Lumber is wood that has been processed into dimensional lumber, including beams and planks or boards, a stage in the process of wood production. Lumber is mainly used for construction framing, as well as finishing. Lumber has many uses beyond home building. Lumber is sometimes referred to as timber as an archaic term and still in England, while in most parts of the world the term timber refers specifically to unprocessed wood fiber, such as cut logs or standing trees that have yet to be cut.

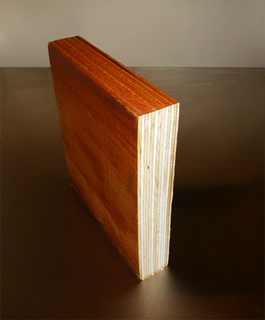

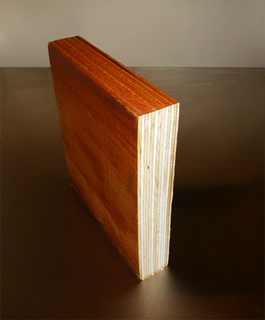

Plywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which include medium-density fibreboard (MDF), oriented strand board (OSB) and particle board (chipboard).

South Shore is a home rule-class city in Greenup County, Kentucky, United States. The population was 1,122 at the 2010 census, down from 1,226 in 2000. It is located along the Ohio River across from Portsmouth, Ohio, at the mouth of Tygarts Creek. South Shore is a part of the Huntington-Ashland, WV-KY-OH, Metropolitan Statistical Area (MSA).

The board foot or board-foot is a unit of measurement for the volume of lumber in the United States and Canada. It equals the volume of a one-foot (305 mm) length of a board, one foot wide and one inch (25.4 mm) thick.

Engineered wood, also called mass timber, composite wood, man-made wood, or manufactured board, includes a range of derivative wood products which are manufactured by binding or fixing the strands, particles, fibres, or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite material. The panels vary in size but can range upwards of 64 by 8 feet and in the case of cross-laminated timber (CLT) can be of any thickness from a few inches to 16 inches (410 mm) or more. These products are engineered to precise design specifications, which are tested to meet national or international standards and provide uniformity and predictability in their structural performance. Engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial products. The products can be used for joists and beams that replace steel in many building projects. The term mass timber describes a group of building materials that can replace concrete assemblies. Broad-base adoption of mass timber and their substitution for steel and concrete in new mid-rise construction projects over the coming decades could help mitigate climate change.

In woodworking, a rip-cut is a type of cut that severs or divides a piece of wood parallel to the grain. The other typical type of cut is a cross-cut, a cut perpendicular to the grain. Unlike cross-cutting, which shears the wood fibers, a rip saw works more like a series of chisels, lifting off small splinters of wood. The nature of the wood grain requires the shape of the saw teeth to be different thus the need for both rip saws and crosscut saws; however some circular saw blades are combination blades and can make both types of cuts. A rip cut is the fundamental type of cut made at a sawmill.

A sawmill or lumber mill is a facility where logs are cut into lumber. Modern sawmills use a motorized saw to cut logs lengthwise to make long pieces, and crosswise to length depending on standard or custom sizes. The "portable" sawmill is of simple operation. The log lies flat on a steel bed, and the motorized saw cuts the log horizontally along the length of the bed, by the operator manually pushing the saw. The most basic kind of sawmill consists of a chainsaw and a customized jig, with similar horizontal operation.

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives. It is typically used for headers, beams, rimboard, and edge-forming material. LVL offers several advantages over typical milled lumber: Made in a factory under controlled specifications, it is stronger, straighter, and more uniform. Due to its composite nature, it is much less likely than conventional lumber to warp, twist, bow, or shrink. LVL is a type of structural composite lumber, comparable to glued laminated timber (glulam) but with a higher allowable stress.

In woodworking, veneer refers to thin slices of wood and sometimes bark, usually thinner than 3 mm, that typically are glued onto core panels to produce flat panels such as doors, tops and panels for cabinets, parquet floors and parts of furniture. They are also used in marquetry. Plywood consists of three or more layers of veneer. Normally, each is glued with its grain at right angles to adjacent layers for strength. Veneer beading is a thin layer of decorative edging placed around objects, such as jewelry boxes. Veneer is also used to replace decorative papers in Wood Veneer HPL.

