Related Research Articles

In chemistry, a monomer is a molecule that can react together with other monomer molecules to form a larger polymer chain or three-dimensional network in a process called polymerization.

A polymer (;) is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals.

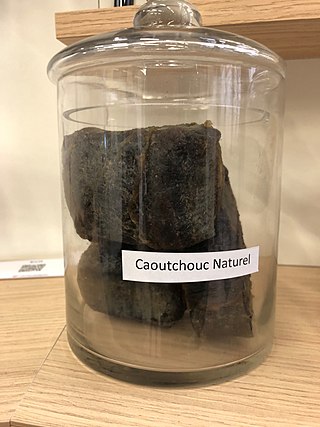

Rubber, also called India rubber, latex, Amazonian rubber, caucho, or caoutchouc, as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Thailand, Malaysia, Indonesia, and Cambodia are four of the leading rubber producers.

In polymer chemistry, a copolymer is a polymer derived from more than one species of monomer. The polymerization of monomers into copolymers is called copolymerization. Copolymers obtained from the copolymerization of two monomer species are sometimes called bipolymers. Those obtained from three and four monomers are called terpolymers and quaterpolymers, respectively. Copolymers can be characterized by a variety of techniques such as NMR spectroscopy and size-exclusion chromatography to determine the molecular size, weight, properties, and composition of the material.

A synthetic rubber is an artificial elastomer. They are polymers synthesized from petroleum byproducts. About 32 million metric tons of rubbers are produced annually in the United States, and of that amount two thirds are synthetic. Synthetic rubber, just like natural rubber, has many uses in the automotive industry for tires, door and window profiles, seals such as O-rings and gaskets, hoses, belts, matting, and flooring. They offer a different range of physical and chemical properties which can improve the reliability of a given product or application. Synthetic rubbers are superior to natural rubbers in two major respects: thermal stability, and resistance to oils and related compounds. They are more resistant to oxidizing agents, such as oxygen and ozone which can reduce the life of products like tires.

In polymer chemistry, anionic addition polymerization is a form of chain-growth polymerization or addition polymerization that involves the polymerization of monomers initiated with anions. The type of reaction has many manifestations, but traditionally vinyl monomers are used. Often anionic polymerization involves living polymerizations, which allows control of structure and composition.

The Tire Society is a non-profit professional body, specifically an engineering society, whose mission is to increase and disseminate knowledge as it pertains to the science and technology of tires. It hosts a two-day meeting and conference every year. In addition, it publishes a peer reviewed technical journal, Tire Science and Technology.

Solution polymerization is a method of industrial polymerization. In this procedure, a monomer is dissolved in a non-reactive solvent that contains a catalyst or initiator.

Ivan Ivanovich Ostromislensky was a Russian organic chemist. He is credited as the pioneer in studying polymerization of synthetic rubber as well as inventor of various industrial technologies for production of synthetic rubber, polymers and pharmaceuticals.

The Charles Goodyear Medal is the highest honor conferred by the American Chemical Society, Rubber Division. Established in 1941, the award is named after Charles Goodyear, the discoverer of vulcanization, and consists of a gold medal, a framed certificate and prize money. The medal honors individuals for "outstanding invention, innovation, or development which has resulted in a significant change or contribution to the nature of the rubber industry". Awardees give a lecture at an ACS Rubber Division meeting, and publish a review of their work in the society's scientific journal Rubber Chemistry and Technology.

The Melvin Mooney Distinguished Technology Award is a professional award conferred by the American Chemical Society, Rubber Division. Established in 1983, the award is named after Melvin Mooney, developer of the Mooney viscometer and of the Mooney-Rivlin hyperelastic law. The award consists of an engraved plaque and prize money. The medal honors individuals "who have exhibited exceptional technical competency by making significant and repeated contributions to rubber science and technology".

David Spence was one of the pioneering rubber chemists. He helped the war effort during the Second World War by devising new ways of extracting natural rubbers from plants, and worked to improve the processing of the rubber. Over the course of his career, he worked to improve the dyeing processes for rubber products and the vulcanization of rubber, and in developing new accelerants for strengthening lower-quality natural rubber. In 1941, he became the first recipient of the Charles Goodyear Medal, awarded by the American Chemical Society.

