Paul (Louis-Toussaint) Héroult was a French scientist. He was one of the inventors of the Hall-Héroult process for smelting aluminium, and developed the first successful commercial electric arc furnace. He lived in Thury-Harcourt, Normandy.

The Hall–Héroult process is the major industrial process for smelting aluminium. It involves dissolving aluminium oxide (alumina) in molten cryolite, and electrolyzing the molten salt bath, typically in a purpose-built cell. The Hall–Héroult process applied at industrial scale happens at 940–980 °C and produces 99.5–99.8% pure aluminium. Recycled aluminum requires no electrolysis, thus it does not end up in this process.

Alcoa Corporation is a Pittsburgh-based industrial corporation. It is the world's eighth-largest producer of aluminum. Alcoa conducts operations in 10 countries. Alcoa is a major producer of primary aluminum, fabricated aluminum, and alumina combined, through its active and growing participation in all major aspects of the industry: technology, mining, refining, smelting, fabricating, and recycling.

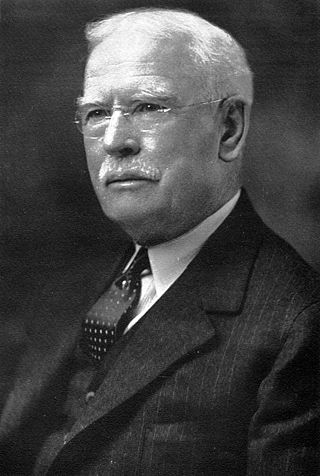

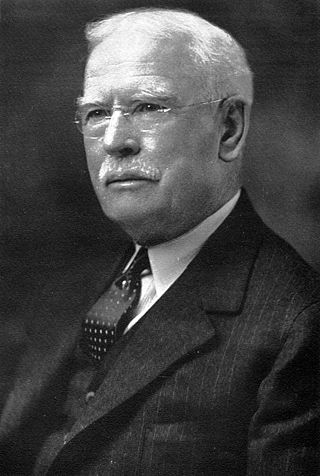

Charles Martin Hall was an American inventor, businessman, and chemist. He is best known for his invention in 1886 of an inexpensive method for producing aluminum, which became the first metal to attain widespread use since the prehistoric discovery of iron. He was one of the founders of Alcoa, along with Alfred E. Hunt; Hunt's partner at the Pittsburgh Testing Laboratory, George Hubbard Clapp; Hunt's chief chemist, W. S. Sample; Howard Lash, head of the Carbon Steel Company; Millard Hunsiker, sales manager for the Carbon Steel Company; and Robert Scott, a mill superintendent for the Carnegie Steel Company. Together they raised $20,000 to launch the Pittsburgh Reduction Company, which was later renamed Aluminum Company of America and shortened to Alcoa.

Materials science has shaped the development of civilizations since the dawn of mankind. Better materials for tools and weapons has allowed mankind to spread and conquer, and advancements in material processing like steel and aluminum production continue to impact society today. Historians have regarded materials as such an important aspect of civilizations such that entire periods of time have defined by the predominant material used. For most of recorded history, control of materials had been through alchemy or empirical means at best. The study and development of chemistry and physics assisted the study of materials, and eventually the interdisciplinary study of materials science emerged from the fusion of these studies. The history of materials science is the study of how different materials were used and developed through the history of Earth and how those materials affected the culture of the peoples of the Earth. The term "Silicon Age" is sometimes used to refer to the modern period of history during the late 20th to early 21st centuries.

Carl Josef Bayer was an chemist from Austria-Hungary who invented the Bayer process of extracting alumina from bauxite, essential to this day to the economical production of aluminium.

Kaiser Aluminum Corporation is an American aluminum producer. It is a spinoff from Kaiser Aluminum and Chemicals Corporation, which came to be when common stock was offered in Permanente Metals Corporation and Permanente Metals Corporation's name was changed to Kaiser Aluminum and Chemicals Corporation.

Alfred Hunt may refer to:

Aluminium recycling is the process in which secondary aluminium is created from scrap or other forms of end-of-life or otherwise unusable aluminium. It involves re-melting the metal, which is cheaper and more energy-efficient than the production of aluminum from raw bauxite via electrolysis of aluminum oxide (Al2O3) during the Hall–Héroult and Bayer processes.

A piano with an aluminum piano plate, called the Alumatone plate, was announced in 1945 by Winter and Company, piano manufacturers, and Alcoa, a manufacturer of aluminum and aluminum products. The metal frame of a piano, often called the plate or harp, anchors both ends of the strings, withstanding a tension of 20 tons or more. The first completely metal frames were patented in the mid-1820s, and they are now generally cast in iron.

George Hubbard Clapp (1858–1949) was an American pioneer in the aluminum industry and also a numismatist.

George Hubbard Clapp Hall is a contributing property to the Schenley Farms National Historic District on the campus of the University of Pittsburgh in the Oakland section of Pittsburgh, Pennsylvania. The six-story Gothic Revival structure, designed by Trautwein & Howard, was completed in 1956 and serves as the primary facility of the University of Pittsburgh Department of Biological Sciences. It contains laboratories, classrooms, a greenhouse, and an amphitheater-style lecture hall with 404 seats.

Arthur Vining Davis was an American industrialist and philanthropist, for many years president, chairman and largest stockholder of the aluminum producer Alcoa.

Aluminium smelting is the process of extracting aluminium from its oxide, alumina, generally by the Hall-Héroult process. Alumina is extracted from the ore bauxite by means of the Bayer process at an alumina refinery.

The Electric Smelting and Aluminum Company, founded as Cowles Electric Smelting and Aluminum Company, and Cowles Syndicate Company, Limited, formed in the United States and England during the mid-1880s to extract and supply valuable metals. Founded by two brothers from Ohio, the Cowles companies are remembered for producing alloys in quantity sufficient for commerce. Their furnaces were electric arc smelters, one of the first viable methods for extracting metals.

WearEver Cookware can trace its origins back to 1888 when Charles Martin Hall, a young inventor from Oberlin, Ohio discovered an inexpensive way to smelt aluminum by perfecting the electrochemical reduction process that extracted aluminum from bauxite ore. Seeking to fund his continued exploration of this new process Hall eventually partnered with Alfred E. Hunt, a metallurgist in charge of the Pittsburgh Testing Laboratory, raising $20,000 with the help of investors and eventually forming the Pittsburgh Reduction Company which would later come to be known as the Aluminum Company of America (ALCOA).

The Hoopes process is a metallurgical process, used to obtain the aluminium metal of very high purity(about 99.9% pure). The process was patented by William Hoopes, a chemist of the Aluminum Company of America (ALCOA) in 1925.

Julia Brainerd Hall was the sister of American scientist Charles Martin Hall. She supported him in his discovery of the Hall process for extracting aluminium from its ore. She was also a still-life painter who exhibited at the Edgar Adams Gallery in Cleveland.

Howmet Aerospace Inc. is an American aerospace company based in Pittsburgh, Pennsylvania. The company manufactures components for jet engines, fasteners and titanium structures for aerospace applications, and forged aluminum wheels for heavy trucks.

Aluminium metal is very rare in native form, and the process to refine it from ores is complex, so for most of human history it was unknown. However, the compound alum has been known since the 5th century BCE and was used extensively by the ancients for dyeing. During the Middle Ages, its use for dyeing made it a commodity of international commerce. Renaissance scientists believed that alum was a salt of a new earth; during the Age of Enlightenment, it was established that this earth, alumina, was an oxide of a new metal. Discovery of this metal was announced in 1825 by Danish physicist Hans Christian Ørsted, whose work was extended by German chemist Friedrich Wöhler.