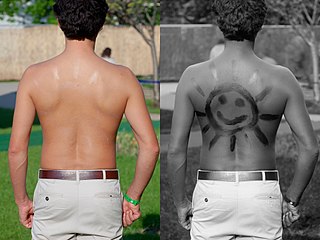

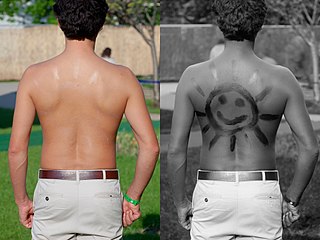

Ultraviolet (UV) is a form of electromagnetic radiation with wavelength shorter than that of visible light, but longer than X-rays. UV radiation is present in sunlight, and constitutes about 10% of the total electromagnetic radiation output from the Sun. It is also produced by electric arcs; Cherenkov radiation; and specialized lights, such as mercury-vapor lamps, tanning lamps, and black lights.

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns.

Velvet is a type of woven tufted fabric in which the cut threads are evenly distributed, with a short, dense pile, giving it a distinctive soft feel. By extension, the word velvety means "smooth like velvet". In the past, velvet was typically made from silk. Today, velvet can be made from linen, cotton, wool and synthetic fibers.

Sunscreen, also known as sunblock or sun cream, is a photoprotective topical product for the skin that helps protect against sunburn and most importantly prevent skin cancer. Sunscreens come as lotions, sprays, gels, foams, sticks, powders and other topical products. Sunscreens are common supplements to clothing, particularly sunglasses, sunhats and special sun protective clothing, and other forms of photoprotection.

Lyocell is a semi-synthetic fiber used to make textiles for clothing and other purposes. It is a form of regenerated cellulose made by dissolving pulp and dry jet-wet spinning. Unlike rayon made by some of the more common viscose processes, Lyocell production does not use carbon disulfide, which is toxic to workers and the environment. Lyocell was originally trademarked as Tencel in 1982.

Sun tanning or tanning is the process whereby skin color is darkened or tanned. It is most often a result of exposure to ultraviolet (UV) radiation from sunlight or from artificial sources, such as a tanning lamp found in indoor tanning beds. People who deliberately tan their skin by exposure to the sun engage in a passive recreational activity of sun bathing. Some people use chemical products which can produce a tanning effect without exposure to ultraviolet radiation, known as sunless tanning.

A rash guard, also known as rash vest or rashie, is an athletic shirt made of spandex and nylon or polyester. The name rash guard reflects the fact that the shirt protects the wearer against rashes caused by abrasion, or by sunburn from extended exposure to the sun, as sun protective clothing.

Coolmax is the brand name for a series of polyester fabrics developed and marketed by The Lycra Company.

The ultraviolet index, or UV index, is an international standard measurement of the strength of the sunburn-producing ultraviolet (UV) radiation at a particular place and time. It is primarily used in daily and hourly forecasts aimed at the general public. The UV index is designed as an open-ended linear scale, directly proportional to the intensity of UV radiation, and adjusting for wavelength based on what causes human skin to sunburn. The purpose of the UV index is to help people effectively protect themselves from UV radiation, which has health benefits in moderation but in excess causes sunburn, skin aging, DNA damage, skin cancer, immunosuppression, and eye damage, such as cataracts.

Sailcloth is cloth used to make sails. It can be made of a variety of materials, including natural fibers such as flax, hemp, or cotton in various forms of sail canvas, and synthetic fibers such as nylon, polyester, aramids, and carbon fibers in various woven, spun, and molded textiles.

AATCC—the American Association of Textile Chemists and Colorists— is a 501(c)(6) not-for-profit professional association that provides test method development, quality control materials, educational development, and networking for textile and apparel professionals throughout the world.

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

Naturally colored cotton is cotton that has been bred to have colors other than the yellowish off-white typical of modern commercial cotton fibres. Colors grown include red, green and several shades of brown. The cotton's natural color does not fade. Yields are typically lower and the fiber is shorter and weaker but has a softer feel than the more commonly available "white" cotton.

Sunburn is a form of radiation burn that affects living tissue, such as skin, that results from an overexposure to ultraviolet (UV) radiation, usually from the Sun. Common symptoms in humans and other animals include red or reddish skin that is hot to the touch or painful, general fatigue, and mild dizziness. Other symptoms include blistering, peeling skin, swelling, itching, and nausea. Excessive UV radiation is the leading cause of (primarily) non-malignant skin tumors, which in extreme cases can be life-threatening. Sunburn is an inflammatory response in the tissue triggered by direct DNA damage by UV radiation. When the cells' DNA is overly damaged by UV radiation, type I cell-death is triggered and the tissue is replaced.

Many materials have been used to make garments throughout history. Grasses, furs and much more complex and exotic materials have been used. Cultures like the Arctic Circle, make their wardrobes out of prepared and decorated furs and skins.[1] Different cultures have added cloth to leather and skins as a way to replace real leather. A wide range of fibers, including natural, cellulose, and synthetic fibers, can be used to weave or knit cloth.

Dimensional stability pertains to a fabric's ability to maintain its initial size and shape even after undergoing wear and care, which is a desirable property. Dimension stability in fabrics or Shrinkage is the change of dimensions in textile products when they are washed or relaxed. The change is always expressed relative to the dimensions before the exposure of washing or relaxing. Shrinkage is also called residual shrinkage and measured in percentage. The major cause of shrinkages is the release of stresses and strains introduced in manufacturing processes. Textile manufacturing is based on the conversion of fiber into yarn, yarn into fabric, includes spinning, weaving, or knitting, etc. The fabric passes through many inevitable changes and mechanical forces during this journey. When the products are immersed in water, the water acts as a relaxing medium, and all stresses and strains are relaxed and the fabric tries to come back to its original state.

Textile performance, also known as fitness for purpose, is a textile's capacity to withstand various conditions, environments, and hazards, qualifying it for particular uses. The performance of textile products influences their appearance, comfort, durability, and protection. Different textile applications require a different set of performance parameters. As a result, the specifications determine the level of performance of a textile product. Textile testing certifies the product's conformity to buying specification. It describes product manufactured for non-aesthetic purposes, where fitness for purpose is the primary criterion. Engineering of high-performance fabrics presents a unique set of challenges.

Barré is an unintentional repetitive horizontal pattern in fabrics that is generally undesirable and considered as a defect. It appears as a lateral stripe pattern. Barré occurs for many reasons associated with the manufacturing of textile ensembles like fiber, yarn, fabric manufacturing, weaving or knitting, or finishing faults.

Textile testing is the process of measuring the properties and performance of textile materials—textile testing includes physical and chemical testing of raw materials to finished products.