Related Research Articles

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource.

Incineration is a waste treatment process that involves the combustion of substances contained in waste materials. Industrial plants for waste incineration are commonly referred to as waste-to-energy facilities. Incineration and other high-temperature waste treatment systems are described as "thermal treatment". Incineration of waste materials converts the waste into ash, flue gas and heat. The ash is mostly formed by the inorganic constituents of the waste and may take the form of solid lumps or particulates carried by the flue gas. The flue gases must be cleaned of gaseous and particulate pollutants before they are dispersed into the atmosphere. In some cases, the heat that is generated by incineration can be used to generate electric power.

Slag is a by-product of smelting (pyrometallurgical) ores and recycled metals. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be classified as ferrous, ferroalloy or non-ferrous/base metals. Within these general categories, slags can be further categorized by their precursor and processing conditions. "Slag generated from the EAF process can contain toxic metals, which can be hazardous to human and environmental health".

CEMEX S.A.B. de C.V., known as Cemex, is a Mexican multinational building materials company headquartered in San Pedro, near Monterrey, Nuevo León, Mexico. It manufactures and distributes cement, ready-mix concrete and aggregates in more than 50 countries. In 2020 it was ranked as the 5th largest cement company in the world, at 87.09 million tonnes.

A waste-to-energy plant is a waste management facility that combusts wastes to produce electricity. This type of power plant is sometimes called a trash-to-energy, municipal waste incineration, energy recovery, or resource recovery plant.

Waste-to-energy (WtE) or energy-from-waste (EfW) is the process of generating energy in the form of electricity and/or heat from the primary treatment of waste, or the processing of waste into a fuel source. WtE is a form of energy recovery. Most WtE processes generate electricity and/or heat directly through combustion, or produce a combustible fuel commodity, such as methane, methanol, ethanol or synthetic fuels, often derived from the product syngas.

A mechanical biological treatment (MBT) system is a type of waste processing facility that combines a sorting facility with a form of biological treatment such as composting or anaerobic digestion. MBT plants are designed to process mixed household waste as well as commercial and industrial wastes.

The Energy Technologies Institute (ETI) was a public-private partnership between global energy and engineering companies and the UK Government that was established in the United Kingdom in 2007. The government set up the ETI following an announcement in the 2006 budget speech. The purpose of the ETI is to “accelerate the development, demonstration and eventual commercial deployment of a focused portfolio of energy technologies, which will increase energy efficiency, reduce greenhouse gas emissions and help achieve energy and climate change goals”. The institute works with a range of academic and commercial bodies.

South East London Combined Heat and Power, better known as SELCHP, is a major energy from waste incineration plant in Bermondsey, London. It was designed to generate both heat and electricity. The plant can generate up to 35 MegaWatts of power using a steam turbine in electricity only mode. It can incinerate up to 420,000 tonnes per year of municipal solid waste.

Incinerator bottom ash (IBA) is a form of ash produced in incineration facilities. This material is discharged from the moving grate of municipal solid waste incinerators. Once IBA is processed by removing contaminants, it can be used as an aggregate. Following processing, the material is termed IBA aggregate or processed IBA. The aggregate uses include:

Hempcrete or hemplime is biocomposite material, a mixture of hemp hurds (shives) and lime, sand, or pozzolans, which is used as a material for construction and insulation. It is marketed under names like Hempcrete, Canobiote, Canosmose, Isochanvre and IsoHemp. Hempcrete is easier to work with than traditional lime mixes and acts as an insulator and moisture regulator. It lacks the brittleness of concrete and consequently does not need expansion joints.

Enhanced weathering, also termed ocean alkalinity enhancement when proposed for carbon credit systems, is a process that aims to accelerate the natural weathering by spreading finely ground silicate rock, such as basalt, onto surfaces which speeds up chemical reactions between rocks, water, and air. It also removes carbon dioxide from the atmosphere, permanently storing it in solid carbonate minerals or ocean alkalinity. The latter also slows ocean acidification.

The environmental impact of concrete, its manufacture, and its applications, are complex, driven in part by direct impacts of construction and infrastructure, as well as by CO2 emissions; between 4-8% of total global CO2 emissions come from concrete. Many depend on circumstances. A major component is cement, which has its own environmental and social impacts and contributes largely to those of concrete.

