Oil painting is the process of painting with pigments with a medium of drying oil as the binder. It has been the most common technique for artistic painting on canvas, wood panel or copper for several centuries, spreading from Europe to the rest of the world. The advantages of oil for painting images include "greater flexibility, richer and denser colour, the use of layers, and a wider range from light to dark". But the process is slower, especially when one layer of paint needs to be allowed to dry before another is applied.

Paint is a liquid pigment that, after application to a solid material, and allowed to dry, adds a film-like layer to protect, add color, or provide texture. Paint can be made in many colors—and in many different types. Most paints are either oil-based or water-based, and each has distinct characteristics.

A triglyceride is an ester derived from glycerol and three fatty acids. Triglycerides are the main constituents of body fat in humans and other vertebrates, as well as vegetable fat. They are also present in the blood to enable the bidirectional transference of adipose fat and blood glucose from the liver, and are a major component of human skin oils.

Varnish is a clear transparent hard protective coating or film. It is not to be confused with wood stain. It usually has a yellowish shade due to the manufacturing process and materials used, but it may also be pigmented as desired. It is sold commercially in various shades.

Lacquer is a type of hard and usually shiny coating or finish applied to materials such as wood or metal. It is most often made from resin extracted from trees and waxes and has been in use since antiquity.

Linseed oil, also known as flaxseed oil or flax oil, is a colourless to yellowish oil obtained from the dried, ripened seeds of the flax plant. The oil is obtained by pressing, sometimes followed by solvent extraction.

Oil paint is a type of slow-drying paint that consists of particles of pigment suspended in a drying oil, commonly linseed oil. The viscosity of the paint may be modified by the addition of a solvent such as turpentine or white spirit, and varnish may be added to increase the glossiness of the dried oil paint film. The addition of oil or alkyd medium can also be used to modify the viscosity and drying time of oil paint. Oil paints were first used in Asia as early as the 7th century AD and can be seen in examples of Buddhist paintings in Afghanistan. Oil-based paints made their way to Europe by the 12th century and were used for simple decoration, but oil painting did not begin to be adopted as an artistic medium there until the early 15th century. Common modern applications of oil paint are in finishing and protection of wood in buildings and exposed metal structures such as ships and bridges. Its hard-wearing properties and luminous colors make it desirable for both interior and exterior use on wood and metal. Due to its slow-drying properties, it has recently been used in paint-on-glass animation. The thickness of the coat has considerable bearing on the time required for drying: thin coats of oil paint dry relatively quickly.

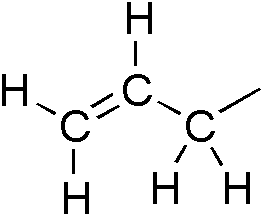

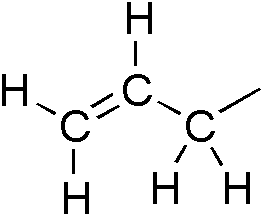

In organic chemistry, an allyl group is a substituent with the structural formula −CH2−HC=CH2. It consists of a methylene bridge attached to a vinyl group. The name is derived from the scientific name for garlic, Allium sativum. In 1844, Theodor Wertheim isolated an allyl derivative from garlic oil and named it "Schwefelallyl". The term allyl applies to many compounds related to H2C=CH−CH2, some of which are of practical or of everyday importance, for example, allyl chloride.

Water-miscible oil paint is oil paint either engineered or to which an emulsifier has been added, allowing it to be thinned and cleaned up with water. These paints make it possible to avoid using, or at least reduce volatile organic compounds such as turpentine that may be harmful if inhaled. Water-miscible oil paint can be mixed and applied using the same techniques as traditional oil-based paint, but while still wet it can be removed from brushes, palettes, and rags with ordinary soap and water. One of the ways its water solubility comes from is the use of an oil medium in which one end of the molecule has been engineered to be hydrophilic and thus bind loosely to water molecules, as in a solution. This type of paint is different to those that are engineered to enable cleaning of brushes and application equipment in water but are not in themselves water reducible.

In chemistry and biology a cross-link is a bond or a short sequence of bonds that links one polymer chain to another. These links may take the form of covalent bonds or ionic bonds and the polymers can be either synthetic polymers or natural polymers.

In chemistry, the iodine value is the mass of iodine in grams that is consumed by 100 grams of a chemical substance. Iodine numbers are often used to determine the degree of unsaturation in fats, oils and waxes. In fatty acids, unsaturation occurs mainly as double bonds which are very reactive towards halogens, the iodine in this case. Thus, the higher the iodine value, the more unsaturations are present in the fat. It can be seen from the table that coconut oil is very saturated, which means it is good for making soap. On the other hand, linseed oil is highly unsaturated, which makes it a drying oil, well suited for making oil paints.

