A column or pillar in architecture and structural engineering is a structural element that transmits, through compression, the weight of the structure above to other structural elements below. In other words, a column is a compression member. The term column applies especially to a large round support with a capital and a base or pedestal, which is made of stone, or appearing to be so. A small wooden or metal support is typically called a post. Supports with a rectangular or other non-round section are usually called piers.

Rebar, known when massed as reinforcing steel or steel reinforcement, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

The crankset or chainset is the component of a bicycle drivetrain that converts the reciprocating motion of the rider's legs into rotational motion used to drive the chain or belt, which in turn drives the rear wheel. It consists of one or more sprockets, also called chainrings or chainwheels attached to the cranks, arms, or crankarms to which the pedals attach. It is connected to the rider by the pedals, to the bicycle frame by the bottom bracket, and to the rear sprocket, cassette or freewheel via the chain.

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite the head is called the tail. On installation, the deformed end is called the shop head or buck-tail.

Rail transport terms are a form of technical terminology applied to railways. Although many terms are uniform across different nations and companies, they are by no means universal, with differences often originating from parallel development of rail transport systems in different parts of the world, and in the national origins of the engineers and managers who built the inaugural rail infrastructure. An example is the term railroad, used in North America, and railway, generally used in English-speaking countries outside North America and by the International Union of Railways. In English-speaking countries outside the United Kingdom, a mixture of US and UK terms may exist.

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with recent experiences with large earthquakes near urban centers, the need of seismic retrofitting is well acknowledged. Prior to the introduction of modern seismic codes in the late 1960s for developed countries and late 1970s for many other parts of the world, many structures were designed without adequate detailing and reinforcement for seismic protection. In view of the imminent problem, various research work has been carried out. State-of-the-art technical guidelines for seismic assessment, retrofit and rehabilitation have been published around the world – such as the ASCE-SEI 41 and the New Zealand Society for Earthquake Engineering (NZSEE)'s guidelines. These codes must be regularly updated; the 1994 Northridge earthquake brought to light the brittleness of welded steel frames, for example.

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials.

Clinker-built is a method of boat building in which the edges of hull planks overlap each other. Where necessary in larger craft, shorter planks can be joined end to end, creating a longer strake or hull plank.

A swivel is a connection that allows the connected object, such as a gun, chair, swivel caster, or an anchor rode to rotate horizontally or vertically.

A hydraulic cylinder is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment, manufacturing machinery, elevators, and civil engineering. A hydraulic cylinder is a hydraulic actuator that provides linear motion when hydraulic energy is converted into mechanical movement. It can be likened to a muscle in that, when the hydraulic system of a machine is activated, the cylinder is responsible for providing the motion.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

An eye bolt is a bolt with a loop at one end. They are used to firmly attach a securing eye to a structure, so that ropes or cables may then be tied to it.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

Anchor bolts are used to connect structural and non-structural elements to concrete. The connection can be made by a variety of different components: anchor bolts, steel plates, or stiffeners. Anchor bolts transfer different types of load: tension forces and shear forces.

A Howe truss is a truss bridge consisting of chords, verticals, and diagonals whose vertical members are in tension and whose diagonal members are in compression. The Howe truss was invented by William Howe in 1840, and was widely used as a bridge in the mid to late 1800s.

An ironworker is a tradesman who works in the iron-working industry. Ironworkers assemble the structural framework in accordance with engineered drawings and install the metal support pieces for new buildings. They also repair and renovate old structures using reinforced concrete and steel. Ironworkers may work on factories, steel mills, and utility plants.

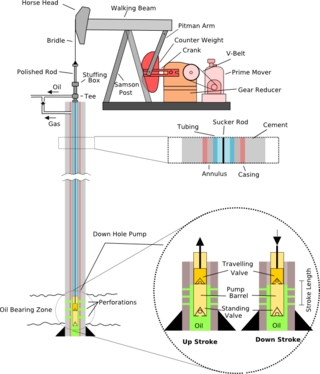

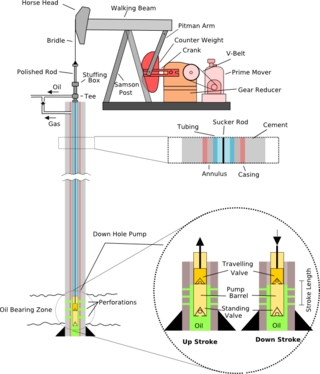

A sucker rod is a steel rod, typically between 25 and 30 feet in length, and threaded at both ends, used in the oil industry to join together the surface and downhole components of a reciprocating piston pump installed in an oil well. The pumpjack is the visible above-ground drive for the well pump, and is connected to the downhole pump at the bottom of the well by a series of interconnected sucker rods. Sucker rods are also commonly available made of fiberglass in 37 1/2 foot lengths and diameters of 3/4, 7/8, 1, and 1 1/4 inch. These are terminated in metallic threaded ends, female at one end and male at the other.

A pipe support or pipe hanger is a designed element that transfer the load from a pipe to the supporting structures. The load includes the weight of the pipe proper, the content that the pipe carries, all the pipe fittings attached to pipe, and the pipe covering such as insulation. The four main functions of a pipe support are to anchor, guide, absorb shock, and support a specified load. Pipe supports used in high or low temperature applications may contain insulation materials. The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions.

A bolt is an externally helical threaded fastener that fastens objects with unthreaded holes together. This is done by applying a twisting force (torque) to a matching nut. The bolt has an external male thread requiring a matching nut with a pre-formed female thread. Unlike a screw, which holds objects together by the restricting motion parallel to the axis of the screw via the normal and frictional forces between the screw's external threads and the internal threads in the objects to be fastened, a bolt prevents that linear motion via the frictional and normal forces between the bolt's external threads and the internal threads of the matching nut, which can be tightened by applying a torque which moves the nut linearly along the axis of the bolt and compresses the objects to be fastened.