A brick is a type of construction material used to build walls, pavements and other elements in masonry construction. Properly, the term brick denotes a unit primarily composed of clay, but is now also used informally to denote units made of other materials or other chemically cured construction blocks. Bricks can be joined using mortar, adhesives or by interlocking. Bricks are usually produced at brickworks in numerous classes, types, materials, and sizes which vary with region, and are produced in bulk quantities.

A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing and to transform many other materials.

Coke is a grey, hard, and porous coal-based fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern.

A briquette is a compressed block of coal dust or other combustible biomass material used for fuel and kindling to start a fire. The term derives from the French word brique, meaning brick.

A clamp is a compact heap, mound or pile of materials. A storage clamp is used in the agricultural industry for temporary storage of root crops such as potato, turnip, rutabaga, mangelwurzel, and sugar beet.

A brickworks, also known as a brick factory, is a factory for the manufacturing of bricks, from clay or shale. Usually a brickworks is located on a clay bedrock, often with a quarry for clay on site. In earlier times bricks were made at brickfields, which would be returned to agricultural use after the clay layer was exhausted.

Bizen ware is a type of Japanese pottery traditionally from Bizen province, presently a part of Okayama prefecture.

Devil's Backbone State Forest is a 705.5-acre (285.5 ha) state forest in Shenandoah County, Virginia. It lies on the slope of North Mountain in the drainage area of Cedar Creek near Star Tannery west of Strasburg. The forest was established by a grant by John and Bernice Hoffman, who owned the land since 1950.

A brickyard or brickfield is a place or yard where bricks are made, fired, and stored, or sometimes sold or otherwise distributed from. Brick makers work in a brick yard. A brick yard may be constructed near natural sources of clay or on or near a construction site if necessity or design requires the bricks to be made locally.

Charcoal is a lightweight black carbon residue produced by strongly heating wood in minimal oxygen to remove all water and volatile constituents. In the traditional version of this pyrolysis process, called charcoal burning, often by forming a charcoal kiln, the heat is supplied by burning part of the starting material itself, with a limited supply of oxygen. The material can also be heated in a closed retort. Modern "charcoal" briquettes used for outdoor cooking may contain many other additives, e.g. coal.

A bottle oven or bottle kiln is a type of kiln. The word 'bottle' refers to the shape of the structure and not to the kiln's products, which are usually pottery, not glass.

A brickfield is a field or other open site where bricks are made. Land may be leased by an owner to a brickmaster, by whom the manufacture of bricks may be conducted. Historically, the topsoil was typically removed and the clay beneath was stripped and mixed with chalk and ash to make bricks. In pre-19th-century England,

[i]n most areas the brickfield owner hired a brickmaster at a price per thousand bricks to superintend the site and take full responsibility for the output of the operations. He in turn contracted with moulders to temper, mould and hack the bricks. Each moulder then hired his own 'gang' of subsidiary labourers and acted as their employer.

The Birch Creek Charcoal Kilns are a group of beehive-shaped clay charcoal kilns near Leadore, Idaho, built in 1886. They were listed on the National Register of Historic Places in 1972.

The Tybo Charcoal Kilns are a pair of charcoal kilns located 4 miles (6.4 km) north of Tybo, Nevada. Both kilns are 30 feet (9.1 m) tall and 25 feet (7.6 m) in diameter and were built from rocks and mud. The kilns each have three openings: a top opening, a door at ground level, and a rear window with a ramp for wood wagons. The kilns were among 15 built in 1874 for the Tybo Consolidated Company. The company, which mined the region's silver, used charcoal to fuel its smelting furnace. To acquire its fuel, it imported wood from nearby hills, which it then converted to charcoal in the kilns.

Artists' charcoal is charcoal used as a dry art medium. Both compressed charcoal and charcoal sticks are used. The marks it leaves behind on paper are much less permanent that with other media such as graphite, and so lines can easily be erased and blended. Charcoal can produce lines that are very light or intensely black. The dry medium can be applied to almost any surface from smooth to very coarse. Fixatives are used with charcoal drawings to solidify the position to prevent erasing or rubbing off of charcoal dusts.

A charcoal pile or charcoal clamp is a carefully arranged pile of wood, covered by turf or other layer, inside which a fire is lit in order to produce charcoal. The pile is tended by a charcoal burner. It is similar to a charcoal kiln, but the latter is usually a permanent structure made of materials such as stone.

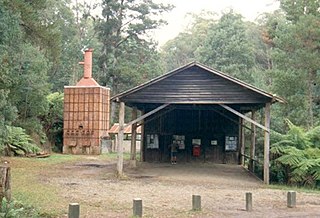

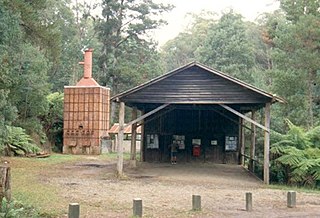

Kurth Kiln was established by the Forests Commission Victoria in 1941 on a site about 7 km north of Gembrook on the Tomahawk Creek.