Hydropower, also known as water power, is the use of falling or fast-running water to produce electricity or to power machines. This is achieved by converting the gravitational potential or kinetic energy of a water source to produce power. Hydropower is a method of sustainable energy production. Hydropower is now used principally for hydroelectric power generation, and is also applied as one half of an energy storage system known as pumped-storage hydroelectricity. Hydropower is an attractive alternative to fossil fuels as it does not directly produce carbon dioxide or other atmospheric pollutants and it provides a relatively consistent source of power. Nonetheless, it has economic, sociological, and environmental downsides and requires a sufficiently energetic source of water, such as a river or elevated lake. International institutions such as the World Bank view hydropower as a low-carbon means for economic development.

A turbine is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical power when combined with a generator. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Early turbine examples are windmills and waterwheels.

A water turbine is a rotary machine that converts kinetic energy and potential energy of water into mechanical work.

École Centrale Paris was a French grande école in engineering and science. It was also known by its official name École Centrale des Arts et Manufactures. In 2015, École Centrale Paris merged with Supélec to form CentraleSupélec, a constituent college of the University of Paris-Saclay.

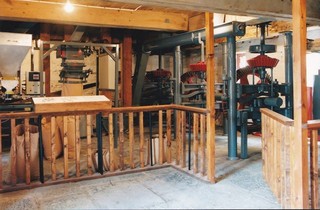

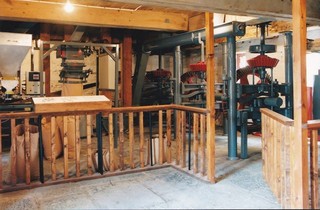

A watermill or water mill is a mill that uses hydropower. It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering. Such processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may comprise gristmills, sawmills, paper mills, textile mills, hammermills, trip hammering mills, rolling mills, wire drawing mills.

A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a wheel, with a number of blades or buckets arranged on the outside rim forming the driving car. Water wheels were still in commercial use well into the 20th century but they are no longer in common use. Uses included milling flour in gristmills, grinding wood into pulp for papermaking, hammering wrought iron, machining, ore crushing and pounding fibre for use in the manufacture of cloth.

A millwright is a craftsperson or skilled tradesperson who installs, dismantles, maintains, repairs, reassembles, and moves machinery in factories, power plants, and construction sites.

The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.

Lester Allan Pelton was an American inventor who contributed significantly to the development of hydroelectricity and hydropower in the American Old West as well as world-wide. In the late 1870s, he invented the Pelton water wheel, at that time the most efficient design of the impulse water turbine. Recognized as one of the fathers of hydroelectric power, he was awarded the Elliott Cresson Medal during his lifetime and is an inductee of the National Inventors Hall of Fame.

Improvements to the steam engine were some of the most important technologies of the Industrial Revolution, although steam did not replace water power in importance in Britain until after the Industrial Revolution. From Englishman Thomas Newcomen's atmospheric engine, of 1712, through major developments by Scottish inventor and mechanical engineer James Watt, the steam engine began to be used in many industrial settings, not just in mining, where the first engines had been used to pump water from deep workings. Early mills had run successfully with water power, but by using a steam engine a factory could be located anywhere, not just close to a water source. Water power varied with the seasons and was not always available.

École nationale supérieure des mines de Saint-Étienne, also called École des Mines de Saint-Étienne or simply Mines Saint-Étienne and commonly abbreviated EMSE is a prestigious French graduate engineering school training engineers and carrying out industry-oriented research. Its function is to support the development of its students and of companies through a range of courses and fields of research, from the initial training of generalist engineers ingénieurs civils des mines, to PhD teaching; from material sciences to micro-electronics via process engineering, mechanics, the environment, civil engineering, finance, computer science and health engineering.

The concept of engineering has existed since ancient times as humans devised fundamental inventions such as the pulley, lever, and wheel. Each of these inventions is consistent with the modern definition of engineering, exploiting basic mechanical principles to develop useful tools and objects.

The Jonval turbine is a water turbine design invented in France in 1837 and introduced to the United States around 1850 and were widely used. The Jonval turbine is a "mixed-flow" turbine design. Mixed-flow designs were well suited for the low-head applications common in the eastern United States. The smaller size, higher speed, higher power, lower cost, and ability to operate efficiently with variable water levels caused these and other types of hydraulic turbines to replace the vertical waterwheel as the primary source of power in American industries.

Claude Burdin was a French engineer. Born in Lépin-le-Lac, Savoie, when it was known as the Duchy of Savoy, he was professor at the school of mines, École nationale supérieure des mines de Saint-Étienne, in Saint-Étienne. He became a French citizen on 4 June 1817. He proposed the concept and developed the term turbine from the Greek word τύρβη, meaning "whirling" or a "vortex".

The Sagebien wheel is a type of water wheel invented by Alphonse Sagebien of France, a hydrological engineer and a graduate of the École Centrale des Arts et Manufactures. It was one of the most efficient breastshot water wheel designs of its era; when working on a low head of water, the Sagebien wheel could reach efficiencies of up to 90% in real-world examples.

A water-returning engine was an early form of stationary steam engine, developed at the start of the Industrial Revolution in the middle of the 18th century. The first beam engines did not generate power by rotating a shaft but were developed as water pumps, mostly for draining mines. By coupling this pump with a water wheel, they could be used to drive machinery.

Cavan Water Mill, formerly Lifeforce Mill, is a 19th-century mill located in Cavan. The current building dates from 1846 and contains a notable MacAdam water turbine. Having been abandoned in the 1960s, it was restored as a museum and visitor attraction in the 1990s.

Robert Barker was a British physician and inventor. He was a Fellow of the Royal Society from 1732.

Auguste Rateau was an engineer and industrialist born in Royan, France, specializing in turbines.

The Holyoke Testing Flume was a hydraulic testing laboratory and apparatus in Holyoke, Massachusetts, operated by the Holyoke Water Power Company from 1870 to 1932, and used to test the performance of water turbine designs, completing 3,176 tests of efficiency in that time. It was described by Robert E. Horton in court testimony as the only facility of its kind in the 19th and early 20th century, which made possible the standardization of American water turbines. Indeed Clemens Herschel, who managed and redesigned the facility in the 1880s, later described it in Congressional testimony as the "first modern hydraulic laboratory" in the United States and the world. It was through Herschel's need to determine the water power consumption of different mills, and in this testing system that he would invent the Venturi meter, the first accurate means of measuring large-scale flows, which still retains widespread use in modern technology today.