Photoconductivity is an optical and electrical phenomenon in which a material becomes more electrically conductive due to the absorption of electromagnetic radiation such as visible light, ultraviolet light, infrared light, or gamma radiation.

Titanium dioxide, also known as titanium(IV) oxide or titania, is the inorganic compound with the chemical formula TiO

2. When used as a pigment, it is called titanium white, Pigment White 6 (PW6), or CI 77891. It is a white solid that is insoluble in water, although mineral forms can appear black. As a pigment, it has a wide range of applications, including paint, sunscreen, and food coloring. When used as a food coloring, it has E number E171. World production in 2014 exceeded 9 million tonnes. It has been estimated that titanium dioxide is used in two-thirds of all pigments, and pigments based on the oxide have been valued at a price of $13.2 billion.

Indium tin oxide (ITO) is a ternary composition of indium, tin and oxygen in varying proportions. Depending on the oxygen content, it can be described as either a ceramic or an alloy. Indium tin oxide is typically encountered as an oxygen-saturated composition with a formulation of 74% In, 8% Sn, and 18% O by weight. Oxygen-saturated compositions are so typical that unsaturated compositions are termed oxygen-deficient ITO. It is transparent and colorless in thin layers, while in bulk form it is yellowish to gray. In the infrared region of the spectrum it acts as a metal-like mirror.

A nanoparticle or ultrafine particle is a particle of matter 1 to 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 100 nm in only two directions. At the lowest range, metal particles smaller than 1 nm are usually called atom clusters instead.

Magnetic semiconductors are semiconductor materials that exhibit both ferromagnetism and useful semiconductor properties. If implemented in devices, these materials could provide a new type of control of conduction. Whereas traditional electronics are based on control of charge carriers, practical magnetic semiconductors would also allow control of quantum spin state. This would theoretically provide near-total spin polarization, which is an important property for spintronics applications, e.g. spin transistors.

In chemistry, photocatalysis is the acceleration of a photoreaction in the presence of a photocatalyst, the excited state of which "repeatedly interacts with the reaction partners forming reaction intermediates and regenerates itself after each cycle of such interactions." In many cases, the catalyst is a solid that upon irradiation with UV- or visible light generates electron–hole pairs that generate free radicals. Photocatalysts belong to three main groups; heterogeneous, homogeneous, and plasmonic antenna-reactor catalysts. The use of each catalysts depends on the preferred application and required catalysis reaction.

In nanotechnology, nanorods are one morphology of nanoscale objects. Each of their dimensions range from 1–100 nm. They may be synthesized from metals or semiconducting materials. Standard aspect ratios are 3-5. Nanorods are produced by direct chemical synthesis. A combination of ligands act as shape control agents and bond to different facets of the nanorod with different strengths. This allows different faces of the nanorod to grow at different rates, producing an elongated object.

Cobalt green is an ambiguous term for either of two families of green inorganic pigments. Both are obtained by doping cobalt(II) oxide into colorless host oxides.

A zinc oxide nanorod sensor or ZnO nanorod sensor is an electronic or optical device detecting presence of certain gas or liquid molecules in the ambient atmosphere. The sensor exploits enhanced surface area intrinsic to all nano-sized materials, including ZnO nanorods. Adsorption of molecules on the nanorods can be detected through variation of the nanorods' properties, such as photoluminescence, electrical conductivity, vibration frequency, mass, etc. The simplest and thus most popular way is to pass electrical current through the nanorods and observe its changes upon exposure to gas. Synthesis can be obtained by a hydrothermal method using 1:1 Molar solution of hexamine and Zinc nitrate solution kept together for 56 hours in an autoclave at 60-70 degree Celsius.

Transparent conducting films (TCFs) are thin films of optically transparent and electrically conductive material. They are an important component in a number of electronic devices including liquid-crystal displays, OLEDs, touchscreens and photovoltaics. While indium tin oxide (ITO) is the most widely used, alternatives include wider-spectrum transparent conductive oxides (TCOs), conductive polymers, metal grids and random metallic networks, carbon nanotubes (CNT), graphene, nanowire meshes and ultra thin metal films.

The Center of Excellence (CoE) in Nanotechnology is located at the Asian Institute of Technology campus. It is one of the eight centers of excellence in Thailand.

Zinc ferrites are a series of synthetic inorganic compounds of zinc and iron (ferrite) with the general formula of ZnxFe3−xO4. Zinc ferrite compounds can be prepared by aging solutions of Zn(NO3)2, Fe(NO3)3, and triethanolamine in the presence and in the absence of hydrazine, or reacting iron oxides and zinc oxide at high temperature. Spinel (Zn, Fe) Fe2O4 appears as a tan-colored solid that is insoluble in water, acids, or diluted alkali. Because of their high opacity, zinc ferrites can be used as pigments, especially in applications requiring heat stability. For example, zinc ferrite prepared from yellow iron oxide can be used as a substitute for applications in temperatures above 350 °F (177 °C). When added to high corrosion-resistant coatings, the corrosion protection increases with an increase in the concentration of zinc ferrite.