Samuel Emmett Horne Jr. was a research scientist at B. F. Goodrich noted for first synthesizing cis-1,4-polyisoprene, the main polymer contained in natural tree rubber, using Ziegler catalysis. Earlier attempts to produce synthetic rubber from isoprene had been unsuccessful, but in 1955, Horne prepared 98 percent cis-1,4-polyisoprene via the stereospecific polymerization of isoprene. The product of this reaction differs from natural rubber only slightly. It contains a small amount of cis-1,2-polyisoprene, but it is indistinguishable from natural rubber in its physical properties.

Adel F. Halasa is an American scientist noted for his contributions to the development of rubber, particularly in the area of tire tread polymers for the Goodyear AquaTred tire. In 1997, he won the Charles Goodyear Medal, bestowed by the American Chemical Society, Rubber Division to individuals who "have been the principal inventor(s), innovator(s), or developer(s) of a significant change or contribution to the rubber industry".

The purpose of the Sparks–Thomas Award, given by the American Chemical Society, Rubber Division, is to recognize and encourage outstanding contributions and innovations in the field of elastomers by younger scientists, technologists, and engineers. The award is named for Exxon scientists William J. Sparks and Robert M. Thomas, co-inventors of Butyl rubber.

Christopher Ward Macosko (1944) is an American chemical engineer and professor emeritus in the department of chemical engineering and materials science at the University of Minnesota. He is internationally known for his work in polymer science and engineering, especially in the areas of rheology and polymer processing. Macosko is an author of more than 500 academic papers, dozens of patents, and two books including the text: "Rheology: Principles, Measurements and Applications". He served as director of the Industrial Partnership for Research in Interfacial and Materials Engineering (IPRIME), a university-industry consortium at the University of Minnesota, from 1999 to 2018. Macosko and his wife Kathleen have been married since 1967 and are long-time residents of Minneapolis. They have four children and 12 grandchildren.

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of varying hardness, elasticity, and mechanical durability by heating them with sulfur or sulfur-containing compounds. Sulfur forms cross-linking bridges between sections of polymer chains which affects the mechanical and electronic properties. Many products are made with vulcanized rubber, including tires, shoe soles, hoses, and conveyor belts. The term vulcanization is derived from Vulcan, the Roman god of fire.

Roderic Quirk is an Emeritus University of Akron professor noted for contributions to anionic polymerization technology that is used to produce butadiene, isoprene and styrene homo and block copolymers.

Prof. Yasuyuki Tanaka was a Tokyo University of Agriculture and Technology professor noted for elucidating the molecular structure of natural rubber, and for his work in synthetic rubber.

Walter H. Waddell is a retired ExxonMobil Chemical senior research associate and consultant to the tire and rubber industry with expertise in silica technology, rubber compounding, butyl polymer applications and tire aging. Since 2015 he has served on the technical committee of the International Tire Exhibition & Conference (ITEC) for Tire Manufacturing.

References

- ↑ McIntyre, James E. III (7 June 2021). "40 Years and More of Tire Science and Technology: A History of The Tire Society". Tire Science and Technology. 50 (2): 100–187. doi:10.2346/tire.21.20015. S2CID 240119323 . Retrieved 8 August 2022.

- ↑ Shaw, David (24 June 2010). "Work progressing toward making green isoprene monomer". Rubber and Plastics News. Crain. Retrieved 28 September 2023.

- ↑ Bomgardner, Melody (25 July 2016). "Dandelions, the scourge of lawns, may be a fount of rubber". Chem. Eng. News. American Chemical Society. Retrieved 28 September 2023.

- ↑ Schunk, Andrew (8 September 2021). "Tire Society stays true to mission, industry". Tire Business. Crain. Retrieved 28 September 2023.

- ↑ "Journal of Applied Polymer Science". wiley.com. Wiley. 140 (32). 20 August 2023. doi: 10.1002/app.52584 . Retrieved 28 September 2023.

- ↑ Whited, Gregory M.; Feher, Frank J.; Benko, David A.; Cervin, Marguerite A.; Chotani, Gopal K.; McAuliffe, Joseph C.; LaDuca, Richard J.; Ben-Shoshan, Eliahu A.; Sanford., Karl J. (2010). "TECHNOLOGY UPDATE: Development of a gas-phase bioprocess for isoprene-monomer production using metabolic pathway engineering". Industrial Biotechnology. 6 (3): 152–163. doi:10.1089/ind.2010.6.152 . Retrieved 28 September 2023.