Containerization is a system of intermodal freight transport using intermodal containers. Containerization, also referred as container stuffing or container loading, is the process of unitization of cargoes in exports. Containerization is the predominant form of unitization of export cargoes today, as opposed to other systems such as the barge system or palletization. The containers have standardized dimensions. They can be loaded and unloaded, stacked, transported efficiently over long distances, and transferred from one mode of transport to another—container ships, rail transport flatcars, and semi-trailer trucks—without being opened. The handling system is mechanized so that all handling is done with cranes and special forklift trucks. All containers are numbered and tracked using computerized systems.

A container ship is a cargo ship that carries all of its load in truck-size intermodal containers, in a technique called containerization. Container ships are a common means of commercial intermodal freight transport and now carry most seagoing non-bulk cargo.

Intermodal freight transport involves the transportation of freight in an intermodal container or vehicle, using multiple modes of transportation, without any handling of the freight itself when changing modes. The method reduces cargo handling, and so improves security, reduces damage and loss, and allows freight to be transported faster. Reduced costs over road trucking is the key benefit for inter-continental use. This may be offset by reduced timings for road transport over shorter distances.

In transportation, freight refers to goods conveyed by land, water or air, while cargo refers specifically to freight when conveyed via water or air. In economics, freight refers to goods transported at a freight rate for commercial gain. The term cargo is also used in case of goods in the cold-chain, because the perishable inventory is always in transit towards a final end-use, even when it is held in cold storage or other similar climate-controlled facilities, including warehouses.

Transshipment, trans-shipment or transhipment is the shipment of goods or containers to an intermediate destination, then to another destination.

A dockworker is a waterfront manual laborer who loads and unloads ships.

A merchant ship, merchant vessel, trading vessel, or merchantman is a watercraft that transports cargo or carries passengers for hire. This is in contrast to pleasure craft, which are used for personal recreation, and naval ships, which are used for military purposes.

A bulk carrier or bulker is a merchant ship specially designed to transport unpackaged bulk cargo—such as grain, coal, ore, steel coils, and cement—in its cargo holds. Since the first specialized bulk carrier was built in 1852, economic forces have led to increased size and sophistication of these ships. Today's bulk carriers are specially designed to maximize capacity, safety, efficiency, and durability.

A dry bulk cargo barge is a barge designed to carry freight such as coal, ores, grain, sand or gravel, or similar materials. Barges are usually constructed of steel. They have an outer hull, and one or more internal holds. A rake barge has a bow shaped to cause less resistance when being pushed and is usually placed at the head of the tow. A box barge has no rake to the ends and is usually placed in the center and rear of the tow and can hold more cargo.

The lighter aboard ship (LASH) system refers to the practice of loading barges (lighters) aboard a bigger vessel for transport. It was developed in response to a need to transport lighters, a type of unpowered barge, between inland waterways separated by open seas. Lighters are typically towed or pushed around harbors, canals or rivers and cannot be relocated under their own power. The carrier ships are known variously as LASH carriers, barge carriers, kangaroo ships or lighter transport ships.

A ship's hold or cargo hold is a space for carrying cargo in the ship's compartment.

A gantry crane is a crane built atop a gantry, which is a structure used to straddle an object or workspace. They can range from enormous "full" gantry cranes, capable of lifting some of the heaviest loads in the world, to small shop cranes, used for tasks such as lifting automobile engines out of vehicles. They are also called portal cranes, the "portal" being the empty space straddled by the gantry.

The Port of Ashdod is one of Israel's three main cargo ports. The port is located in Ashdod, about 40 kilometers south of Tel Aviv, adjoining the mouth of the Lachish River. Its establishment significantly enhanced the country's port capacity. It handles the largest volume of cargo containers annually of all Israeli ports. Ships carrying humanitarian aid for the Gaza Strip also unload their cargo at Ashdod.

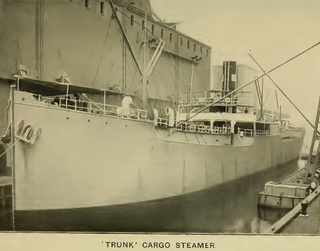

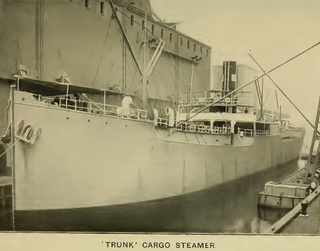

A trunk deck ship is a type of merchant ship with a hull that was stepped inward in order to obtain more favourable treatment under canal toll rules then in effect. As those tolls were set by net tonnage, a measure of volume, and as the tonnage rules did not account for all of the cargo space of such vessels, trunk deck ships incurred lower tolls than more conventional ships of equivalent capacity. When the measurement rules were changed, this ship type was no longer built.

In shipping, break-bulk, breakbulk, or break bulk cargo, also called general cargo, is goods that are stowed on board ships in individually counted units. Traditionally, the large numbers of items are recorded on distinct bills of lading that list them by different commodities. This is in contrast to cargo stowed in modern intermodal containers as well as bulk cargo, which goes directly, unpackaged and in large quantities, into a ship's hold(s), measured by volume or weight.

A shiploader is a large machine used for continuously loading bulk solid materials such as iron ore, coal, fertilizers, grains and/or material in bags onto ships or barges. These machines are located in ports and jetties to facilitate bulk material exportation. Generally shiploaders are engineered to suit specific project requirements. Those requirements often include: port design, material characteristics, loading capacity, vessel type, local law, and budgetary limitations. A shiploader mainly consists of a central column, an extendable arm or boom, a belt conveyor extending out of the boom structure, a slewing mechanism, and a loading chute to transfer product from a source conveyor or feeder. The boom can move front and back, up and down by separate drives so that it can fill the whole breadth of the ship hold and adapt to the ships increasing draught while it is loaded.

Open Hatch General Cargo, abbreviated (OHGC), is a ship designed to transport forest products, bulk cargos, unitized cargoes, project cargoes and containers.

The MACS3 Loading Computer System is a computer controlled loading system for commercial vessels, developed by Navis Carrier & Vessel Solutions. Prior to October, 2017 it was offered by Interschalt maritime systems GmbH, and before 2007 - by Seacos Computersysteme & Software GmbH.

Stowage plan for container ships or bay plan is the plan and method by which different types of container vessels are loaded with containers of specific standard sizes. The plans are used to maximize the economy of shipping and safety on board.

Container port design process is a set of correlated practices considered during container port design, aiming to transfer general business mission into detailed design documents for future construction and operation.