A threshing machine or a thresher is a piece of farm equipment that separates grain seed from the stalks and husks. It does so by beating the plant to make the seeds fall out. Before such machines were developed, threshing was done by hand with flails: such hand threshing was very laborious and time-consuming, taking about one-quarter of agricultural labour by the 18th century. Mechanization of this process removed a substantial amount of drudgery from farm labour. The first threshing machine was invented circa 1786 by the Scottish engineer Andrew Meikle, and the subsequent adoption of such machines was one of the earlier examples of the mechanization of agriculture. During the 19th century, threshers and mechanical reapers and reaper-binders gradually became widespread and made grain production much less laborious.

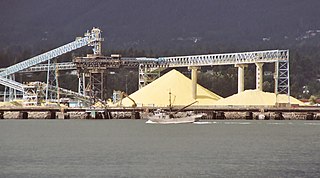

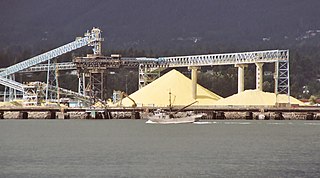

A conveyor belt is the carrying medium of a belt conveyor system. A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys, with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more.

The modern combine harvester, also called a combine, is a machine designed to harvest a variety of cultivated seeds. Combine harvesters are one of the most economically important labour-saving inventions, significantly reducing the fraction of the population engaged in agriculture. Among the crops harvested with a combine are wheat, rice, oats, rye, barley, corn (maize), sorghum, millet, soybeans, flax (linseed), sunflowers and rapeseed. The separated straw is then either chopped onto the field and ploughed back in, or laid out in rows, ready to be baled and used for bedding and cattle feed.

A reaper is a farm implement or person that reaps crops at harvest when they are ripe. Usually the crop involved is a cereal grass. The first documented reaping machines were Gallic reapers that were used in Roman times in what would become modern-day France. The Gallic reaper involved a comb which collected the heads, with an operator knocking the grain into a box for later threshing.

A forage harvester – also known as a silage harvester, forager or chopper – is a farm implement that harvests forage plants to make silage. Silage is grass, corn or hay, which has been chopped into small pieces, and compacted together in a storage silo, silage bunker, or in silage bags. It is then fermented to provide feed for livestock. Haylage is a similar process to silage but using grass which has dried.

Threshing or thrashing is the process of loosening the edible part of grain from the straw to which it is attached. It is the step in grain preparation after reaping. Threshing does not remove the bran from the grain.

A bucket-wheel excavator (BWE) is a large heavy equipment machine used in surface mining.

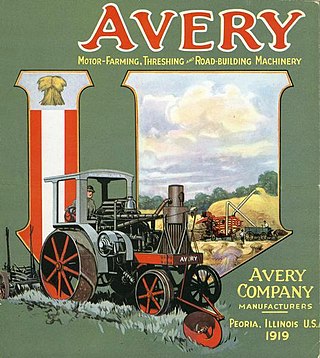

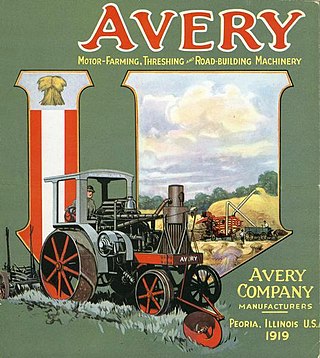

The Avery Company, founded by Robert Hanneman Avery, was an American farm tractor manufacturer famed for its undermounted engine which resembled a railroad engine more than a conventional farm steam engine. Avery founded the farm implement business after the Civil War. His company built a large line of products, including steam engines, beginning in 1891. The company started with a return flue design and later adapted the undermount style, including a bulldog design on the smokebox door. Their design was well received by farmers in central Illinois. They expanded their market nationwide and overseas until the 1920s, when they failed to innovate and the company faltered. They manufactured trucks for a period of time, and then automobiles. until they finally succumbed to an agricultural crisis and the Depression.

Intensive crop farming is a modern industrialized form of crop farming. Intensive crop farming's methods include innovation in agricultural machinery, farming methods, genetic engineering technology, techniques for achieving economies of scale in production, the creation of new markets for consumption, patent protection of genetic information, and global trade. These methods are widespread in developed nations.

