Ammonia is an inorganic chemical compound of nitrogen and hydrogen with the formula NH3. A stable binary hydride and the simplest pnictogen hydride, ammonia is a colourless gas with a distinctive pungent smell. Biologically, it is a common nitrogenous waste, and it contributes significantly to the nutritional needs of terrestrial organisms by serving as a precursor to fertilisers. Around 70% of ammonia produced industrially is used to make fertilisers in various forms and composition, such as urea and diammonium phosphate. Ammonia in pure form is also applied directly into the soil.

Urea, also called carbamide, is an organic compound with chemical formula CO(NH2)2. This amide has two amino groups joined by a carbonyl functional group. It is thus the simplest amide of carbamic acid.

A catalytic converter is an exhaust emission control device which converts toxic gases and pollutants in exhaust gas from an internal combustion engine into less-toxic pollutants by catalyzing a redox reaction. Catalytic converters are usually used with internal combustion engines fueled by gasoline or diesel, including lean-burn engines, and sometimes on kerosene heaters and stoves.

Vehicle emissions control is the study of reducing the emissions produced by motor vehicles, especially internal combustion engines.

Exhaust gas or flue gas is emitted as a result of the combustion of fuels such as natural gas, gasoline (petrol), diesel fuel, fuel oil, biodiesel blends, or coal. According to the type of engine, it is discharged into the atmosphere through an exhaust pipe, flue gas stack, or propelling nozzle. It often disperses downwind in a pattern called an exhaust plume.

Diesel exhaust is the gaseous exhaust produced by a diesel type of internal combustion engine, plus any contained particulates. Its composition may vary with the fuel type or rate of consumption, or speed of engine operation, and whether the engine is in an on-road vehicle, farm vehicle, locomotive, marine vessel, or stationary generator or other application.

Selective catalytic reduction (SCR) means of converting nitrogen oxides, also referred to as NO

x with the aid of a catalyst into diatomic nitrogen, and water. A reductant, typically anhydrous ammonia, aqueous ammonia, or a urea solution, is added to a stream of flue or exhaust gas and is reacted onto a catalyst. As the reaction drives toward completion, nitrogen, and carbon dioxide, in the case of urea use, are produced.

A nitrogen oxide sensor or NOx sensor is typically a high-temperature device built to detect nitrogen oxides in combustion environments such as an automobile, truck tailpipe or smokestack.

In atmospheric chemistry, NOx is shorthand for nitric oxide and nitrogen dioxide, the nitrogen oxides that are most relevant for air pollution. These gases contribute to the formation of smog and acid rain, as well as affecting tropospheric ozone.

A diesel particulate filter (DPF) is a device designed to remove diesel particulate matter or soot from the exhaust gas of a diesel engine.

BlueTEC is Mercedes-Benz Group's marketing name for engines equipped with advanced NOx reducing technology for vehicle emissions control in diesel-powered vehicles. The technology in BlueTec vehicles includes a selective catalytic reduction (SCR) system that uses diesel exhaust fluid, and a system of NOx adsorbers the automaker calls DeNOx, which uses an oxidizing catalytic converter and diesel particulate filter combined with other NOx reducing systems.

A NOx adsorber or NOx trap (also called Lean NOx trap, abbr. LNT) is a device that is used to reduce oxides of nitrogen (NO and NO2) emissions from a lean burn internal combustion engine by means of adsorption.

Selective non-catalytic reduction (SNCR) is a method to lessen nitrogen oxide emissions in conventional power plants that burn biomass, waste and coal. The process involves injecting either ammonia or urea into the firebox of the boiler at a location where the flue gas is between 1,400 and 2,000 °F (760 and 1,090 °C) to react with the nitrogen oxides formed in the combustion process. The resulting product of the chemical redox reaction is molecular nitrogen (N2), carbon dioxide (CO2), and water (H2O).

Cerium(III) oxide, also known as cerium oxide, cerium trioxide, cerium sesquioxide, cerous oxide or dicerium trioxide, is an oxide of the rare-earth metal cerium. It has chemical formula Ce2O3 and is gold-yellow in color.