Autoxidation refers to oxidations brought about by reactions with oxygen at normal temperatures, without the intervention of flame or electric spark. The term is usually used to describe the gradual degradation of organic compounds in air at ambient temperatures. Many common phenomena can be attributed to autoxidation, such as food going rancid, the 'drying' of varnishes and paints, and the perishing of rubber. It is also an important concept in both industrial chemistry and biology. Autoxidation is therefore a fairly broad term and can encompass examples of photooxygenation and catalytic oxidation.

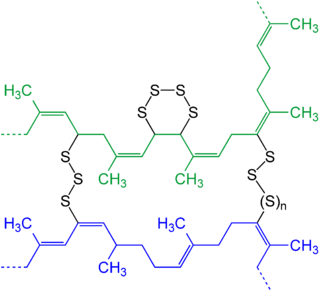

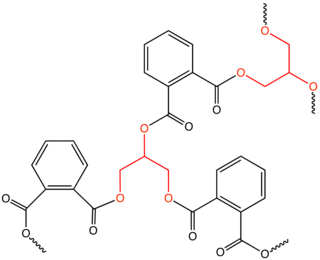

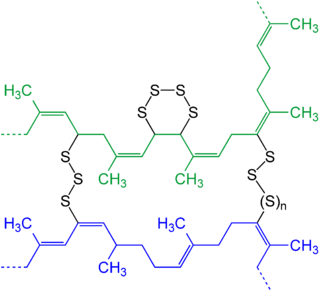

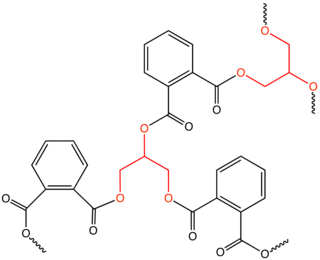

An alkyd is a polyester resin modified by the addition of fatty acids and other components. Alkyds are derived from polyols and organic acids including dicarboxylic acids or carboxylic acid anhydride and triglyceride oils. The term alkyd is a modification of the original name "alcid", reflecting the fact that they are derived from alcohol and organic acids. The inclusion of a fatty acid confers a tendency to form flexible coatings. Alkyds are used in paints, varnishes and in moulds for casting. They are the dominant resin or binder in most commercial oil-based coatings. Approximately 200,000 tons of alkyd resins are produced each year. The original alkyds were compounds of glycerol and phthalic acid sold under the name Glyptal. These were sold as substitutes for the darker-colored copal resins, thus creating alkyd varnishes that were much paler in colour. From these, the alkyds that are known today were developed.

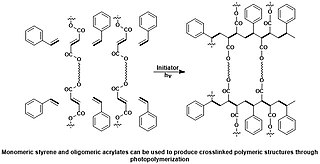

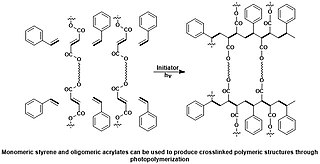

A photopolymer or light-activated resin is a polymer that changes its properties when exposed to light, often in the ultraviolet or visible region of the electromagnetic spectrum. These changes are often manifested structurally, for example hardening of the material occurs as a result of cross-linking when exposed to light. An example is shown below depicting a mixture of monomers, oligomers, and photoinitiators that conform into a hardened polymeric material through a process called curing.

Perilla oil is an edible vegetable oil derived from perilla seeds. Having a distinct nutty aroma and taste, the oil pressed from the toasted perilla seeds is used as a flavor enhancer, condiment, and cooking oil in Korean cuisine. The oil pressed from untoasted perilla seeds is used for non-culinary purposes.

Curing is a chemical process employed in polymer chemistry and process engineering that produces the toughening or hardening of a polymer material by cross-linking of polymer chains. Even if it is strongly associated with the production of thermosetting polymers, the term "curing" can be used for all the processes where a solid product is obtained from a liquid solution, such as with PVC plastisols.

Danish oil is a wood finishing oil, often made of tung oil or polymerized linseed oil. Because there is no defined formulation, its composition varies among manufacturers.

An oil drying agent, also known as siccative, is a coordination compound that accelerates (catalyzes) the hardening of drying oils, often as they are used in oil-based paints. This so-called "drying" occurs through free-radical chemical crosslinking of the oils. The catalysts promote this free-radical autoxidation of the oils with air.

Tung oil or China wood oil is a drying oil obtained by pressing the seed from the nut of the tung tree. Tung oil hardens upon exposure to air, and the resulting coating is transparent and has a deep, almost wet look. Used mostly for finishing and protecting wood, after numerous coats, the finish can even look plastic-like. Related drying oils include linseed, safflower, poppy, and soybean oils. Raw tung oil tends to dry to a fine, wrinkled finish ; this property was used to make wrinkle finishes, usually by adding excess cobalt drier. To prevent wrinkling, the oil is heated to gas-proof it.

Waterborne resins are sometimes called water-based resins. They are resins or polymeric resins that use water as the carrying medium as opposed to solvent or solvent-less. Resins are used in the production of coatings, adhesives, sealants, elastomers and composite materials. When the phrase waterborne resin is used, it usually describes all resins which have water as the main carrying solvent. The resin could be water-soluble, water reducible or water dispersed.