A sextant is a doubly reflecting navigation instrument that measures the angular distance between two visible objects. The primary use of a sextant is to measure the angle between an astronomical object and the horizon for the purposes of celestial navigation.

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw widely used for accurate measurement of components in mechanical engineering and machining as well as most mechanical trades, along with other metrological instruments such as dial, vernier, and digital calipers. Micrometers are usually, but not always, in the form of calipers. The spindle is a very accurately machined screw and the object to be measured is placed between the spindle and the anvil. The spindle is moved by turning the ratchet knob or thimble until the object to be measured is lightly touched by both the spindle and the anvil.

In musical instrument classification, string instruments or chordophones, are musical instruments that produce sound from vibrating strings when a performer plays or sounds the strings in some manner.

A view camera is a large-format camera in which the lens forms an inverted image on a ground-glass screen directly at the film plane. The image is viewed, composed, and focused, then the glass screen is replaced with the film to expose exactly the same image seen on the screen.

Joinery is a part of woodworking that involves joining pieces of wood, engineered lumber, or synthetic substitutes, to produce more complex items. Some woodworking joints employ mechanical fasteners, bindings, or adhesives, while others use only wood elements.

A straightedge or straight edge is a tool used for drawing straight lines, or checking their straightness. If it has equally spaced markings along its length, it is usually called a ruler.

A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

In machining, a shaper is a type of machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is analogous to that of a lathe, except that it is (archetypally) linear instead of helical.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The drive mechanism is mounted below a table that provides support for the material, usually wood, being cut, with the blade protruding up through the table into the material.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

Caliper(s) or calliper(s) are an instrument used to measure the dimensions of an object; namely, the diameter or depth of a hole. The word caliper comes from latin roots meaning precise pincer.

A machinist square or engineer's square is the metalworkers' equivalent of a try square. It consists of a steel blade inserted and either welded or pinned into a heavier body at an angle of 90°. Usually a small notch is present at the inside corner of the square. This prevents small particles from accumulating at the juncture and affecting the square's reading.

A jointer or in some configurations, a jointer-planer is a woodworking machine used to produce a flat surface along a board's length. As a jointer, the machine operates on the narrow edge of boards, preparing them for use as butt joint or gluing into panels. A planer-jointer setup has the width that enables smoothing ('surface planing') and leveling the faces (widths) of boards small enough to fit the tables.

A wiggler, also known as a wobbler, edge-finder, center-finder or laser-centering-device, is a tool used with a machine like a mill, to accurately align the machine head with the work prior to machining.

A thickness planer is a woodworking machine to trim boards to a consistent thickness throughout their length. This machine transcribes the desired thickness using the downside as a reference / index. So, to produce a completely straight planed board requires that the down surface is straight before planing. Obtaining the first flat side requires either face planing with a jointer or face planing using a planer and jointer sled.

An ice hockey stick is a piece of equipment used in ice hockey to shoot, pass, and carry the puck across the ice. Ice hockey sticks are approximately 150–200 cm long, composed of a long, slender shaft with a flat extension at one end called the blade. National Hockey League (NHL) sticks are up to 63 inches long. The blade is the part of the stick used to contact the puck, and is typically 25 to 40 cm long. Stick dimensions can vary widely, as they are usually built to suit a particular player's size and preference. The blade is positioned at roughly a 135° angle from the axis of the shaft, giving the stick a partly 'L-shaped' appearance. The shaft of the stick is fairly rigid, but is slightly elastic to improve shot performance.

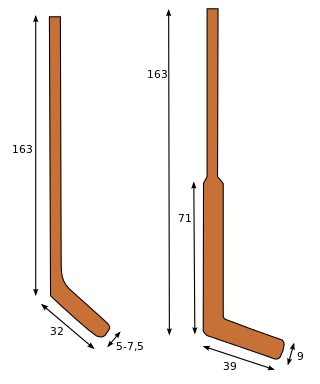

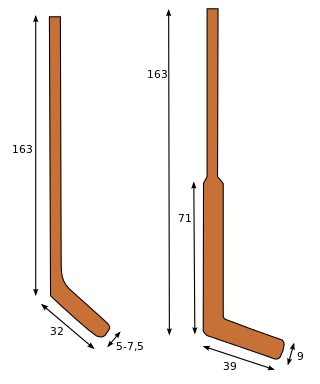

In field hockey, each player carries a stick and cannot take part in the game without it. The stick for an adult is usually in the range 89–95 cm (35–38 in) long. A maximum length of 105 cm (41.3") was stipulated from 2015. The maximum permitted weight is 737 grams. The majority of players use a stick in the range 19 oz to 22 oz. Traditionally hockey sticks were made of hickory, ash or mulberry wood with the head of the sticks being hand carved and therefore required skilled craftsmen to produce. Sticks made of wood continue to be made but the higher grade sticks are now manufactured from composite materials which were first permitted after 1992. These sticks usually contain a combination of fibreglass, aramid fiber and carbon fibre in varying proportions according to the characteristics required.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

A diameter tape (D-tape) is a measuring tape used to estimate the diameter of a cylinder object, typically the stem of a tree or pipe. A diameter tape has either metric or imperial measurements reduced by the value of π. This means the tape measures the diameter of the object. It is assumed that the cylinder object is a perfect circle. The diameter tape provides an approximation of diameter; most commonly used in dendrometry.