Related Research Articles

In physics, cryogenics is the production and behaviour of materials at very low temperatures.

Refrigeration is any of various types of cooling of a space, substance, or system to lower and/or maintain its temperature below the ambient one. Refrigeration is an artificial, or human-made, cooling method.

The following is a timeline of low-temperature technology and cryogenic technology. It also lists important milestones in thermometry, thermodynamics, statistical physics and calorimetry, that were crucial in development of low temperature systems.

Magnetic refrigeration is a cooling technology based on the magnetocaloric effect. This technique can be used to attain extremely low temperatures, as well as the ranges used in common refrigerators.

Liquid air is air that has been cooled to very low temperatures, so that it has condensed into a pale blue mobile liquid. It is stored in specialized containers, such as vacuum flasks, to insulate it from room temperature. Liquid air can absorb heat rapidly and revert to its gaseous state. It is often used for condensing other substances into liquid and/or solidifying them, and as an industrial source of nitrogen, oxygen, argon, and other inert gases through a process called air separation.

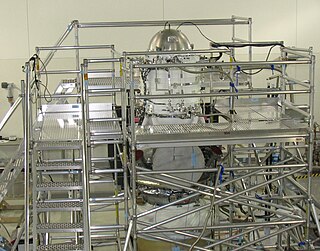

A cryostat is a device used to maintain low cryogenic temperatures of samples or devices mounted within the cryostat. Low temperatures may be maintained within a cryostat by using various refrigeration methods, most commonly using cryogenic fluid bath such as liquid helium. Hence it is usually assembled into a vessel, similar in construction to a vacuum flask or Dewar. Cryostats have numerous applications within science, engineering, and medicine.

Carl Paul Gottfried von Linde was a German scientist, engineer, and businessman. He discovered a refrigeration cycle and invented the first industrial-scale air separation and gas liquefaction processes, which led to the first reliable and efficient compressed-ammonia refrigerator in 1876.

A refrigerated container or reefer is an intermodal container used in intermodal freight transport that is capable of refrigeration for the transportation of temperature-sensitive, perishable cargo such as fruits, vegetables, meat, fish, seafood, and other similar items.

A transcritical cycle is a closed thermodynamic cycle where the working fluid goes through both subcritical and supercritical states. In particular, for power cycles the working fluid is kept in the liquid region during the compression phase and in vapour and/or supercritical conditions during the expansion phase. The ultrasupercritical steam Rankine cycle represents a widespread transcritical cycle in the electricity generation field from fossil fuels, where water is used as working fluid. Other typical applications of transcritical cycles to the purpose of power generation are represented by organic Rankine cycles, which are especially suitable to exploit low temperature heat sources, such as geothermal energy, heat recovery applications or waste to energy plants. With respect to subcritical cycles, the transcritical cycle exploits by definition higher pressure ratios, a feature that ultimately yields higher efficiencies for the majority of the working fluids. Considering then also supercritical cycles as a valid alternative to the transcritical ones, the latter cycles are capable of achieving higher specific works due to the limited relative importance of the work of compression work. This evidences the extreme potential of transcritical cycles to the purpose of producing the most power with the least expenditure.

Thermodynamic heat pump cycles or refrigeration cycles are the conceptual and mathematical models for heat pump, air conditioning and refrigeration systems. A heat pump is a mechanical system that transmits heat from one location at a certain temperature to another location at a higher temperature. Thus a heat pump may be thought of as a "heater" if the objective is to warm the heat sink, or a "refrigerator" or “cooler” if the objective is to cool the heat source. The operating principles in both cases are the same; energy is used to move heat from a colder place to a warmer place.

The pulse tube refrigerator (PTR) or pulse tube cryocooler is a developing technology that emerged largely in the early 1980s with a series of other innovations in the broader field of thermoacoustics. In contrast with other cryocoolers, this cryocooler can be made without moving parts in the low temperature part of the device, making the cooler suitable for a wide variety of applications.

The Kleemenko cycle or one-flow cascade cycle is a single-stream mixed-refrigerant technique used to cool or liquefy gases. The term "Kleemenko cycle" is used in refrigeration if multi-component refrigerants (MCR) are used in a cycle.

