In telecommunications, RS-232 or Recommended Standard 232 is a standard originally introduced in 1960 for serial communication transmission of data. It formally defines signals connecting between a DTE such as a computer terminal or PC, and a DCE, such as a modem. The standard defines the electrical characteristics and timing of signals, the meaning of signals, and the physical size and pinout of connectors. The current version of the standard is TIA-232-F Interface Between Data Terminal Equipment and Data Circuit-Terminating Equipment Employing Serial Binary Data Interchange, issued in 1997. The RS-232 standard had been commonly used in computer serial ports and is still widely used in industrial communication devices.

Components of an electrical circuit are electrically connected if an electric current can run between them through an electrical conductor. An electrical connector is an electromechanical device used to create an electrical connection between parts of an electrical circuit, or between different electrical circuits, thereby joining them into a larger circuit.

A ferrule is any of a number of types of objects, generally used for fastening, joining, sealing, or reinforcement. They are often narrow circular rings made from metal, or less commonly, plastic. Ferrules are also often referred to as eyelets or grommets within the manufacturing industry.

IEC 60320 Appliance couplers for household and similar general purposes is a set of standards from the International Electrotechnical Commission (IEC) specifying non-locking connectors for connecting power supply cords to electrical appliances of voltage not exceeding 250 V (a.c.) and rated current not exceeding 16 A. Different types of connector are specified for different combinations of current, temperature and earthing requirements. Unlike IEC 60309 connectors, they are not coded for voltage; users must ensure that the voltage rating of the equipment is compatible with the mains supply. The standard uses the term coupler to encompass connectors on power cords and power inlets and outlets built into appliances.

A grommet is a ring or edge strip inserted into a hole through thin material, typically a sheet of textile fabric, sheet metal or composite of carbon fiber, wood or honeycomb. Grommets are generally flared or collared on each side to keep them in place, and are often made of metal, plastic, or rubber. They may be used to prevent tearing or abrasion of the pierced material or protection from abrasion of the insulation on the wire, cable, line being routed through the penetration, and to cover sharp edges of the piercing, or all of the above.

IEC 60309 is a series of international standards from the International Electrotechnical Commission (IEC) for "plugs, socket-outlets and couplers for industrial purposes". They are also referred to as "pin & sleeve" connectors in North America or as "CeeForm" connectors in the entertainment industry. The maximum voltage allowed by the standard is 1000 V DC or AC; the maximum current, 800 A; and the maximum frequency, 500 Hz. The ambient temperature range is −25 °C to 40 °C.

Electrical wiring is an electrical installation of cabling and associated devices such as switches, distribution boards, sockets, and light fittings in a structure.

Electrical wiring in the United Kingdom is commonly understood to be an electrical installation for operation by end users within domestic, commercial, industrial, and other buildings, and also in special installations and locations, such as marinas or caravan parks. It does not normally cover the transmission or distribution of electricity to them.

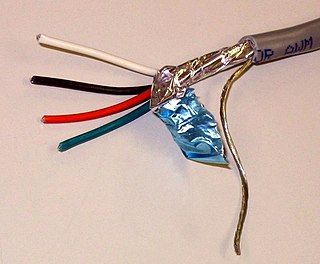

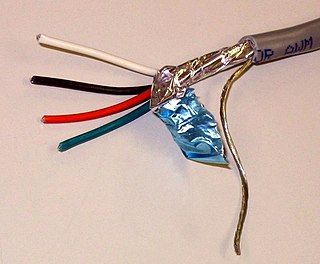

A shielded cable or screened cable is an electrical cable that has a common conductive layer around its conductors for electromagnetic shielding. This shield is usually covered by an outermost layer of the cable. Common types of cable shielding can most broadly be categorized as foil type, contraspiralling wire strands or both. A longitudinal wire may be necessary with dielectric spiral foils to short out each turn.