The North East of England Process Industry Cluster (NEPIC) is an economic cluster developed in accordance with Michael Porter's theories and strategies regarding industrial clusters. The chemistry-using sectors in North East England, where more than 1,400 businesses are headquartered in the industry's supply chain, formed this Process Industry Cluster. In the north-east of England, the industry employs approximately 35,000 direct workers and around 190,000 indirect workers, who collectively account for more than one-third of the area's industrial economy. Companies in the cluster produce 35% of the pharmaceuticals and 50% of the petrochemicals used in the UK, making this area the only net exporter of goods from the country. The area has more than £13 billion in exports.

Chinook Sciences is a US and UK based technology company that specializes in waste to energy and metal recovery.

Stefaan J. R. Simons is a chemical engineer and senior academic employed by the University College London. In 2012, he was appointed Director of the International Energy Policy Institute (IEPI) and the inaugural BHP Billiton Chair of Energy Policy at UCL Australia. Prior to moving to Australia, Simons established the School of Engineering at Nazarbayev University in Kazakhstan-– the world's largest producer of uranium. Simons' work has been published in over 200 journals, books and conference proceedings.

The Lakeside EfW is located in Colnbrook, Slough. It incinerates residual waste, and since 2010 it has also been authorised to incinerate low-level radioactive waste.

First Milk is a dairy cooperative in Britain which manufactures cheese, specialist dairy ingredients and whey proteins for its customers, as well as providing traceable fresh milk to a range of dairy manufacturers and food processors. As a dairy co-operative, owned and run by farmers; the area covered by its milk pool runs from the Mull of Kintyre in Scotland down through England and Wales.

Tradebe is a waste management company based in Barcelona that was established in 1980. It operates in Spain, France, the United Kingdom, the United States and Oman. The chairman is Josep Creixell, and the Chief Executive is Victor Creixell.

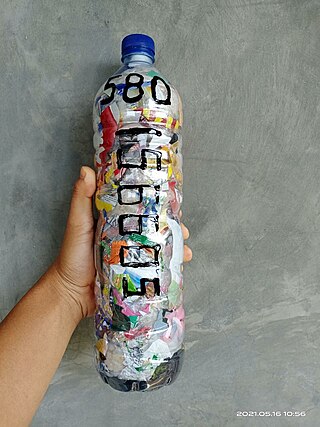

Plastic sequestration is a means of plastic waste management that secures used plastic out of industry and out of the environment into reusable building blocks made by manual compaction. Plastic sequestration is motivated by environmental protection and modeled on the Earth's process of carbon sequestration. Emerging out of the struggle of towns and communities in the Global South to deal with plastic pollution, plastic sequestration compaction methods are characterized by being locally based, non-capital, non-industrial and low-tech. Plastic sequestration is defined by the goals of securing plastic out of the environment and out of high energy/carbon industrial systems. Based on eliminating the chemical and physical and abiotic and biotic degradation pathways, plastic sequestration aims to achieve these goals, by terminally reducing the net surface area of thin film plastics. The building blocks that emerge from plastic sequestration are used in applications that further protect from degradation and permanently keep plastic out of industrial processes, thereby preventing their carbon emissions.

References

- ↑ "Our Process". c8a.co.uk. Retrieved 2015-06-02.

- ↑ "University's 'green' invention to treat waste materials goes into commercial production | Engineering & Science | University of Greenwich". www2.gre.ac.uk. Archived from the original on 2015-06-02. Retrieved 2015-06-02.

- ↑ "Treating waste with carbon dioxide - Case Studies - University of Greenwich Business and Enterprise". enterprise.gre.ac.uk. University of Greenwich. Archived from the original on 2016-03-04. Retrieved 2015-06-03.

- ↑ "Carbon8 - Case Studies - University of Greenwich Business and Enterprise". enterprise.gre.ac.uk. University of Greenwich. Archived from the original on 2015-05-03. Retrieved 2015-06-03.

- ↑ "Carbon 8 - WRc". www.wrcplc.co.uk. Retrieved 2015-06-02.

- ↑ "University's 'green' invention to treat waste materials goes into commercial production | Engineering & Science | University of Greenwich". www2.gre.ac.uk. Archived from the original on 2015-06-02. Retrieved 2015-06-02.

- ↑ Grozdanic, Lidija. "World's First Carbon Negative Building Block Unveiled in the UK" . Retrieved 2015-06-02.

- ↑ "Carbon 8 - WRc". www.wrcplc.co.uk. Retrieved 2015-06-02.

- ↑ "Grundon Invests Further Millions In Carbon8 Aggregates". Archived from the original on 2015-06-02. Retrieved 2015-06-02.

- ↑ "Green Light For New Carbon8 Plant At Avonmouth". Archived from the original on 2015-06-02. Retrieved 2015-06-02.