The copying lathe or duplicating lathe is a lathe that creates shapes identical to the specified pattern.

The copying lathe or duplicating lathe is a lathe that creates shapes identical to the specified pattern.

In early 1700s Russian engineer Andrey Nartov invented a copying lathe for the purpose of ornamental turning, which allowed the operator to make ornaments with the same precision as that of handicraft work of that time. [1] The Hermitage Museum, Russia, displays the Nartov's copying lathe used for ornamental turning: making medals and guilloche patterns designed by Nartov in 1721. [2] Nartov's lathe duplicated the pattern from a template to a blank, cutting to the preset scale. A probe traced the template and the cutter cut accordingly. The cutter was set on the same axis as the probe, but was controlled by the screw with the smaller step, which ensured the scaling. It could cut minute detail, but worked very slowly. The duplicating lathe, as well as other machinery of Nartov's invention was described, with diagrams, in Nartov's unpublished manuscript, Theatrum Machinarium. It was found and published, in Russian and English, in 1960s. [1]

The Blanchard lathe, invented by Thomas Blanchard, revolutionized the process of gun stock making in the 1820s, after it was invented. [3] Blanchard's copying lathe traced a model to turn gun stocks, producing the desired contour automatically. [4] Originally used for gun stocks, it was subsequently used for numerous objects of irregular shape: piano legs, wig stands, shoe lasts, etc. In Blanshard's copying lathe a rotating template controlled the cutter which cut the blank rotated in unison with the pattern, while the pattern tracer and the cutter moved along the horizontal axis. [5]

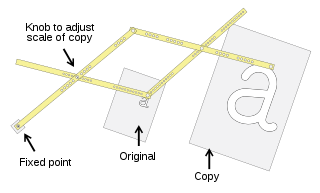

A pantograph is a mechanical linkage connected in a manner based on parallelograms so that the movement of one pen, in tracing an image, produces identical movements in a second pen. If a line drawing is traced by the first point, an identical, enlarged, or miniaturized copy will be drawn by a pen fixed to the other. Using the same principle, different kinds of pantographs are used for other forms of duplication in areas such as sculpting, minting, engraving, and milling.

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path. The cam can be a simple tooth, as is used to deliver pulses of power to a steam hammer, for example, or an eccentric disc or other shape that produces a smooth reciprocating motion in the follower, which is a lever making contact with the cam. A cam timer is similar, and were widely used for electric machine control before the advent of inexpensive electronics, microcontrollers, integrated circuits, programmable logic controllers and digital control.

A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material.

Machining is a process in which a material is cut to a desired final shape and size by a controlled material-removal process. The methods that have this common theme are collectively called subtractive manufacturing, which utilizes machine tools, in contrast to additive manufacturing, which uses controlled addition of material.

Guilloché is a decorative technique in which a very precise, intricate and repetitive pattern is mechanically engraved into an underlying material via engine turning, which uses a machine of the same name, also called a rose engine lathe. This mechanical technique improved on more time-consuming designs achieved by hand and allowed for greater delicacy, precision, and closeness of line, as well as greater speed.

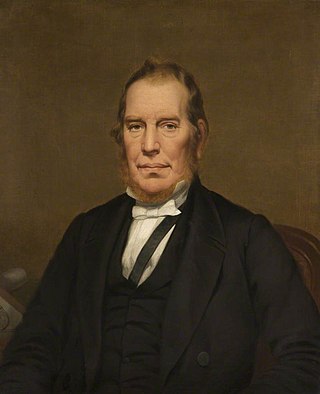

Richard Roberts was a Welsh patternmaker and engineer whose development of high-precision machine tools contributed to the birth of production engineering and mass production.

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a mechanism that can generate a variety of forms. The operator is known as a turner, and the skills needed to use the tools were traditionally known as turnery. In pre-industrial England, these skills were sufficiently difficult to be known as "the mysteries of the turners' guild." The skills to use the tools by hand, without a fixed point of contact with the wood, distinguish woodturning and the wood lathe from the machinist's lathe, or metal-working lathe.

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by more-specific subtype names. These rigid machine tools remove material from a rotating workpiece via the movements of various cutting tools, such as tool bits and drill bits.

A rose engine lathe is a specialized kind of geometric lathe. The head stock rocks back and forth with a rocking motion and/or slides along the spindle axis in a pumping motion. A rosette or cam-like pattern mounted on the spindle is controlled by moving against a cam follower(s) while the lathe spindle rotates. Rose engine work can make flower patterns, as well as convoluted, symmetrical, multi-lobed geometric patterns. The patterns it produces are similar to that of a Spirograph, in metal. No other ornamental lathe can produce these "rose" patterns. The decoration produced by a rose engine lathe is called guilloche. It sometimes confused with "jewel finishes" or engine turning, a much cheaper process of making swirly marks in metal by a rotating abrasive peg or pad, which is repeatedly applied to the surface to make a pattern of overlapping circles. Jewel finishes used to be common on stereo faceplates and automobile interiors.

In machining, boring is the process of enlarging a hole that has already been drilled by means of a single-point cutting tool, such as in boring a gun barrel or an engine cylinder. Boring is used to achieve greater accuracy of the diameter of a hole, and can be used to cut a tapered hole. Boring can be viewed as the internal-diameter counterpart to turning, which cuts external diameters.

A turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable. It evolved from earlier lathes with the addition of the turret, which is an indexable toolholder that allows multiple cutting operations to be performed, each with a different cutting tool, in easy, rapid succession, with no need for the operator to perform set-up tasks in between or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in jig-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via digitally-directed servomechanisms for computer numerical control lathes.

Thomas Blanchard was an American inventor who lived much of his life in Springfield, Massachusetts, where in 1819, he pioneered the assembly line style of mass production in America, and also invented the first machining lathe for interchangeable parts. Blanchard worked, for much of his career, with the Springfield Armory. In 1825, Blanchard also invented America's first car, which he called a "horseless carriage," powered by steam. During Blanchard's lifetime, he was awarded over twenty-five patents for his creations.

David Wilkinson was a U.S. mechanical engineer who invented a lathe for cutting screw threads, which was extremely important in the development of the machine tool industry in the early 19th century.

In manufacturing, threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. There are many methods of generating threads, including subtractive methods ; deformative or transformative methods ; additive methods ; or combinations thereof.

Andrey Konstantinovich Nartov (1683—1756) was a Russian scientist, military engineer, inventor and sculptor. He was a personal craftsman of Peter I of Russia, and later a member of the Russian Academy of Science.

Ornamental turning is a type of turning, a craft that involves cutting of a work mounted in a lathe. The work can be made of any material that is suitable for being cut in this way, such as wood, bone, ivory or metal. Plain turning is work executed on a lathe where a transverse section through any part of the work comprises a plain circle. Ornamental turning, also called Complex turning, is executed on a lathe with attachments which convert that plain circular section to variants of outline; these range from a simple series of cuts taken at intervals around the work to non-circular movements whereby the whole of the circular shape is removed to give a completely different form. Such shapes are achieved by various means, the principal ones being:

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances.

Key duplication refers to the process of creating a key based on an existing key. Key cutting is the primary method of key duplication: a flat key is fitted into a vise in a machine, with a blank attached to a parallel vise, and the original key is moved along a guide, while the blank is moved against a blade, which cuts it. After cutting, the new key is deburred: scrubbed with a wire brush, either built into the machine, or in a bench grinder, to remove burrs which, were they not removed, would be dangerously sharp and, further, foul locks.