The Chalcolithic was an archaeological period characterized by the increasing use of smelted copper. It followed the Neolithic and preceded the Bronze Age. It occurred at different periods in different areas, but was absent in some parts of the world, such as Russia, where there was no well-defined Copper Age between the Stone and Bronze ages. Stone tools were still predominantly used during this period.

Dar es Salaam is the largest city and financial hub of Tanzania. It is also the capital of the Dar es Salaam Region. With a population of over five million people, Dar es Salaam is the largest city in East Africa and the sixth-largest in Africa. Located on the Swahili coast, Dar es Salaam is an important economic center and one of the fastest-growing cities in the world.

The Iron Age is the final epoch of the three historical Metal Ages, after the Chalcolithic and Bronze Age. It has also been considered as the final Age of the three-age division starting with prehistory and progressing to protohistory. In this usage, it is preceded by the Stone Age and Bronze Age. These concepts originated for describing Iron Age Europe and the Ancient Near East. Still, they now include other parts of the Old World.

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron, copper, silver, tin, lead and zinc. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal behind. The reducing agent is commonly a fossil fuel source of carbon, such as carbon monoxide from incomplete combustion of coke—or, in earlier times, of charcoal. The oxygen in the ore binds to carbon at high temperatures as the chemical potential energy of the bonds in carbon dioxide is lower than that of the bonds in the ore.

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being supplied above atmospheric pressure.

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper ores consists of a series of physical, chemical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

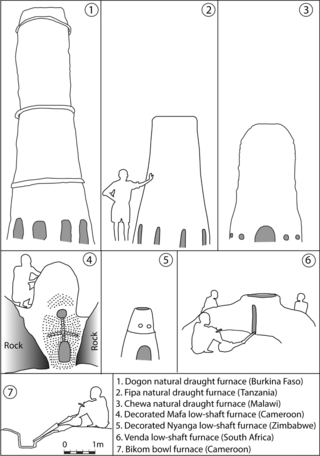

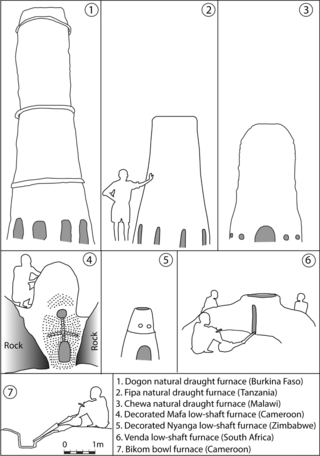

A bloomery is a type of metallurgical furnace once used widely for smelting iron from its oxides. The bloomery was the earliest form of smelter capable of smelting iron. Bloomeries produce a porous mass of iron and slag called a bloom. The mix of slag and iron in the bloom, termed sponge iron, is usually consolidated and further forged into wrought iron. Blast furnaces, which produce pig iron, have largely superseded bloomeries.

Following Tanganyika's independence (1961) and unification with Zanzibar (1964), leading to the formation of the state of Tanzania, President Julius Nyerere emphasised a need to construct a national identity for the citizens of the new country. To achieve this, Nyerere provided what has been regarded by some commentators as one of the most successful cases of ethnic repression and identity transformation in Africa.

The Pare people are members of an ethnic group indigenous to the Pare Mountains of northern Tanzania, part of the Kilimanjaro Region. Historically, Pareland was also known as Vuasu and Vughonu to its inhabitants. The location lies on one of the northern routes of the historic East-African long-distance trade, connecting the hinterland with the coast of the Indian Ocean.

The Haya are a Bantu ethnic group based in Kagera Region, northwestern Tanzania, on the western side of Lake Victoria. With over one million people, it is estimated the Haya make up approximately 4% of the population of Tanzania. Historically, the Haya have had a complex kingship-based political system. Agriculture, particularly banana farming, is central to Haya economic life. They are credited with the independent development of carbon steel dating to 2000 years ago using pre-heating techniques.

Ferrous metallurgy is the metallurgy of iron and its alloys. The earliest surviving prehistoric iron artifacts, from the 4th millennium BC in Egypt, were made from meteoritic iron-nickel. It is not known when or where the smelting of iron from ores began, but by the end of the 2nd millennium BC iron was being produced from iron ores in the region from Greece to India, The use of wrought iron was known by the 1st millennium BC, and its spread defined the Iron Age. During the medieval period, smiths in Europe found a way of producing wrought iron from cast iron, in this context known as pig iron, using finery forges. All these processes required charcoal as fuel.

Iron metallurgy in Africa developed within Africa; though initially assumed to be of external origin, this assumption has been rendered untenable; archaeological evidence has increasingly supported an indigenous origin. Some recent studies date the inception of iron metallurgy in Africa between 3000 BCE and 2500 BCE. Archaeometallurgical scientific knowledge and technological development originated in numerous centers of Africa; the centers of origin were located in West Africa, Central Africa, and East Africa; consequently, as these origin centers are located within inner Africa, these archaeometallurgical developments are thus native African technologies.

Felix A. Chami is an archaeologist from Tanzania. He is a professor at the University of Dar es Salaam, focusing on East African coastal archaeology. Dr. Chami discovered, on the island of Mafia and Juani, artifacts that revealed East Africa as being integral to the Indian Ocean trade. Chami earned a first degree in sociology from the University of Dar es Salaam in 1986, a master's degree in anthropology from Brown University in 1988 and a Ph.D. in archaeology from Uppsala University in 1994.

Archaeometallurgical slag is slag discovered and studied in the context of archaeology. Slag, the byproduct of iron-working processes such as smelting or smithing, is left at the iron-working site rather than being moved away with the product. As it weathers well, it is readily available for study. The size, shape, chemical composition and microstructure of slag are determined by features of the iron-working processes used at the time of its formation.

Copper metallurgy in Africa encompasses the study of copper production across the continent and an understanding of how it influenced aspects of African archaeology.

Non-ferrous extractive metallurgy is one of the two branches of extractive metallurgy which pertains to the processes of reducing valuable, non-iron metals from ores or raw material. Metals like zinc, copper, lead, aluminium as well as rare and noble metals are of particular interest in this field, while the more common metal, iron, is considered a major impurity. Like ferrous extraction, non-ferrous extraction primarily focuses on the economic optimization of extraction processes in separating qualitatively and quantitatively marketable metals from its impurities (gangue).

Kemondo Iron Age Sites or KM2 and KM3 are Early Iron Age complex industrial archaeological sites in Kemondo ward, Bukoba Rural District, Kagera Region, Tanzania, excavated by a team led by archaeologist Peter Schmid in the late 1970s and 1980s. The excavations aimed at better understanding the iron smelting process and its ritual aspects in East Africa. At the KM2 and KM3 sites, Schmidt tested the hypothesis that the high combustion temperature of furnaces, discovered to be between 1,350–1,400 °C (2,460–2,550 °F), was caused by the preheating of air blasts. Preheating has been suggested to be a distinct feature of African Early Iron Age smelting techniques by ethnographic observations of the Haya people of northwestern Tanzania.

Adria Jean LaViolette is an American archaeologist at the University of Virginia. She is a specialist in Swahili archaeology and is the joint editor of The Swahili World.

Amini Aza Mturi was a Tanzanian archaeologist and director of the Tanzanian Division of Antiquities between 1968 and 1981. He has been described as "one of the founding fathers of archaeology in Tanzania".

Kwale Island also known as Kuvala Island is a historic island located inside the Mafia Channel, in Kisiju ward of Mkuranga District in southern Pwani Region of Tanzania. 7.1 square kilometres is the size of Kwale Island.