Bristol blue glass has been made in Bristol, England, since the 18th century, with a break between the 1920s and 1980s.

Bristol blue glass has been made in Bristol, England, since the 18th century, with a break between the 1920s and 1980s.

During the late 18th century Richard Champion, a Bristol merchant and potter, making Bristol porcelain, was working with a chemist, William Cookworthy. [1] Cookworthy began a search for good quality cobalt oxide to give the blue glaze decoration on the white porcelain and obtained exclusive import rights to all the cobalt oxide from the Royal Saxon Cobalt Works in Saxony. [2] It is uncertain when Bristol blue glass was first made but the quality and beauty of the glass swiftly gained popularity, with seventeen glass houses being set up in the city. [3]

Lazarus and Isaac Jacobs were the most famous makers of Bristol blue glass in the 1780s. Lazarus Jacobs was a Jewish immigrant to Bristol from Frankfurt am Main, Germany. In 1774, at the age of seventeen, Isaac joined his father's glass cutting firm at 108 Temple Street, Bristol, and launched Bristol Blue glass as a national brand, using the cobalt oxide Cookworthy imported. Isaac was responsible for the great growth of the company, and the expansion of its goods. [4] Their company held a royal warrant and made glass for the aristocrats of Europe. [5] Bristol’s glass makers were invited to demonstrate their skills at the Great Exhibition of 1851, opened by Queen Victoria and Prince Albert. At this period cranberry glass was made for the first time by adding 24 carat gold to lead crystal, giving the glass its ruby red tones.

Production ceased in about 1923. [6]

Around 1970 Thomas Webb & Sons of Stourbridge made a range of about ten Bristol blue glass shapes, but had to stop as they found cobalt dust was contaminating their lead crystal. At the request of John Stott, the managing director of Thomas Webb (who closed down in 1990), Nazeing Glass of Broxbourne, Herts, supplied the Bristol Museum and Art Gallery Shop with a range of some twenty glass shapes, all based on 18th century inspired designs, from 1975 until 1990. Bristol-based glass makers James Adlington and Peter Sinclair held their Hot Glass exhibition in 1988 at Hand Made Glass, Bristol, which led to a revival of Bristol's hand blown glass industry, and to the creation of a company that has spawned the careers of many other studio glassmakers in the southwest of England. [7] Today, Bristol Blue Glass is produced by The Original Bristol Blue Glass Ltd in Brislington, established in 1988.

In the 1990s, John Harvey & Sons of Bristol began to sell Bristol Cream sherry in bottles made from Bristol blue, after a period of over 100 years during which blue bottles had been associated with the sale of dangerous or poisonous liquids.

The glass contains cobalt oxide, which creates a deep yet bright blue, and 24% lead oxide (PbO). [8]

Delftware or Delft pottery, also known as Delft Blue or as delf, is a general term now used for Dutch tin-glazed earthenware, a form of faience. Most of it is blue and white pottery, and the city of Delft in the Netherlands was the major centre of production, but the term covers wares with other colours, and made elsewhere. It is also used for similar pottery, English delftware.

A bottle is a narrow-necked container made of an impermeable material in various shapes and sizes that stores and transports liquids. Its mouth, at the bottling line, can be sealed with an internal stopper, an external bottle cap, a closure, or induction sealing.

Cobalt blue is a blue pigment made by sintering cobalt(II) oxide with aluminum(III) oxide (alumina) at 1200 °C. Chemically, cobalt blue pigment is cobalt(II) oxide-aluminium oxide, or cobalt(II) aluminate, CoAl2O4. Cobalt blue is lighter and less intense than the (iron-cyanide based) pigment Prussian blue. It is extremely stable and historically has been used as a coloring agent in ceramics (especially Chinese porcelain), jewelry, and paint. Transparent glasses are tinted with the silica-based cobalt pigment "smalt".

William Cookworthy was an English Quaker minister, a successful pharmacist and an innovator in several fields of technology. He was the first person in Britain to discover how to make hard-paste porcelain, like that imported from China. He subsequently discovered china clay in Cornwall. In 1768 he founded a works at Plymouth for the production of Plymouth porcelain; in 1770 he moved the factory to Bristol, to become Bristol porcelain, before selling it to a partner in 1773.

"Blue and white pottery" covers a wide range of white pottery and porcelain decorated under the glaze with a blue pigment, generally cobalt oxide. The decoration is commonly applied by hand, originally by brush painting, but nowadays by stencilling or by transfer-printing, though other methods of application have also been used. The cobalt pigment is one of the very few that can withstand the highest firing temperatures that are required, in particular for porcelain, which partly accounts for its long-lasting popularity. Historically, many other colours required overglaze decoration and then a second firing at a lower temperature to fix that.

Islamic pottery occupied a geographical position between Chinese ceramics, and the pottery of the Byzantine Empire and Europe. For most of the period, it made great aesthetic achievements and influence as well, influencing Byzantium and Europe. The use of drinking and eating vessels in gold and silver, the ideal in ancient Rome and Persia as well as medieval Christian societies, is prohibited by the Hadiths, with the result that pottery and glass were used for tableware by Muslim elites, as pottery also was in China but was much rarer in Europe and Byzantium. In the same way, Islamic restrictions greatly discouraged figurative wall painting, encouraging the architectural use of schemes of decorative and often geometrically patterned titles, which are the most distinctive and original specialty of Islamic ceramics.