A liquid nitrogen engine is powered by liquid nitrogen, which is stored in a tank. Traditional nitrogen engine designs work by heating the liquid nitrogen in a heat exchanger, extracting heat from the ambient air and using the resulting pressurized gas to operate a piston or rotary motor. Vehicles propelled by liquid nitrogen have been demonstrated, but are not used commercially. One such vehicle, Liquid Air, was demonstrated in 1902.

An air separation plant separates atmospheric air into its primary components, typically nitrogen and oxygen, and sometimes also argon and other rare inert gases.

A cryogenic gas plant is an industrial facility that creates molecular oxygen, molecular nitrogen, argon, krypton, helium, and xenon at relatively high purity. As air is made up of nitrogen, the most common gas in the atmosphere, at 78%, with oxygen at 19%, and argon at 1%, with trace gasses making up the rest, cryogenic gas plants separate air inside a distillation column at cryogenic temperatures to produce high purity gasses such as argon, nitrogen, oxygen, and many more with 1 ppm or less impurities. The process is based on the general theory of the Hampson-Linde cycle of air separation, which was invented by Carl von Linde in 1895.

TheVuilleumier cycle was patented by a Swiss-American engineer named Rudolph Vuilleumier in 1918. The purpose of Vuilleumier's machine was to create a heat pump that would use heat at high temperature as energy input. The Vuilleumier cycle...

utilize[s] working gas expansion and compression at three variable volume spaces in order to pump heat from a low to a moderate temperature level. The interesting characteristic of the Vuilleumier machine is that the induced volume variations are realized without the use of work, but thermally. This is the reason why it has a potential to operate at modern applications where the pollution of the environment is not a choice. It is a perfect candidate for such applications, as it consists only of metallic parts and inert gas. Using these units for heating and cooling buildings, large energy savings can be accomplished as they can be operated at small scale in common buildings or at large scale providing heat power to entire building blocks without using fossil fuels. The use of Vuilleumier machines for industrial applications or inside vehicles is also a feasible option. Another field where these machines have already been involved is cryogenics, as they are also able to provide refrigeration at very low temperatures like the very similar and well-known Stirling refrigerators.

The International Institute of Refrigeration (IIR), is an independent intergovernmental science and technology-based organization which promotes knowledge of refrigeration and associated technologies and applications on a global scale that improve quality of life in a cost-effective and environmentally sustainable manner, including:

Cryogenic seals provide a mechanical containment mechanism for materials held at cryogenic temperatures, such as cryogenic fluids. Various techniques, including soldering and welding are available for creating seals; however, specialized materials and processes are necessary to hermetically entrap cryogenic constituents under vacuum-tight conditions. Most commonly used are liquid helium and liquid nitrogen, which boil at very low temperatures, below −153 °C, as well as hydrocarbons with low freezing points and refrigerating mixtures. Pure indium wire or solder preform washers are accepted as the most reliable low temperature sealing materials. When correctly formed, indium will afford leak rates of less than 4.0x10 -9 mbar- liter/sec. Alternative cryogenic seal materials include silicone grease conical seals, and Pb/Sn (lead-tin) wire seals.

The Kamerlingh Onnes Award is in recognition of special merits of scientists active in the field of refrigeration technology, cryogenics and more generally low-temperature science and technology. It was founded in 1948 by the Royal Dutch Association of Refrigeration The name of the award is intended to keep the memory of Heike Kamerlingh Onnes alive. The award is assigned typically every four years and the winners get a golden medal and a certificate.

A cascade refrigeration cycle is a multi-stage thermodynamic cycle. An example two-stage process is shown at right. The cascade cycle is often employed for devices such as ULT freezers.

References

- ↑ "Cryogenics | Low-Temperature Physics & Applications | Britannica". www.britannica.com. Retrieved 2024-05-02.

- ↑ Kanojiya, Harsh (April 2017). "Design and Thermal Analysis of Rectification Column for Separation of Nitrogen and Oxygen using Rectification Column Method" (PDF).

- ↑ "Cryogenics". ITER. Retrieved 2024-05-02.