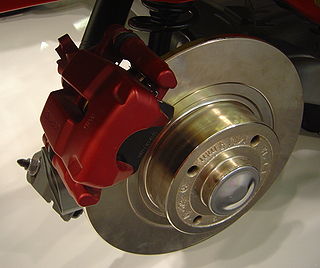

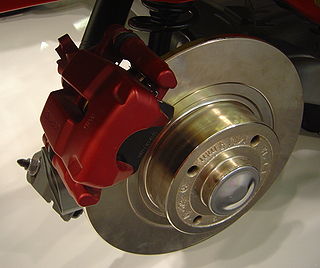

A disc brake is a type of brake that uses the calipers to squeeze pairs of pads against a disc or a rotor to create friction. There are two basic types of brake pad friction mechanisms: abrasive friction and adherent friction. This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to hold it stationary. The energy of motion is converted into heat, which must be dissipated to the environment.

A wetsuit is a garment worn to provide thermal protection while wet. It is usually made of foamed neoprene, and is worn by surfers, divers, windsurfers, canoeists, and others engaged in water sports and other activities in or on the water. Its purpose is to provide thermal insulation and protection from abrasion, ultraviolet exposure, and stings from marine organisms. It also contributes extra buoyancy. The insulation properties of neoprene foam depend mainly on bubbles of gas enclosed within the material, which reduce its ability to conduct heat. The bubbles also give the wetsuit a low density, providing buoyancy in water.

There are many types of car body styles. They vary depending on intended use, market position, location, and the era they were made.

Shrink wrap, also shrink film, is a material made up of polymer plastic film. When heat is applied, it shrinks tightly over whatever it is covering. Heat can be applied with a handheld heat gun, or the product and film can pass through a heat tunnel on a conveyor.

A custom car is a passenger vehicle that has been altered to improve its performance, change its aesthetics, or combine both. Some automotive enthusiasts in the United States want to push "styling and performance a step beyond the showroom floor - to truly craft an automobile of one's own." A custom car in British usage, according to Collins English Dictionary, is built to the buyer's own specifications.

Bondo is a polyester putty product originally marketed as an automotive body filler. Nowadays the brand name is used by 3M for a line of American-made products for automotive, marine and household repairs. The term Bondo is trademarked by 3M, but is commonly used to refer to any brand of automotive repair putty due to its popularity. It is also used by sculptors.

The pillars on a car with permanent roof body style are the vertical or nearly vertical supports of its window area or greenhouse—designated respectively as the A, B, C and D-pillar, moving from front to rear, in profile view.

A subframe is a structural component of a vehicle, such as an automobile or an aircraft, that uses a discrete, separate structure within a larger body-on-frame or unibody to carry specific components like the powertrain, drivetrain, and suspension. The subframe is typically bolted or welded to the vehicle. When bolted, it often includes rubber bushings or springs to dampen vibrations.

The English wheel, in Britain also known as a wheeling machine, is a metalworking tool that enables a craftsperson to form compound curves from flat sheets of metal such as aluminium or steel.

Aptera Motors Corp. is an American crowd funded, pre-production startup company based in Carlsbad, California. It was founded in 2005 before liquidating in 2011. The company was relaunched by the original founders in 2019.

Fender is the American English term for the part of an automobile, motorcycle or other vehicle body that frames a wheel well. Its primary purpose is to prevent sand, mud, rocks, liquids, and other road spray from being thrown into the air by the rotating tire. Fenders are typically rigid and can be damaged by contact with the road surface.

The fifth-generation Chevrolet Camaro is a pony car that was manufactured by American automobile manufacturer Chevrolet from 2010 to 2015 model years. It is the fifth distinct generation of the muscle/pony car to be produced since its original introduction in 1967. Production of the fifth generation model began on March 16, 2009 after several years on hiatus since the previous generation's production ended in 2002 and went on sale to the public in April 2009 for the 2010 model year.

A vehicle frame, also historically known as its chassis, is the main supporting structure of a motor vehicle to which all other components are attached, comparable to the skeleton of an organism.

Paintless dent repair (PDR), also known as paintless dent removal, describes a method of removing small dents, dings, and minor collision damage dents from the body of a motor vehicle. A wide range of damage can be repaired using paintless dent repair as long as the paint surface is intact. Paintless dent repair may be used on both aluminum and steel panels.

A solar car is a solar vehicle for use on public roads or race tracks. Solar vehicles are electric vehicles that use self-contained solar cells to provide full or partial power to the vehicle via sunlight. Solar vehicles typically contain a rechargeable battery to help regulate and store the energy from the solar cells and from regenerative braking. Some solar cars can be plugged into external power sources to supplement the power of sunlight used to charge their battery.

Toyota Concept Vehicles produced between 1990 and 1999 include:

Electric rickshaws are small three-wheeled vehicles powered by an electric battery and motor. These small electric vehicles do not require petroleum fuel like auto rickshaws but still offer greater mobility than traditional pulled rickshaws. This has led to their popularity and use expanding in some cities since 2008. Electric rickshaws are primarily manufactured in India, Bangladesh, Nepal, and China.

Roadkill is an automotive-themed internet show produced by the MotorTrend Group. It is hosted by former Hot Rod Magazine editor David Freiburger and former technical staff editor Mike Finnegan. Roadkill is primarily filmed in Southern California, with other episodes taking place across the United States, Canada and Australia.

Hot shrinking is a process in car bodyworks. As the name suggests, heat will be involved, while "shrinking" is the process of straightening a metal section. This is a method of panel beating where a panel is first heated to make it softer. In most cases, heating will be done by use of the oxyacetylene flame.

Styling Garage was a coachbuilder and tuner near Hamburg, Germany, which operated from 1979 until 1986. SGS made extravagant and expensive designs, mainly based on the Mercedes-Benz W126 (S-class). More than half of their buyers came from the Arab world, with the remainder consisting mostly of American celebrities, Japanese businessmen, and African leaders.