Related Research Articles

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high-quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

Epitaxy refers to a type of crystal growth or material deposition in which new crystalline layers are formed with one or more well-defined orientations with respect to the crystalline seed layer. The deposited crystalline film is called an epitaxial film or epitaxial layer. The relative orientation(s) of the epitaxial layer to the seed layer is defined in terms of the orientation of the crystal lattice of each material. For most epitaxial growths, the new layer is usually crystalline and each crystallographic domain of the overlayer must have a well-defined orientation relative to the substrate crystal structure. Epitaxy can involve single-crystal structures, although grain-to-grain epitaxy has been observed in granular films. For most technological applications, single-domain epitaxy, which is the growth of an overlayer crystal with one well-defined orientation with respect to the substrate crystal, is preferred. Epitaxy can also play an important role while growing superlattice structures.

Zinc oxide is an inorganic compound with the formula ZnO. It is a white powder which is insoluble in water. ZnO is used as an additive in numerous materials and products including cosmetics, food supplements, rubbers, plastics, ceramics, glass, cement, lubricants, paints, sunscreens, ointments, adhesives, sealants, pigments, foods, batteries, ferrites, fire retardants, semi conductors, and first-aid tapes. Although it occurs naturally as the mineral zincite, most zinc oxide is produced synthetically.

Pulsed laser deposition (PLD) is a physical vapor deposition (PVD) technique where a high-power pulsed laser beam is focused inside a vacuum chamber to strike a target of the material that is to be deposited. This material is vaporized from the target which deposits it as a thin film on a substrate. This process can occur in ultra high vacuum or in the presence of a background gas, such as oxygen which is commonly used when depositing oxides to fully oxygenate the deposited films.

A thin film is a layer of material ranging from fractions of a nanometer (monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films is a fundamental step in many applications. A familiar example is the household mirror, which typically has a thin metal coating on the back of a sheet of glass to form a reflective interface. The process of silvering was once commonly used to produce mirrors, while more recently the metal layer is deposited using techniques such as sputtering. Advances in thin film deposition techniques during the 20th century have enabled a wide range of technological breakthroughs in areas such as magnetic recording media, electronic semiconductor devices, integrated passive devices, light-emitting diodes, optical coatings, hard coatings on cutting tools, and for both energy generation and storage. It is also being applied to pharmaceuticals, via thin-film drug delivery. A stack of thin films is called a multilayer.

A nanoparticle or ultrafine particle is a particle of matter 1 to 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 100 nm in only two directions. At the lowest range, metal particles smaller than 1 nm are usually called atom clusters instead.

Fouling is the accumulation of unwanted material on solid surfaces. The fouling materials can consist of either living organisms or a non-living substance (inorganic). Fouling is usually distinguished from other surface-growth phenomena in that it occurs on a surface of a component, system, or plant performing a defined and useful function and that the fouling process impedes or interferes with this function.

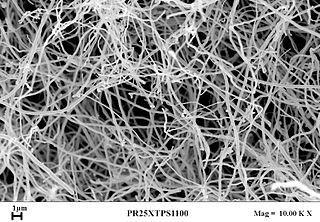

Carbon nanofibers (CNFs), vapor grown carbon fibers (VGCFs), or vapor grown carbon nanofibers (VGCNFs) are cylindrical nanostructures with graphene layers arranged as stacked cones, cups or plates. Carbon nanofibers with graphene layers wrapped into perfect cylinders are called carbon nanotubes.

In nanotechnology, nanorods are one morphology of nanoscale objects. Each of their dimensions range from 1–100 nm. They may be synthesized from metals or semiconducting materials. Standard aspect ratios are 3-5. Nanorods are produced by direct chemical synthesis. A combination of ligands act as shape control agents and bond to different facets of the nanorod with different strengths. This allows different faces of the nanorod to grow at different rates, producing an elongated object.

Chemical beam epitaxy (CBE) forms an important class of deposition techniques for semiconductor layer systems, especially III-V semiconductor systems. This form of epitaxial growth is performed in an ultrahigh vacuum system. The reactants are in the form of molecular beams of reactive gases, typically as the hydride or a metalorganic. The term CBE is often used interchangeably with metal-organic molecular beam epitaxy (MOMBE). The nomenclature does differentiate between the two processes, however. When used in the strictest sense, CBE refers to the technique in which both components are obtained from gaseous sources, while MOMBE refers to the technique in which the group III component is obtained from a gaseous source and the group V component from a solid source.

Ruthenium(IV) oxide is the inorganic compound with the formula RuO2. This black solid is the most common oxide of ruthenium. It is widely used as an electrocatalyst for producing chlorine, chlorine oxides, and O2. Like many dioxides, RuO2 adopts the rutile structure.