Carbon nanotube supported catalyst is a novel supported catalyst, using carbon nanotubes as the support instead of the conventional alumina or silicon support. The exceptional physical properties of carbon nanotubes (CNTs) such as large specific surface areas, excellent electron conductivity incorporated with the good chemical inertness, and relatively high oxidation stability makes it a promising support material for heterogeneous catalysis.

Most of the synthesized Zinc oxide (ZnO) nanostructures in different geometric configurations such as nanowires, nanorods, nanobelts and nanosheets are usually in the wurtzite crystal structure. However, it was found from density functional theory calculations that for ultra-thin films of ZnO, the graphite-like structure was energetically more favourable as compared to the wurtzite structure. The stability of this phase transformation of wurtzite lattice to graphite-like structure of the ZnO film is only limited to the thickness of about several Zn-O layers and was subsequently verified by experiment. Similar phase transition was also observed in ZnO nanowire when it was subjected to uniaxial tensile loading. However, with the use of the first-principles all electron full-potential method, it was observed that the wurtzite to graphite-like phase transformation for ultra-thin ZnO films will not occur in the presence of a significant amount of oxygen vacancies (Vo) at the Zn-terminated (0001) surface of the thin film. The absence of the structural phase transformation was explained in terms of the Coulomb attraction at the surfaces. The graphitic ZnO thin films are structurally similar to the multilayer of graphite and are expected to have interesting mechanical and electronic properties for potential nanoscale applications. In addition, density functional theory calculations and experimental observations also indicate that the concentration of the Vo is the highest near the surfaces as compared to the inner parts of the nanostructures. This is due to the lower Vo defect formation energies in the interior of the nanostructures as compared to their surfaces.

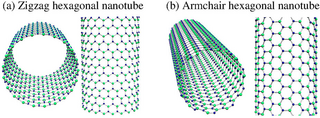

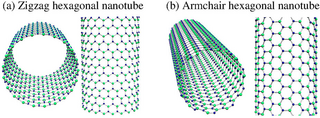

Gallium nitride nanotubes (GaNNTs) are nanotubes of gallium nitride. They can be grown by chemical vapour deposition.

Silicon nanowires, also referred to as SiNWs, are a type of semiconductor nanowire most often formed from a silicon precursor by etching of a solid or through catalyzed growth from a vapor or liquid phase. Such nanowires have promising applications in lithium ion batteries, thermoelectrics and sensors. Initial synthesis of SiNWs is often accompanied by thermal oxidation steps to yield structures of accurately tailored size and morphology.

Praseodymium(III,IV) oxide is the inorganic compound with the formula Pr6O11 that is insoluble in water. It has a cubic fluorite structure. It is the most stable form of praseodymium oxide at ambient temperature and pressure.

Zinc oxide nanoparticles are nanoparticles of zinc oxide (ZnO) that have diameters less than 100 nanometers. They have a large surface area relative to their size and high catalytic activity. The exact physical and chemical properties of zinc oxide nanoparticles depend on the different ways they are synthesized. Some possible ways to produce ZnO nano-particles are laser ablation, hydrothermal methods, electrochemical depositions, sol–gel method, chemical vapor deposition, thermal decomposition, combustion methods, ultrasound, microwave-assisted combustion method, two-step mechanochemical–thermal synthesis, anodization, co-precipitation, electrophoretic deposition, and precipitation processes using solution concentration, pH, and washing medium. ZnO is a wide-bandgap semiconductor with an energy gap of 3.37 eV at room temperature.

Zinc oxide (ZnO) nanostructures are structures with at least one dimension on the nanometre scale, composed predominantly of zinc oxide. They may be combined with other composite substances to change the chemistry, structure or function of the nanostructures in order to be used in various technologies. Many different nanostructures can be synthesised from ZnO using relatively inexpensive and simple procedures. ZnO is a semiconductor material with a wide band gap energy of 3.3eV and has the potential to be widely used on the nanoscale. ZnO nanostructures have found uses in environmental, technological and biomedical purposes including ultrafast optical functions, dye-sensitised solar cells, lithium-ion batteries, biosensors, nanolasers and supercapacitors. Research is ongoing to synthesise more productive and successful nanostructures from ZnO and other composites. ZnO nanostructures is a rapidly growing research field, with over 5000 papers published during 2014-2019.

Nanomaterials are materials with a size ranging from 1 to 100 nm in at least one dimension. At the nanoscale, material properties become different. These unique properties can be exploited for a variety of applications, including the use of nanoparticles in skincare and cosmetics products.