The Babcock Lumber Company was founded in Pittsburgh, Pennsylvania in 1887 and conducted logging operations in the eastern United States. In 1951 the company diversified into building material distribution. Today the company has two main divisions: hardwood lumber manufacturing and wholesale building material distribution.

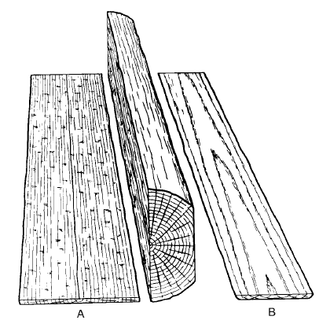

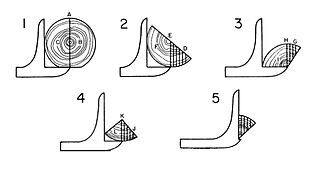

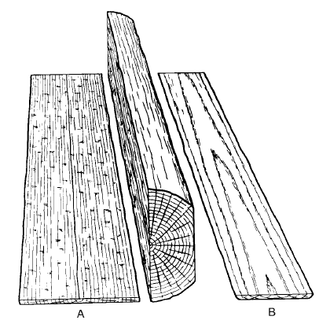

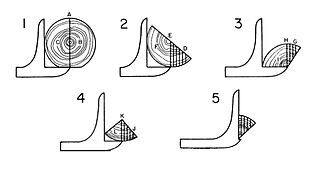

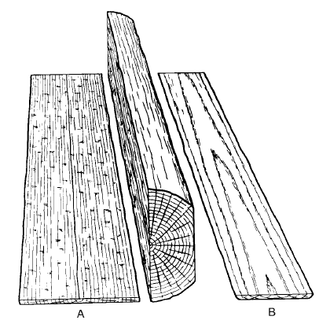

Quarter sawing or quartersawing is a woodworking process that produces quarter sawn or quarter-cut boards in the rip cutting of logs into lumber. The resulting lumber can also be called radially-sawn or simply quartered. There is widespread confusion between the terms rift sawn and quarter sawn with the terms defined both with opposite meanings and as synonyms.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

Wood flooring is any product manufactured from timber that is designed for use as flooring, either structural or aesthetic. Wood is a common choice as a flooring material and can come in various styles, colors, cuts, and species. Bamboo flooring is often considered a form of wood flooring, although it is made from bamboo rather than timber.

The Meadow River Lumber Company, which operated in Rainelle, West Virginia from 1906 to 1975, was the largest hardwood sawmill in the world. It had three 9 feet (2.7 m) bandsaws under one roof. In 1928, during peak production, its 500 employees produced 31 million board feet of lumber, cutting 3,000 acres (12 km2) of virgin timber a year.

Reclaimed lumber is processed wood retrieved from its original application for purposes of subsequent use. Most reclaimed lumber comes from timbers and decking rescued from old barns, factories and warehouses, although some companies use wood from less traditional structures such as boxcars, coal mines and wine barrels. Reclaimed or antique lumber is used primarily for decoration and home building, for example for siding, architectural details, cabinetry, furniture and flooring.

Rift-sawing is a woodworking process that aims to produce lumber that is less vulnerable to distortion than flat sawn lumber. Rift-sawing may be done strictly along a log's radials—perpendicular to the annular growth ring orientation or wood grain—or as part of the quarter sawing process.

LL Flooring is an American retailer of hard-surface flooring including hardwood flooring, laminate flooring, vinyl plank flooring, tile flooring, bamboo flooring and cork flooring, as well as flooring tools and accessories.

Baird Brothers Fine Hardwoods is a privately held manufacturer and retailer of interior hardwood products. It has been family owned and operated since 1960. The company is headquartered in Canfield, Ohio.

A swingblade sawmill utilizes a single circular sawblade which pivots about a 90 degree point, to saw in both vertical and horizontal planes. The single blade travels horizontally in one direction down the log, and returns in vertical position, thus removing a sawn piece of timber. The swingblade head unit is normally mounted on a moving frame that travels along a track or tracks, up and down a stationary log.

Flat sawing, flitch sawing or plain sawing is a woodworking process that produces flat cut or plain cut boards of lumber.