Masonry is the craft of building a structure with brick, stone, or similar material, including mortar plastering which are often laid in, bound, and pasted together by mortar. The term masonry can also refer to the building units themselves.

Timber framing and "post-and-beam" construction are traditional methods of building with heavy timbers, creating structures using squared-off and carefully fitted and joined timbers with joints secured by large wooden pegs. If the structural frame of load-bearing timber is left exposed on the exterior of the building it may be referred to as half-timbered, and in many cases the infill between timbers will be used for decorative effect. The country most known for this kind of architecture is Germany, where timber-framed houses are spread all over the country.

Tilt-up,tilt-slab or tilt-wall is a type of building and a construction technique using concrete. Though it is a cost-effective technique with a shorter completion time, poor performance in earthquakes has mandated significant seismic retrofit requirements in older buildings.

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with recent experiences with large earthquakes near urban centers, the need of seismic retrofitting is well acknowledged. Prior to the introduction of modern seismic codes in the late 1960s for developed countries and late 1970s for many other parts of the world, many structures were designed without adequate detailing and reinforcement for seismic protection. In view of the imminent problem, various research work has been carried out. State-of-the-art technical guidelines for seismic assessment, retrofit and rehabilitation have been published around the world – such as the ASCE-SEI 41 and the New Zealand Society for Earthquake Engineering (NZSEE)'s guidelines. These codes must be regularly updated; the 1994 Northridge earthquake brought to light the brittleness of welded steel frames, for example.

A concrete block, also known as a cinder block in North American English, breeze block in British English, concrete masonry unit (CMU), or by various other terms, is a standard-size rectangular block used in building construction. The use of blockwork allows structures to be built in the traditional masonry style with layers of staggered blocks.

Insulating concrete form or insulated concrete form (ICF) is a system of formwork for reinforced concrete usually made with a rigid thermal insulation that stays in place as a permanent interior and exterior substrate for walls, floors, and roofs. The forms are interlocking modular units that are dry-stacked and filled with concrete. The units lock together somewhat like Lego bricks and create a form for the structural walls or floors of a building. ICF construction has become commonplace for both low rise commercial and high performance residential construction as more stringent energy efficiency and natural disaster resistant building codes are adopted.

A cruck or crook frame is a curved timber, one of a pair, which support the roof of a building, historically used in England and Wales. This type of timber framing consists of long, generally naturally curved, timber members that lean inwards and form the ridge of the roof. These posts are then generally secured by a horizontal beam which then forms an "A" shape. Several of these "crooks" are constructed on the ground and then lifted into position. They are then joined together by either solid walls or cross beams which aid in preventing 'racking'.

Framing, in construction, is the fitting together of pieces to give a structure, particularly a building, support and shape. Framing materials are usually wood, engineered wood, or structural steel. The alternative to framed construction is generally called mass wall construction, where horizontal layers of stacked materials such as log building, masonry, rammed earth, adobe, etc. are used without framing.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible. Steel frame has displaced its predecessor, the iron frame, in the early 20th century.

Fireproofing is rendering something resistant to fire, or incombustible; or material for use in making anything fire-proof. It is a passive fire protection measure. "Fireproof" or "fireproofing" can be used as a noun, verb or adjective; it may be hyphenated ("fire-proof").

Portal frame is a construction technique where vertical supports are connected to horizontal beams or trusses via fixed joints with designed-in moment-resisting capacity. The result is wide spans and open floors.

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and maneuvered into place; examples include precast beams, and wall panels, floors, roofs, and piles. In contrast, cast-in-place concrete is poured into site-specific forms and cured on site.

Gedung Kuning is a Malay historical residence in Singapore. Located at 73 Sultan Gate, Gedung Kuning stands just outside the Malay Heritage Centre, near Masjid Sultan in the historic district of Kampong Glam in Singapore. However, from 1919 to 1925, the Gedung Kuning's address was 33 Sultan Gate. Once forming an annexe to the adjacent palace of Singapore's Malay rulers, Istana Kampong Glam, it became the private residence of Haji Yusoff, a prominent Malayo-Javanese merchant and four generations of his family. Together with the Istana, the compound was refurbished as part of the development of the Malay Heritage Centre in 2004.

Masonry veneer walls consist of a single non-structural external layer of masonry, typically made of brick, stone or manufactured stone. Masonry veneer can have an air space behind it and is technically called "anchored veneer". A masonry veneer attached directly to the backing is called "adhered veneer". The innermost element is structural, and may consist of masonry, concrete, timber or metal frame.

The construction of State Farm Center, originally known as the Assembly Hall, at the University of Illinois at Urbana–Champaign consisted of building a huge indoor arena with a 400-foot-diameter (120 m) concrete dome whose center height is 125 feet (38 m) above the center floor, and which weighs 10 million pounds. The building is considered an engineering marvel because of the unique method used to build the concrete roof. State Farm Center, the first-ever concrete dome arena, hosts the campus's teams in men's and women's basketball, numerous concerts and other events. It holds sentimental value for numerous alumni and fans alike and attracts attention for its design and construction. The construction of the Assembly Hall was conceived to provide UIUC with needed space for ceremonies and athletic events. The university’s population had outgrown the largest building on campus at that time, the Auditorium, and desired one building that could hold the entire university class. The design of the new building, by Max Abramovitz, called for the construction of one of the world’s largest edge-supported structure. The assembly hall was completed in 1963, and was dedicated on Honors Day, Friday May 3.

Rural Khmer houses are a traditional house type of the Khmer people.

The Tribune Review Publishing Company Building was designed by architect Louis Kahn as the office and printing plant for the Tribune-Review newspaper in Greensburg, Pennsylvania, about 35 miles southeast of Pittsburgh. Although not in his usual line of work, Kahn accepted the commission at the request of William Huff, an architect on his staff who was related to the newspaper's owner. The building is considered to be one of Kahn's relatively minor works, but it has some interesting features nonetheless. Kahn began work on the design in 1958 and the building was completed in 1962.

A windpost is a structural item used in the design and construction of masonry walls to increase lateral wall stability and protect them against damage from horizontal forces imposed by wind pressure, crowd or handrail loads. They are normally constructed from mild steel channel sections, supported at the head and the foot between floor slab levels and/or the principal steelwork sections forming the structural frame of the building. In cavity walls, the windpost will typically be fixed into the inner and outer leafs of the wall by specialist fixings and fastenings at regular intervals along its length. The windposts will be spaced along the walls of the building at regular intervals as calculated by the engineer to suit the required loadings.

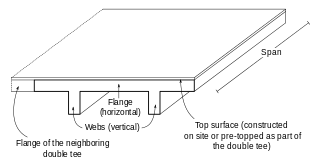

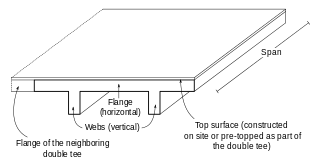

A double tee or double-T beam is a load-bearing structure that resembles two T-beams connected to each other side by side. The strong bond of the flange and the two webs creates a structure that is capable of withstanding high loads while having a long span. The typical sizes of double tees are up to 15 feet (4.6 m) for flange width, up to 5 feet (1.5 m) for web depth, and up to 80 feet (24 m) or more for span length. Double tees are pre-manufactured from prestressed concrete which allows construction time to be shortened.