Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns.

A printed circuit board (PCB) or printed wiring board (PWB) is a laminated sandwich structure of conductive and insulating layers. PCBs have two complementary functions. The first is to affix electronic components in designated locations on the outer layers by means of soldering. The second is to provide reliable electrical connections between the component's terminals in a controlled manner often referred to as PCB design. Each of the conductive layers is designed with an artwork pattern of conductors that provides electrical connections on that conductive layer. Another manufacturing process adds vias, plated-through holes that allow interconnections between layers.

A composite material is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions.

Fiberglass or fibreglass is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic.

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called epoxy. The IUPAC name for an epoxide group is an oxirane.

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure, or mixing with a catalyst. Heat is not necessarily applied externally, but is often generated by the reaction of the resin with a curing agent. Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a permanently assembled object created using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used.

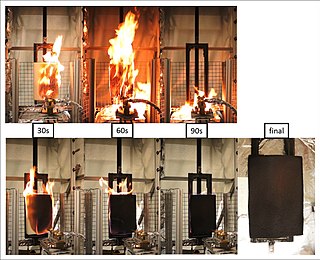

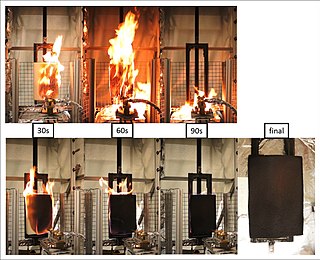

FR-4 is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing).

The term flame retardants subsumes a diverse group of chemicals which are added to manufactured materials, such as plastics and textiles, and surface finishes and coatings. Flame retardants are activated by the presence of an ignition source and are intended to prevent or slow the further development of ignition by a variety of different physical and chemical methods. They may be added as a copolymer during the polymerisation process, or later added to the polymer at a moulding or extrusion process or applied as a topical finish. Mineral flame retardants are typically additive while organohalogen and organophosphorus compounds can be either reactive or additive.

Fibre-reinforced plastic is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass, carbon, aramid, or basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use.

Micarta is a brand name for composites of linen, canvas, paper, fiberglass, carbon fiber, or other fabric in a thermosetting plastic. It was originally used in electrical and decorative applications. Micarta was developed by George Westinghouse at least as early as 1910 using phenolic resins invented by Leo Baekeland. These resins were used to impregnate paper and cotton fabric which were cured under pressure and high temperature to produce laminates. In later years this manufacturing method included the use of fiberglass fabric and other resin types were also used. Today Micarta high-pressure industrial laminates are produced with a wide variety of resins and fibers. The term has been used generically for most resin impregnated fiber compounds. Common uses of modern high-pressure laminates are as electrical insulators, printed circuit board substrates, and knife handles.

Chlorendic acid, or 1,4,5,6,7,7-hexachlorobicyclo[2.2.1]-hept-5-ene-2,3-dicarboxylic acid, is a chlorinated hydrocarbon used in the synthesis of some flame retardants and polymers. It is a common breakdown product of several organochlorine insecticides.

Nonwoven fabric is a fabric-like material made from staple fibre (short) and long fibres, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam.

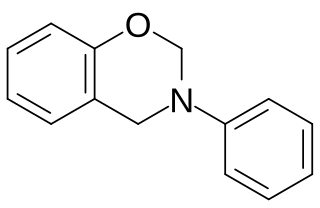

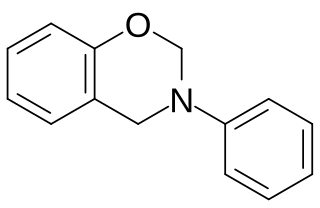

Polybenzoxazines, also called benzoxazine resins, are cured polymerization products derived from benzoxazine monomers.

Building insulation materials are the building materials which form the thermal envelope of a building or otherwise reduce heat transfer.

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as glass-reinforced plastic radar domes on aircraft and graphite-epoxy payload bay doors on the Space Shuttle.

Carbon fiber-reinforced polymers, carbon-fibre-reinforced polymers, carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic, also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications.

A stamped circuit board (SCB) is used to mechanically support and electrically connect electronic components using conductive pathways, tracks or traces etched from copper sheets laminated onto a non-conductive substrate. This technology is used for small circuits, for instance in the production of LEDs.

Aluminium diethyl phosphinate is a chemical compound with formula Al(C

4H

10O

2P)3. It decomposes above 300 °C.

G-10 is a high-pressure fiberglass laminate, a type of composite material. It is created by stacking multiple layers of glass cloth, soaked in epoxy resin, and by compressing the resulting material under heat until the epoxy cures. It is manufactured in flat sheets, most often a few millimeters thick.