A checkweigher is an automatic or manual machine for checking the weight of packaged commodities. It is normally found at the offgoing end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Any packs that are outside the tolerance are taken out of line automatically.

A bean harvester, also known as a bean thresher or bean combine, is a threshing machine which is used to harvest beans. It mainly consists of a pickup, several beaters, shakers, one or several fans, elevators, conveyor belts, a storage bin, and usually a spreader at the rear. Until recently, the only practical manufacturer of bean harvesters was The Bidwell Bean Thresher Company.

Maize, also known as corn in North American English, is a tall stout grass that produces cereal grain. It was domesticated by indigenous peoples in southern Mexico about 9,000 years ago from wild teosinte. Native Americans planted it alongside beans and squashes in the Three Sisters polyculture. The leafy stalk of the plant gives rise to male inflorescences or tassels which produce pollen, and female inflorescences called ears. The ears yield grain, known as kernels or seeds. In modern commercial varieties, these are usually yellow or white; other varieties can be of many colors.

The All-Crop harvester or All-Crop combine was a tractor-drawn, PTO-driven combine harvesters made by Allis-Chalmers from the mid-1930s to the early 1960s. Aside from small grains, these harvesters were able to harvest some flowers, as well as various grasses and legume crops for seed.

Grain damage is any degradation in the quality of grain. In the current grain trade, this damage can affect price, feed quality, food product quality, and susceptibility to pest contamination. Between the field and the end use, grain may go through any number of handling operations which can each contribute to grain damage. For example, grain might encounter free fall, conveyors, spouts, grain throwers, elevators, hoppers, dryers, and many more. Overall, these handling methods can be evaluated as to what effect they have on the grain. Damaged grain can often be characterized by the extent to which it reduces storage time. For example, cracked or broken kernels are more susceptible to insect or bacteria as well as chemical degradation. The damage to the actual grain is only one example of losses incurred after harvest. In order to quantify grain damage, one must also understand grain quality. Grain quality is a very broad term and can relate to many topics such as foreign material, chemical compositions, mechanical damage, insect infestations, and many more. These references to quality are highly dependent on the end use of the grain. Certain types of damage may be acceptable to specific industries, whereas others cannot use grain with these issues.

A chicken harvester is a machine used in poultry farming to gather chickens for slaughter.

The S-4 «Stalinets», is a self-propelled combine harvester, made by several different combine harvester plants in the former Soviet Union, from 1947 until 1955. In 1955, the modernised variant, called the S-4M, was introduced; it was put out of production in 1958. In total, 29,582 units were built. In former East Germany, the S-4 combine was built under licence by the IFA as the Fortschritt E 170 series, from 1954 until 1967. Unlike the original S-4, which is powered by an otto engine, the Fortschritt E 170 series combines were all powered by a diesel engine, and some of them came with a chaff waggon rather than a straw waggon.

The Fortschritt E 512 is a self-propelled combine harvester that was made by the East-German manufacturer VEB Mähdrescherwerk Bischofswerda/Singwitz, and sold under the Fortschritt brand. It is the first Fortschritt combine harvester that has been solely developed in the GDR. The E 512 succeeded the Fortschritt E 170 series. At the time of its introduction in the late 1960s, the E 512 was a modern, sought-after combine harvester that could compete well with high-performance combines made in Western countries, such as the Clayson 140 and the Claas Senator. In total, 51,412 units were made from 1968 until 1988, which makes the E 512 the East German combine harvester with the highest production figure.

The Fortschritt E 514 is a self-propelled combine harvester, that was made by the East-German manufacturer VEB Mähdrescherwerk Bischofswerda/Singwitz in Singwitz, and sold under the Fortschritt brand. It is the successor to the Fortschritt E 512, which it did not manage to replace – the E 514 was produced alongside the E 512 from 1982 until 1988.

The Fortschritt E 162, also known as the LBH 52 Kombinus, is a tractor-drawn combine harvester, made by the East-German manufacturer VEB Mähdrescherwerk Boschofswerda/Singwitz in Singwitz, from 1952 until 1956. In total, 54 were built. The E 162 proved to be an unreliable combine, and it was soon replaced by the Fortschritt E 170 series.