The IP code or ingress protection code indicates how well a device is protected against water and dust. It is defined by the International Electrotechnical Commission (IEC) under the international standard IEC 60529 which classifies and provides a guideline to the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water. It is published in the European Union by the European Committee for Electrotechnical Standardization (CENELEC) as EN 60529.

A stuffing box or gland package is an assembly which is used to house a gland seal. It is used to prevent leakage of fluid, such as water or steam, between sliding or turning parts of machine elements.

An electrical enclosure is a cabinet for electrical or electronic equipment to mount switches, knobs and displays and to prevent electrical shock to equipment users and protect the contents from the environment. The enclosure is the only part of the equipment which is seen by users. It may be designed not only for its utilitarian requirements, but also to be pleasing to the eye. Regulations may dictate the features and performance of enclosures for electrical equipment in hazardous areas, such as petrochemical plants or coal mines. Electronic packaging may place many demands on an enclosure for heat dissipation, radio frequency interference and electrostatic discharge protection, as well as functional, esthetic and commercial constraints.

The Fibre Channel electrical interface is one of two related Fibre Channel standards that can be used to physically interconnect computer devices. The other standard is a Fibre Channel optical interface, which is not covered in this article.

Cable management refers to management of electrical or optical cable in a cabinet or an installation. The term is used for products, workmanship or planning. Cables can easily become tangled, making them difficult to work with, sometimes resulting in devices accidentally becoming unplugged as one attempts to move a cable. Such cases are known as "cable spaghetti", and any kind of problem diagnosis and future updates to such enclosures could be very difficult.

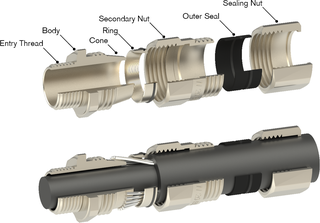

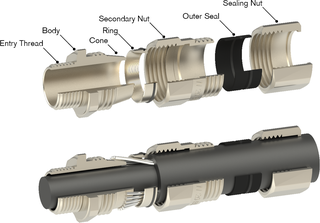

A cable gland is a device designed to attach and secure the end of an electrical cable to the equipment. A cable gland provides strain-relief and connects by a means suitable for the type and description of cable for which it is designed—including provision for making electrical connection to the armour or braid and lead or aluminium sheath of the cable, if any. Cable glands may also be used for sealing cables passing through bulkheads or gland plates. Cable glands are mostly used for cables with diameters between 1 mm and 75 mm.

The Stahlpanzerrohrgewinde standard for screw threads, more often called by the shortened Panzergewinde, was a technical standard created in Germany and subsequently used in Switzerland, Austria, and other neighboring European countries. It has been retracted. The thread is used to join pieces of electrical conduit and cable glands.

Roxtec is a company specialising in the development and manufacture of cable and pipe seals. Roxtec's products are designed to seal cable and pipe penetrations in order to protect from multiple hazards including fire, water, gas, dust, vibrations, electro-magnetic disturbances, vermin, and the risk of explosion. Markets include power, marine, oil and gas, telecoms, infrastructure, industrial equipment, and the process industries.

A cable grommet is a tube or ring through which an electrical cable passes. They are usually made of rubber or metal.

Electrical busbar systems are a modular approach to electrical wiring, where instead of a standard cable wiring to every single electrical device, the electrical devices are mounted onto an adapter which is directly fitted to a current carrying busbar. This modular approach is used in distribution boards, automation panels and other kinds of installation in an electrical enclosure.

A rugged smartphone is a specific type of toughened smartphone which is designed to be completely sealed within a durable housing to protect it against damage from water, shock, dust, and vibration. Rugged smartphones are designed to survive extreme weather and temperatures, accidental damage, and rough handling; making them ideal for working outdoors, or in harsh environments, along with use during extreme sports, such as sailing, rock climbing, etc. Most rugged smartphones have been tested to tough IP68 standards.