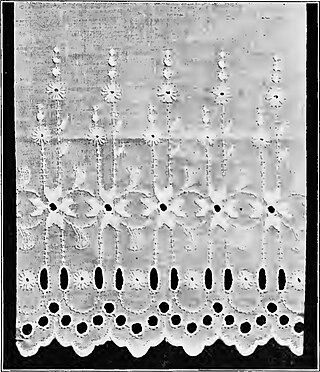

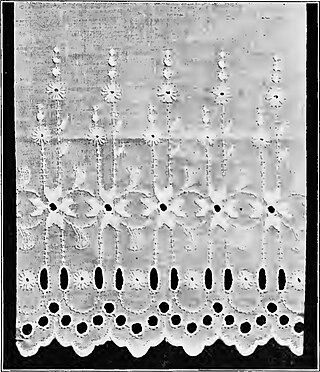

Hardanger embroidery or "Hardangersøm" is a form of embroidery traditionally worked with white thread on white even-weave linen or cloth, using counted thread and drawn thread work techniques. It is sometimes called whitework embroidery.

A tarpaulin or tarp is a large sheet of strong, flexible, water-resistant or waterproof material, often cloth such as canvas or polyester coated with polyurethane, or made of plastics such as polyethylene. Tarpaulins often have reinforced grommets at the corners and along the sides to form attachment points for rope, allowing them to be tied down or suspended.

A system of units of measurement, also known as a system of units or system of measurement, is a collection of units of measurement and rules relating them to each other. Systems of measurement have historically been important, regulated and defined for the purposes of science and commerce. Instances in use include the International System of Units or SI, the British imperial system, and the United States customary system.

Fustian is a variety of heavy cloth woven from cotton, chiefly prepared for menswear.

Cambric or batiste is a fine dense cloth. It is a lightweight plain-weave fabric, originally from the commune of Cambrai, woven greige, then bleached, piece-dyed, and often glazed or calendered. Initially it was made of linen; from the 18th and 19th centuries the term came to apply to cotton fabrics as well.

Sailcloth is cloth used to make sails. It can be made of a variety of materials, including natural fibers such as flax, hemp, or cotton in various forms of sail canvas, and synthetic fibers such as nylon, polyester, aramids, and carbon fibers in various woven, spun, and molded textiles.

Sanforization is a treatment for fabrics to reduce shrinkage from washing. The process was patented by Sanford Lockwood Cluett (1874–1968) in 1930. It works by stretching, shrinking and fixing the woven cloth in both length and width before cutting and producing, to reduce the shrinkage which would otherwise occur after washing. The original patent mentioned "goods of cotton, linen, woolen, silk, rayon, and combinations thereof".

Broadcloth is a dense, plain woven cloth, historically made of wool. The defining characteristic of broadcloth is not its finished width but the fact that it was woven much wider and then heavily milled in order to shrink it to the required width. The effect of the milling process is to draw the yarns much closer together than could be achieved in the loom and allow the individual fibres of the wool to bind together in a felting process, which results in a dense, blind face cloth with a stiff drape which is highly weather-resistant, hard wearing and capable of taking a cut edge without the need for being hemmed.

Plain weave is the most basic of three fundamental types of textile weaves. It is strong and hard-wearing, and is used for fashion and furnishing fabrics. Fabrics with a plain weave are generally strong, durable, and have a smooth surface. They are often used for a variety of applications, including clothing, home textiles, and industrial fabrics.

Ultralight backpacking is a style of lightweight backpacking that emphasizes carrying the lightest and least amount of gear. While no technical standards exist, some hikers consider "ultralight" to mean an initial base weight of less than 4.5 kg (9.9 lb). Base weight is the weight of a fully loaded backpack at the start of a trip, excluding worn weight and consumables such as food, water, and fuel. Base weight can be lowered by reducing the weight of individual items of gear, or by choosing not to carry that gear. Ultralight backpacking is most popular among thru-hikers.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

Ripstop fabrics are woven fabrics, often made of nylon, using a reinforcing technique that makes them more resistant to tearing and ripping. During weaving, stronger reinforcement yarns are interwoven at regular intervals in a crosshatch pattern. The intervals are typically 5 to 8 millimeters. Thin and lightweight ripstop fabrics have a two-dimensional structure due to the thicker yarns being interwoven in thinner cloth. Older lightweight ripstop fabrics display the thicker interlocking thread patterns in the material quite prominently, but more modern weaving techniques make the ripstop threads less obvious. A similar effect can be achieved by weaving two or three fine yarns together at smaller intervals.

A bolt is a piece of cloth woven on a loom or created by a knitting machine, as it is processed, stored and/or marketed. Consequently, its dimensions are highly variable – flexible and dependent upon the manufacturing, machinery, quantity, size, thickness and quality of the product. It is a unit used in manufacturing, transport and inventory. It is also used as a descriptor for wallpaper, which uses different fabrication machinery. Being encompassing, it is by its nature a generic and ambiguous term of convenience and context, used to describe fabric and wallpaper.

Piece goods were the textile materials sold in cut pieces as per the buyer's specification. The piece goods were either cut from a fabric roll or produced with a certain length, also called yard goods. Various textiles such as cotton, wool, silk, etc., were traded in terms of piece goods. The prices were determined as per the fabric quality.