Concrete is a composite material composed of aggregate bonded together with a fluid cement that cures to a solid over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminium combined.

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource.

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and is usually made from limestone. It is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker, and then grinding the clinker with the addition of several percent gypsum. Several types of portland cement are available. The most common, historically called ordinary portland cement (OPC), is grey, but white portland cement is also available. Its name is derived from its resemblance to Portland stone which is quarried on the Isle of Portland in Dorset, England. It was named by Joseph Aspdin who obtained a patent for it in 1824. His son William Aspdin is regarded as the inventor of "modern" portland cement due to his developments in the 1840s.

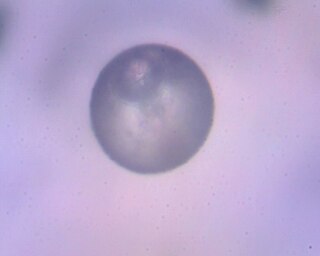

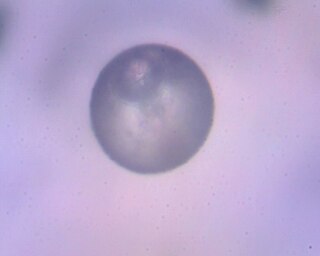

A cenosphere or kenosphere is a lightweight, inert, hollow sphere made largely of silica and alumina and filled with air or inert gas, typically produced as a coal combustion byproduct at thermal power plants. The color of cenospheres varies from gray to almost white and their density is about 0.4–0.8 g/cm3 (0.014–0.029 lb/cu in), which gives them a great buoyancy.

Silica fume, also known as microsilica, is an amorphous (non-crystalline) polymorph of silicon dioxide, silica. It is an ultrafine powder collected as a by-product of the silicon and ferrosilicon alloy production and consists of spherical particles with an average particle diameter of 150 nm. The main field of application is as pozzolanic material for high performance concrete.

Air entrainment in concrete is the intentional creation of tiny air bubbles in a batch by adding an air entraining agent during mixing. A form of surfactant it allows bubbles of a desired size to form. These are created during concrete mixing, with most surviving to remain part of it when hardened.

Concrete recycling is the use of rubble from demolished concrete structures. Recycling is cheaper and more ecological than trucking rubble to a landfill. Crushed rubble can be used for road gravel, revetments, retaining walls, landscaping gravel, or raw material for new concrete. Large pieces can be used as bricks or slabs, or incorporated with new concrete into structures, a material called urbanite.

Metakaolin is the anhydrous calcined form of the clay mineral kaolinite. Rocks that are rich in kaolinite are known as china clay or kaolin, traditionally used in the manufacture of porcelain. The particle size of metakaolin is smaller than cement particles, but not as fine as silica fume.

Pozzolans are a broad class of siliceous and aluminous materials which, in themselves, possess little or no cementitious value but which will, in finely divided form and in the presence of water, react chemically with calcium hydroxide (Ca(OH)2) at ordinary temperature to form compounds possessing cementitious properties. The quantification of the capacity of a pozzolan to react with calcium hydroxide and water is given by measuring its pozzolanic activity. Pozzolana are naturally occurring pozzolans of volcanic origin.

Cement clinker is a solid material produced in the manufacture of portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres (0.12 in) to 25 millimetres (0.98 in) in diameter. It is produced by sintering limestone and aluminosilicate materials such as clay during the cement kiln stage.

Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls:

A geopolymer is a vague pseudo-chemical term used to describe inorganic, typically bulk ceramic-like material that forms covalently bonded, non-crystalline (amorphous) networks, often intermingled with other phases. Many geopolymers may also be classified as alkali-activated cements or acid-activated binders. They are mainly produced by a chemical reaction between a chemically reactive aluminosilicate powder e.g. metakaolin or other clay-derived powders, natural pozzolan, or suitable glasses, and an aqueous solution that causes this powder to react and re-form into a solid monolith. The most common pathway to produce geopolymers is by the reaction of metakaolin with sodium silicate, which is an alkaline solution, but other processes are also possible.

Foam Index test is a rapid method to determine the relative levels of Air Entraining Agent (AEA) needed during concrete mixing, with or without mineral additives like combustion fly ash, that control air void volumes within cured concrete.

Roman concrete, also called opus caementicium, was used in construction in ancient Rome. Like its modern equivalent, Roman concrete was based on a hydraulic-setting cement added to an aggregate.

Concrete is produced in a variety of compositions, finishes and performance characteristics to meet a wide range of needs.

Mulalo Doyoyo was a South African engineer, inventor, and professor.

Sulfur concrete, sometimes named thioconcrete or sulfurcrete, is a composite construction material, composed mainly of sulfur and aggregate. Cement and water, important compounds in normal concrete, are not part of sulfur concrete. The concrete is heated above the melting point of elemental sulfur at ca. 140 °C (284 °F) in a ratio of between 12% and 25% sulfur, the rest being aggregate.

The environmental impact of concrete, its manufacture, and its applications, are complex, driven in part by direct impacts of construction and infrastructure, as well as by CO2 emissions; between 4-8% of total global CO2 emissions come from concrete. Many depend on circumstances. A major component is cement, which has its own environmental and social impacts and contributes largely to those of concrete.

Energetically modified cements (EMCs) are a class of cements made from pozzolans, silica sand, blast furnace slag, or Portland cement. The term "energetically modified" arises by virtue of the mechanochemistry process applied to the raw material, more accurately classified as "high energy ball milling" (HEBM). At its simplest this means a milling method that invokes high kinetics by subjecting "powders to the repeated action of hitting balls" as compared to (say) the low kinetics of rotating ball mills. This causes, amongst others, a thermodynamic transformation in the material to increase its chemical reactivity. For EMCs, the HEBM process used is a unique form of specialised vibratory milling discovered in Sweden and applied only to cementitious materials, here called "EMC Activation".

Foam concrete, also known as Lightweight Cellular Concrete (LCC) and Low Density Cellular Concrete (LDCC), and by other names, is defined as a cement-based slurry, with a minimum of 20% foam entrained into the plastic mortar. As mostly no coarse aggregate is used for production of foam concrete the correct term would be called mortar instead of concrete; it may be called "foamed cement" as well. The density of foam concrete usually varies from 400 kg/m3 to 1600 kg/m3. The density is normally controlled by substituting all or part of the fine aggregate with the foam.