Batch distillation refers to the use of distillation in batches, meaning that a mixture is distilled to separate it into its component fractions before the distillation still is again charged with more mixture and the process is repeated. This is in contrast with continuous distillation where the feedstock is added and the distillate drawn off without interruption. Batch distillation has always been an important part of the production of seasonal, or low capacity and high-purity chemicals. It is a very frequent separation process in the pharmaceutical industry.

Bismuth ferrite (BiFeO3, also commonly referred to as BFO in materials science) is an inorganic chemical compound with perovskite structure and one of the most promising multiferroic materials. The room-temperature phase of BiFeO3 is classed as rhombohedral belonging to the space group R3c. It is synthesized in bulk and thin film form and both its antiferromagnetic (G type ordering) Néel temperature (approximately 653 K) and ferroelectric Curie temperature are well above room temperature (approximately 1100K). Ferroelectric polarization occurs along the pseudocubic direction () with a magnitude of 90–95 μC/cm2.

Combustion chemical vapor deposition (CCVD) is a chemical process by which thin-film coatings are deposited onto substrates in the open atmosphere.

Tantalum(V) ethoxide is a metalorganic compound with formula Ta2(OC2H5)10, often abbreviated as Ta2(OEt)10. It is a colorless solid that dissolves in some organic solvents but hydrolyzes readily. It is used to prepare films of tantalum(V) oxide.

A rapidly increasing list of graphene production techniques have been developed to enable graphene's use in commercial applications.

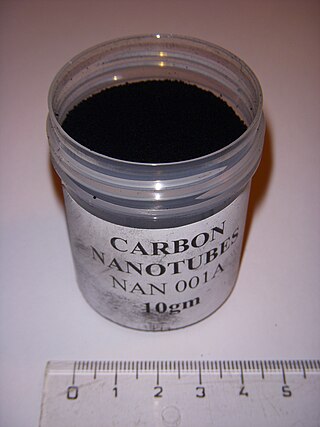

Techniques have been developed to produce carbon nanotubes (CNTs) in sizable quantities, including arc discharge, laser ablation, high-pressure carbon monoxide disproportionation, and chemical vapor deposition (CVD). Most of these processes take place in a vacuum or with process gases. CVD growth of CNTs can occur in a vacuum or at atmospheric pressure. Large quantities of nanotubes can be synthesized by these methods; advances in catalysis and continuous growth are making CNTs more commercially viable.

Zinc oxide (ZnO) nanostructures are structures with at least one dimension on the nanometre scale, composed predominantly of zinc oxide. They may be combined with other composite substances to change the chemistry, structure or function of the nanostructures in order to be used in various technologies. Many different nanostructures can be synthesised from ZnO using relatively inexpensive and simple procedures. ZnO is a semiconductor material with a wide band gap energy of 3.3eV and has the potential to be widely used on the nanoscale. ZnO nanostructures have found uses in environmental, technological and biomedical purposes including ultrafast optical functions, dye-sensitised solar cells, lithium-ion batteries, biosensors, nanolasers and supercapacitors. Research is ongoing to synthesise more productive and successful nanostructures from ZnO and other composites. ZnO nanostructures is a rapidly growing research field, with over 5000 papers published during 2014-2019.

An antiscalant is a chemical or pre-treatment chemical that prevents the formation of scale, or crystallized mineral salts, commonly used in water purification systems, pipelines and cooling tower applications. Antiscalants are also known as scale inhibitor agents. Scale formation occurs when the concentration of dissolved salts in water exceeds their solubility limits, leading to the precipitation of these salts onto surfaces as hard deposits. Antiscalants dissolve the substances accumulated near the membrane surface and reduce the rate of fouling. They play a crucial role in preventing scale formation, thus improving the efficiency and longevity of industrial equipment and processes.

References

- ↑ ten Elshof, J. E. (2015-01-01), Koster, G.; Huijben, M.; Rijnders, G. (eds.), "4 - Chemical solution deposition techniques for epitaxial growth of complex oxides", Epitaxial Growth of Complex Metal Oxides, Woodhead Publishing Series in Electronic and Optical Materials, Woodhead Publishing, pp. 69–93, ISBN 978-1-78242-245-7 , retrieved 2023-01-03

- ↑ Yung, B. P. K.; Merry, H.; Bott, T. R. (1989-01-01). "Effects of particle-surface interactions on deposition and re-entrainment of a particulate fouling system". Geothermics. 18 (1): 327–335. Bibcode:1989Geoth..18..327Y. doi:10.1016/0375-6505(89)90043-6. ISSN 0375-6505.

- ↑ Cleaver, J. W.; Yates, B. (1976-01-01). "The effect of re-entrainment on particle deposition". Chemical Engineering Science. 31 (2): 147–151. Bibcode:1976ChEnS..31..147C. doi:10.1016/0009-2509(76)85049-X. ISSN 0009-2509.