The MacPherson strut is a type of automotive suspension system that uses the top of a telescopic damper as the upper steering pivot. It is widely used in the front suspension of modern vehicles. The name comes from American automotive engineer Earle S. MacPherson, who invented and developed the design.

A strut is a structural component commonly found in engineering, aeronautics, architecture and anatomy. Struts generally work by resisting longitudinal compression, but they may also serve in tension.

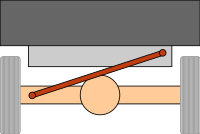

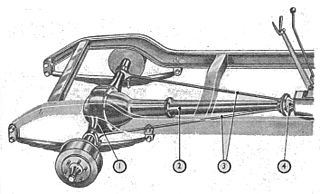

A torsion bar suspension, also known as a torsion spring suspension, is any vehicle suspension that uses a torsion bar as its main weight-bearing spring. One end of a long metal bar is attached firmly to the vehicle chassis; the opposite end terminates in a lever, the torsion key, mounted perpendicular to the bar, that is attached to a suspension arm, a spindle, or the axle. Vertical motion of the wheel causes the bar to twist around its axis and is resisted by the bar's torsion resistance. The effective spring rate of the bar is determined by its length, cross section, shape, material, and manufacturing process.

A multi-link suspension is a type of vehicle suspension with one or more transversal arms. A wider definition can consider any independent suspensions having three control links or more multi-link suspensions. These arms do not have to be of equal length, and may be angled away from their "obvious" direction. It was first introduced in the late 1960s on the Mercedes-Benz C111 and later on their W201 and W124 series.

Suspension is the system of tires, tire air, springs, shock absorbers and linkages that connects a vehicle to its wheels and allows relative motion between the two. Suspension systems must support both road holding/handling and ride quality, which are at odds with each other. The tuning of suspensions involves finding the right compromise. It is important for the suspension to keep the road wheel in contact with the road surface as much as possible, because all the road or ground forces acting on the vehicle do so through the contact patches of the tires. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear. The design of front and rear suspension of a car may be different.

A leaf spring is a simple form of spring commonly used for suspension in wheeled vehicles. Originally called a laminated or carriage spring, and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, it is one of the oldest forms of vehicle suspension. A leaf spring is one or more narrow, arc-shaped, thin plates that are attached to the axle and chassis in a way that allows the leaf spring to flex vertically in response to irregularities in the road surface. Lateral leaf springs are the most commonly used arrangement, running the length of the vehicle and mounted perpendicular to the wheel axle, but numerous examples of transverse leaf springs exist as well.

Independent suspension is any automobile suspension system that allows each wheel on the same axle to move vertically independently of the others. This is contrasted with a beam axle or deDion axle system in which the wheels are linked. "Independent" refers to the motion or path of movement of the wheels or suspension. It is common for the left and right sides of the suspension to be connected with anti-roll bars or other such mechanisms. The anti-roll bar ties the left and right suspension spring rates together but does not tie their motion together.

A double wishbone suspension is an independent suspension design for automobiles using two wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the chassis and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to control vertical movement. Double wishbone designs allow the engineer to carefully control the motion of the wheel throughout suspension travel, controlling such parameters as camber angle, caster angle, toe pattern, roll center height, scrub radius, scuff, and more.

A trailing-arm suspension, also referred to as trailing-link, is a form of vehicle suspension. In a motor vehicle it places one or more horizontal arms perpendicular to and forward of the axle on the chassis or unibody, which are connected to the axle or wheels with pivot joint(s). These are typically used on the rear axle or wheels of vehicles, but also found in both front and main landing gear of aircraft.

The Chapman strut is a design of independent rear suspension used for light cars, particularly sports and racing cars. It takes its name from, and is best known for its use by, Colin Chapman of Lotus.

A de Dion tube is a form of non-independent automobile suspension. It is a considerable improvement over the swing axle, Hotchkiss drive, or live axle. Because it plays no part in transmitting power to the drive wheels, it is sometimes called a "dead axle".

In kinematics, Watt's linkage is a type of mechanical linkage invented by James Watt in which the central moving point of the linkage is constrained to travel on a nearly straight line. It was described in Watt's patent specification of 1784 for the Watt steam engine.

An anti-roll bar is an automobile suspension part that helps reduce the body roll of a vehicle during fast cornering or over road irregularities. It links opposite front or rear wheels to a torsion spring using short lever arms for anchors. This increases the suspension's roll stiffness—its resistance to roll in turns.

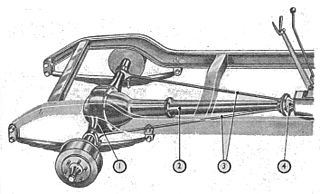

The Hotchkiss drive is a shaft drive form of power transmission. It was the dominant means for front-engine, rear-wheel drive layout cars in the 20th century. The name comes from the French automobile manufacturer Hotchkiss, although other makers, such as Peerless, used similar systems before Hotchkiss.

A torque tube system is a power transmission and braking technology that involves a stationary housing around the drive shaft, often used in automobiles with a front engine and rear drive. The torque tube consists of a large diameter stationary housing between the transmission and rear end that fully encloses a rotating tubular steel or small-diameter solid drive shaft that transmits the power of the engine to a regular or limited-slip differential. The purpose of a torque tube is to hold the rear end in place during acceleration and braking. Otherwise, the axle housing would suffer axle wrap, such that the front of the differential would lift up excessively during acceleration and sink down during braking. Its use is not as widespread in modern automobiles as is the Hotchkiss drive, which holds the rear end in place and prevents it from flipping up or down, during acceleration and braking, by anchoring the axle housings to the leaf springs using spring perches.

Air suspension is a type of vehicle suspension powered by an electric or engine-driven air pump or compressor. This compressor pumps the air into a flexible bellows, usually made from textile-reinforced rubber. Unlike hydropneumatic suspension, which offers many similar features, air suspension does not use pressurized liquid, but pressurized air. The air pressure inflates the bellows, and raises the chassis from the axle.

A beam axle, rigid axle or solid axle is a dependent suspension design in which a set of wheels is connected laterally by a single beam or shaft. Beam axles were once commonly used at the rear wheels of a vehicle, but historically they have also been used as front axles in four-wheel-drive vehicles. In most automobiles, beam axles have been replaced with front and rear independent suspensions.

The twist-beam rear suspension is a type of automobile suspension based on a large H or C-shaped member. The front of the H attaches to the body via rubber bushings, and the rear of the H carries each stub-axle assembly, on each side of the car. The cross beam of the H holds the two trailing arms together, and provides the roll stiffness of the suspension, by twisting as the two trailing arms move vertically, relative to each other.

The Rally Fighter is an American automobile manufactured by Local Motors and introduced in 2009. It is the first car to be developed using co-creation design. The exterior design was submitted by Sangho Kim and selected through community votes. The Rally Fighter is street legal in all 50 US states.

Clément-Panhard is an automobile designed in 1898 by Arthur Constantin Krebs, manager of Panhard & Levassor co, from his 1896 patent of a car fitted with an electromagnetic gearbox, whose licence was acquired by Émile Levassor.