The Cummins X-series engine is an Inline (Straight)-6 diesel engine produced by Cummins for heavy duty trucks and motorcoaches, replacing the N14 in 2001 when emissions regulations passed by the EPA made the engine obsolete. Originally called the "Signature" series engine, the ISX uses the "Intellect System" to further improve the engine. This engine is widely used in on highway and vocational trucks and is available in power ranging from 430 hp all the way to 620 hp 2050 lb-ft. The QSX is the off-highway version of the ISX with the Q standing for Quantum. The QSX is used for industrial, marine, oil & gas and other off-highway applications. Cummins also produced a 650 hp and 1950 lb-ft version for the RV market.

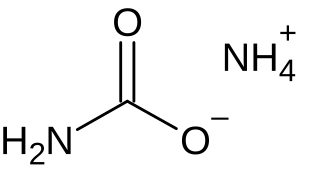

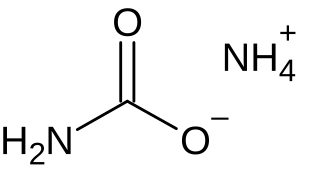

Ammonium carbamate is a chemical compound with the formula [NH4][H2NCO2] consisting of ammonium cation NH+4 and carbamate anion NH2COO−. It is a white solid that is extremely soluble in water, less so in alcohol. Ammonium carbamate can be formed by the reaction of ammonia NH3 with carbon dioxide CO2, and will slowly decompose to those gases at ordinary temperatures and pressures. It is an intermediate in the industrial synthesis of urea (NH2)2CO, an important fertilizer.

The Eberspächer Group of Companies is a privately owned international automotive supplier, headquartered in Esslingen am Neckar, Germany. Customers include almost all major manufacturers of passenger cars and commercial vehicles. It is one of the leading system developers and suppliers of exhaust technology, vehicle heaters and air-conditioning systems worldwide and is also involved in automotive electronics for electronic networking in the vehicles.

The Medium Diesel Engine (MDE) is a four-cylinder diesel engine developed by Adam Opel AG and branded "1.6 CDTI Ecotec" in most markets. Opel also adds the marketing term "Whisper Diesel" in some markets, claiming relatively low levels of noise, vibration, and harshness. Production commenced in late 2013 at Szentgotthárd, Hungary. The MDE is Opel's first all-aluminum diesel engine and offers a power density of 85 hp (63 kW) per liter 136 PS in its most powerful version. Maximum power and torque have been increased versus the previous-generation 1.7-liter engine, while fuel consumption has been reduced by up to 10 percent compared with a 2.0-liter CDTI engine of similar power output. This new 1.6 CDTI engine will replace the current 1.7-liter and lower-powered 2.0-liter diesel engines in a wide range of Opel models, with more- and less-powerful versions to come. The most powerful version of this engine, delivering 136 PS at 3,500–4,000 rpm and 320 N⋅m (236 lb⋅ft) at 2,000 rpm, was first introduced in the 2013 Opel Zafira Tourer, and later in the 2014 Opel Astra J and restyled 2014 Opel Meriva B. In 2014, versions were released with power outputs of 110 and 95 PS.

The EMD 1010 or EMD 265 is a line of four-stroke diesel engines manufactured by Electro-Motive Diesel. The precursor to the 1010 was introduced around 1998 as the 265H or H-Engine. The H-engine was initially designed for use as a 6,300 hp (4,700 kW) 16 cylinder, the EMD SD90MAC; however, the early engines were found to be unreliable, and unsuccessful in the market, with the proven EMD 710 2-stroke design being preferred. The EMD four-stroke engine was resurrected in 2015 to meet EPA Tier 4 emissions regulations.

Urine patches in cattle pastures generate large concentrations of the greenhouse gas nitrous oxide through nitrification and denitrification processes in urine-contaminated soils. Over the past few decades, the cattle population has increased more rapidly than the human population. Between the years 2000 and 2050, the cattle population is expected to increase from 1.5 billion to 2.6 billion. When large populations of cattle are packed into pastures, excessive amounts of urine soak into soils. This increases the rate at which nitrification and denitrification occur and produce nitrous oxide. Currently, nitrous oxide is one of the single most important ozone-depleting emissions and is expected to remain the largest throughout the 21st century.