Cobalt glass—known as "smalt" when ground as a pigment—is a deep blue coloured glass prepared by including a cobalt compound, typically cobalt oxide or cobalt carbonate, in a glass melt. Cobalt is a very intense colouring agent and very little is required to show a noticeable amount of colour.

Jasperware, or jasper ware, is a type of pottery first developed by Josiah Wedgwood in the 1770s. Usually described as stoneware, it has an unglazed matte "biscuit" finish and is produced in a number of different colours, of which the most common and best known is a pale blue that has become known as "Wedgwood blue". Relief decorations in contrasting colours are characteristic of jasperware, giving a cameo effect. The reliefs are produced in moulds and applied to the ware as sprigs.

Underglaze is a method of decorating pottery in which painted decoration is applied to the surface before it is covered with a transparent ceramic glaze and fired in a kiln. Because the glaze subsequently covers it, such decoration is completely durable, and it also allows the production of pottery with a surface that has a uniform sheen. Underglaze decoration uses pigments derived from oxides which fuse with the glaze when the piece is fired in a kiln. It is also a cheaper method, as only a single firing is needed, whereas overglaze decoration requires a second firing at a lower temperature.

Plymouth porcelain was the first English hard paste porcelain, made in the county of Devon from 1768 to 1770. After two years in Plymouth the factory moved to Bristol in 1770, where it operated until 1781, when it was sold and moved to Staffordshire as the nucleus of New Hall porcelain, which operated until 1835. The Plymouth factory was founded by William Cookworthy. The porcelain factories at Plymouth and Bristol were among the earliest English manufacturers of porcelain, and the first to produce the hard-paste porcelain produced in China and the German factories led by Meissen porcelain.

Ceramic glaze, or simply glaze, is a glassy coating on ceramics. It is used for decoration, to ensure the item is impermeable to liquids and to minimise the adherence of pollutants.

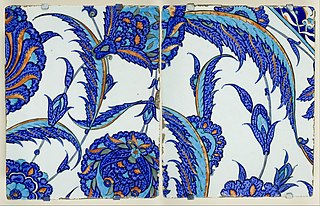

Iznik pottery, or Iznik ware, named after the town of İznik in Anatolia where it was made, is a decorated ceramic that was produced from the last quarter of the 15th century until the end of the 17th century. Turkish stylization is a reflection of Chinese Porcelain.

A frit is a ceramic composition that has been fused, quenched, and granulated. Frits form an important part of the batches used in compounding enamels and ceramic glazes; the purpose of this pre-fusion is to render any soluble and/or toxic components insoluble by causing them to combine with silica and other added oxides. However, not all glass that is fused and quenched in water is frit, as this method of cooling down very hot glass is also widely used in glass manufacture.

Bristol porcelain covers porcelain made in Bristol, England by several companies in the 18th and 19th centuries. The plain term "Bristol porcelain" is most likely to refer to the factory moved from Plymouth in 1770, the second Bristol factory. The product of the earliest factory is usually called Lund's Bristol ware and was made from about 1750 until 1752, when the operation was merged with Worcester porcelain; this was soft-paste porcelain.

Fritware, also known as stone-paste, is a type of pottery in which frit is added to clay to reduce its fusion temperature. The mixture may include quartz or other siliceous material. An organic compound such as gum or glue may be added for binding. The resulting mixture can be fired at a lower temperature than clay alone. A glaze is then applied on the surface.

Tin-glazed pottery is earthenware covered in lead glaze with added tin oxide which is white, shiny and opaque ; usually this provides a background for brightly painted decoration. It has been important in Islamic and European pottery, but very little used in East Asia. The pottery body is usually made of red or buff-colored earthenware and the white glaze imitated Chinese porcelain. The decoration on tin-glazed pottery is usually applied to the unfired glaze surface by brush with metallic oxides, commonly cobalt oxide, copper oxide, iron oxide, manganese dioxide and antimony oxide. The makers of Italian tin-glazed pottery from the late Renaissance blended oxides to produce detailed and realistic polychrome paintings.

Glass coloring and color marking may be obtained in several ways.

Tregonning Hill is the westerly of two granite hills overlooking Mount's Bay in west Cornwall, England, United Kingdom, the other being Godolphin Hill. They are approximately 6 kilometres (3.7 mi) west of the town of Helston. The Plymouth chemist William Cookworthy mixed china stone with kaolin, mined from the hill to make Plymouth porcelain in 1768; which was the first time hard-paste porcelain was made in Britain. Part of the hill is designated as a Site of Special Scientific Interest (SSSI) and at the date of notification (1994) was the only known site of western rustwort in Great Britain.

Lead-glazed earthenware is one of the traditional types of earthenware with a ceramic glaze, which coats the ceramic bisque body and renders it impervious to liquids, as terracotta itself is not. Plain lead glaze is shiny and transparent after firing. Coloured lead glazes are shiny and either translucent or opaque after firing. Three other traditional techniques are tin-glazed, which coats the ware with an opaque white glaze suited for overglaze brush-painted colored enamel designs; salt glaze pottery, also often stoneware; and the feldspathic glazes of Asian porcelain. Modern materials technology has invented new glazes that do not fall into these traditional categories.

Isaac Jacobs was a designer and manufacturer of Bristol blue glass, and is believed to be its inventor.