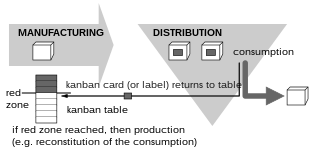

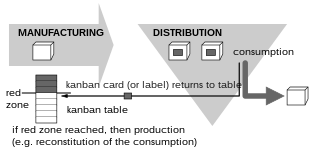

Kanban is a scheduling system for lean manufacturing. Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the Toyota nameplate system in the automotive industry.

In software development, agile practices include requirements discovery and solutions improvement through the collaborative effort of self-organizing and cross-functional teams with their customer(s)/end user(s), Popularized in the 2001 Manifesto for Agile Software Development, these values and principles were derived from and underpin a broad range of software development frameworks, including Scrum and Kanban.

In agile principles, timeboxing allocates a maximum unit of time to an activity, called a timebox, within which a planned activity takes place. It is used by agile principles-based project management approaches and for personal time management.

Lean software development is a translation of lean manufacturing principles and practices to the software development domain. Adapted from the Toyota Production System, it is emerging with the support of a pro-lean subculture within the agile community. Lean offers a solid conceptual framework, values and principles, as well as good practices, derived from experience, that support agile organizations.

Operations management is an area of management concerned with designing and controlling the process of production and redesigning business operations in the production of goods or services. It involves the responsibility of ensuring that business operations are efficient in terms of using as few resources as needed and effective in meeting customer requirements.

Shortest job next (SJN), also known as shortest job first (SJF) or shortest process next (SPN), is a scheduling policy that selects for execution the waiting process with the smallest execution time. SJN is a non-preemptive algorithm. Shortest remaining time is a preemptive variant of SJN.

Scrum is an agile project management system commonly used in software development and other industries.

Value-stream mapping, also known as material- and information-flow mapping, is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. A value stream map is a visual tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process.

A stand-up meeting (stum) is a meeting in which attendees typically participate while standing. The discomfort of standing for long periods is intended to keep the meetings short.

A burndown chart or burn down chart is a graphical representation of work left to do versus time. The outstanding work is often on the vertical axis, with time along the horizontal. A burn down chart is a run chart of remaining work. It is useful for predicting when all of the work will be completed. It is often used in agile software development methodologies such as Scrum. However, burn down charts can be applied to any project containing measurable progress over time.

In software engineering, a software development process is a process of planning and managing software development. It typically involves dividing software development work into smaller, parallel, or sequential steps or sub-processes to improve design and/or product management. It is also known as a software development life cycle (SDLC). The methodology may include the pre-definition of specific deliverables and artifacts that are created and completed by a project team to develop or maintain an application.

Lean project management is the application of lean concepts such as lean construction, lean manufacturing and lean thinking to project management.

Kanban is a lean method to manage and improve work across human systems. This approach aims to manage work by balancing demands with available capacity, and by improving the handling of system-level bottlenecks.

The following outline is provided as an overview of and topical guide to project management:

A kanban board is one of the tools that can be used to implement kanban to manage work at a personal or organizational level.

Lean CFP Driven is a new approach which takes into account not only the widely implemented Lean manufacturing, but combines the principles of Lean with the Operating Curve, an approach based on the theoretical approach of queuing theory developed in academia in the 1970s. The goal of Lean CFP Driven is to eliminate waste in order to achieve higher quality, increase productivity and at the same time understand the relationship between utilization, lead time and variability in order to maximize performance within the semiconductor industry.

Disciplined agile delivery (DAD) is the software development portion of the Disciplined Agile Toolkit. DAD enables teams to make simplified process decisions around incremental and iterative solution delivery. DAD builds on the many practices espoused by advocates of agile software development, including scrum, agile modeling, lean software development, and others.

eXtreme Manufacturing (XM) is an iterative and incremental framework for manufacturing improvement and new product development that was inspired by the software development methodology Scrum and the systematic waste-elimination (lean) production scheduling system Kanban(かんばん ).

Scrumban is an Agile aligned approach to product delivery which is a hybrid of Scrum and Kanban. Scrumban was originally designed as a way to transition from Scrum to Kanban.

The scaled agile framework (SAFe) is a set of organization and workflow patterns intended to guide enterprises in scaling lean and agile practices. Along with disciplined agile delivery (DAD), SAFe is one of a growing number of frameworks that seek to address the problems encountered when scaling beyond a single team.