Related Research Articles

An electric motor is a machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. An electric generator is mechanically identical to an electric motor, but operates in reverse, converting mechanical energy into electrical energy.

Electrical wiring is an electrical installation of cabling and associated devices such as switches, distribution boards, sockets, and light fittings in a structure.

High voltage electricity refers to electrical potential large enough to cause injury or damage. In certain industries, high voltage refers to voltage above a certain threshold. Equipment and conductors that carry high voltage warrant special safety requirements and procedures.

The IP code or ingress protection code indicates how well a device is protected against water and dust. It is defined by the International Electrotechnical Commission (IEC) under the international standard IEC 60529 which classifies and provides a guideline to the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water. It is published in the European Union by the European Committee for Electrotechnical Standardization (CENELEC) as EN 60529.

In electrical engineering, a disconnector, disconnect switch or isolator switch is a type of switching device with visible contacts, used to ensure that an electrical circuit is completely de-energized for service or maintenance. They are often found in electrical distribution and industrial applications, where machinery must have its source of driving power removed for adjustment or repair. Disconnectors can be operated manually or by a motor, and may be paired with an earthing switch to ground the portion that has been isolated from the system for ensuring the safety of equipment and the personnel working on it.

In electrical and safety engineering, hazardous locations are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations can provide an ignition source, due to electrical arcing, or high temperatures. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations.

Lock out, tag out or lockout–tagout (LOTO) is a safety procedure used to ensure that dangerous equipment is properly shut off and not able to be started up again prior to the completion of maintenance or repair work. It requires that hazardous energy sources be "isolated and rendered inoperative" before work is started on the equipment in question. The isolated power sources are then locked and a tag is placed on the lock identifying the worker and reason the LOTO is placed on it. The worker then holds the key for the lock, ensuring that only they can remove the lock and start the equipment. This prevents accidental startup of equipment while it is in a hazardous state or while a worker is in direct contact with it.

The ATEX directives are two of the EU directives describing the minimum safety requirements for workplaces and equipment used in explosive atmospheres. The name is an initialization of the term ATmosphères EXplosibles.

IEC standard 61511 is a technical standard which sets out practices in the engineering of systems that ensure the safety of an industrial process through the use of instrumentation. Such systems are referred to as Safety Instrumented Systems. The title of the standard is "Functional safety - Safety instrumented systems for the process industry sector".

Intrinsic safety (IS) is a protection technique for safe operation of electrical equipment in hazardous areas by limiting the energy, electrical and thermal, available for ignition. In signal and control circuits that can operate with low currents and voltages, the intrinsic safety approach simplifies circuits and reduces installation cost over other protection methods. Areas with dangerous concentrations of flammable gases or dust are found in applications such as petrochemical refineries and mines. As a discipline, it is an application of inherent safety in instrumentation. High-power circuits such as electric motors or lighting cannot use intrinsic safety methods for protection.

Magnet wire or enameled wire is a copper or aluminium wire coated with a very thin layer of insulation. It is used in the construction of transformers, inductors, motors, generators, speakers, hard disk head actuators, electromagnets, electric guitar pickups, and other applications that require tight coils of insulated wire.

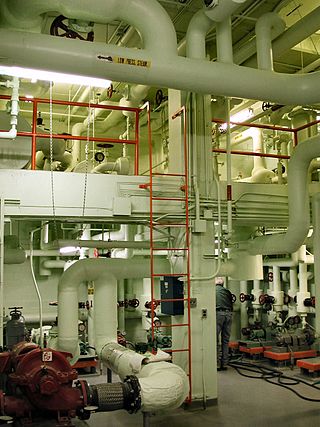

A pipefitter or steamfitter is a tradesman who installs, assembles, fabricates, maintains, and repairs mechanical piping systems. Pipefitters usually begin as helpers or apprentices. Journeyman pipefitters deal with industrial/commercial/marine piping and heating/cooling systems. Typical industrial process pipe is under high pressure, which requires metals such as carbon steel, stainless steel, and many different alloy metals fused together through precise cutting, threading, grooving, bending, and welding. A plumber concentrates on lower pressure piping systems for sewage and potable tap water in the industrial, commercial, institutional, or residential atmosphere. Utility piping typically consists of copper, PVC, CPVC, polyethylene, and galvanized pipe, which is typically glued, soldered, or threaded. Other types of piping systems include steam, ventilation, hydraulics, chemicals, fuel, and oil.

The Control of Substances Hazardous to Health Regulations 2002 is a United Kingdom Statutory Instrument which states general requirements imposed on employers to protect employees and other persons from the hazards of substances used at work by risk assessment, control of exposure, health surveillance and incident planning. There are also duties on employees to take care of their own exposure to hazardous substances and prohibitions on the import of certain substances into the European Economic Area. The regulations reenacted, with amendments, the Control of Substances Hazardous to Work Regulations 1999 and implement several European Union directives.

The Professional Electrical Apparatus Reconditioning League or PEARL is an international professional organization and standards group based in Denver, Colorado. PEARL is focused on developing ethical business practices and technical standards related to inspecting, testing, and reconditioning circuit breakers, transformer, motor controls, switchgear, disconnect switches, protective relays, bus duct, motor starters and other electrical equipment and apparatus used in the electrical distribution systems of commercial, industrial, and utility facilities.

Premium efficiency, when used in reference to specific types of Electric Motors, is a class of motor efficiency.

IEC 60204-1 / EN 60204 Safety of machinery – Electrical equipment of machines – Part 1: General requirements

An alternator is a type of electric generator used in modern automobiles to charge the battery and to power the electrical system when its engine is running.

CompEx is a global certification scheme for electrical and mechanical craftspersons and designers working in potentially explosive atmospheres. The scheme is operated by JTLimited, UK and is accredited by UKAS to ISO/IEC 17024.

Workplace safety standards are sets of standards developed with the goal of reducing risk from occupational hazards.

References

- ↑ Boxall, Peter (February 1994). "Trading Places". Business North: 65.[ permanent dead link ]

- ↑ Lawton, William (1946). The Burden Of Other Days. p. 3.[ permanent dead link ]

- 1 2 3 Joseph, Bob (June 1970). "On to the next quarter". Electrical Machinery. 79. 18: 11.[ permanent dead link ]

- ↑ "Maintenance for motors in hazardous area environments - to be presented at HazardEx 2012" . Retrieved 2018-11-13.

- ↑ "AEMT Code of Practice on Safety in Electrical Testing". AEMT. Archived from the original on 2014-09-06.

- ↑ "AC Three Phase Stator Winding Connections". AEMT. Archived from the original on 2014-09-06.

- ↑ "AEMT Code of Practice on Handling, Use and Storage of Hazardous Substances". AEMT.[ permanent dead link ]

- ↑ "IEC60079-19". IEC.

- ↑ "The Effect Of Repair/Rewinding On Motor Efficiency" (PDF). Electrical Apparatus Service Association. Archived from the original (PDF) on 21 December 2014. Retrieved 28 March 2014.

- ↑ "Explosive Atmospheres: Equipment Repair Overhaul and Reclamation". IEC Ex.

- ↑ "Ex Labels and Reference Data" (PDF). AEMT.

- ↑ "AEMT Journal". AEMT. Archived from the original on 2013-09-28. Retrieved 2014-03-31.

- ↑ "AEMT Yearbook". AEMT. Archived from the original on 2013-09-28. Retrieved 2014-03-31.