Forecasting is the process of making predictions of the future based on past and present data and most commonly by analysis of trends. A commonplace example might be estimation of some variable of interest at some specified future date. Prediction is a similar, but more general term. Both might refer to formal statistical methods employing time series, cross-sectional or longitudinal data, or alternatively to less formal judgmental methods. Usage can differ between areas of application: for example, in hydrology the terms "forecast" and "forecasting" are sometimes reserved for estimates of values at certain specific future times, while the term "prediction" is used for more general estimates, such as the number of times floods will occur over a long period.

Service management in the manufacturing context, is integrated into supply chain management as the intersection between the actual sales and the customer point of view. The aim of high performance service management is to optimize the service-intensive supply chains, which are usually more complex than the typical finished-goods supply chain. Most service-intensive supply chains require larger inventories and tighter integration with field service and third parties. They also must accommodate inconsistent and uncertain demand by establishing more advanced information and product flows. Moreover, all processes must be coordinated across numerous service locations with large numbers of parts and multiple levels in the supply chain.

Demand management is a planning methodology used to forecast, plan for and manage the demand for products and services. This can be at macro-levels as in economics and at micro-levels within individual organizations. For example, at macro-levels, a government may influence interest rates in order to regulate financial demand. At the micro-level, a cellular service provider may provide free night and weekend use in order to reduce demand during peak hours.

The business terms push and pull originated in logistics and supply chain management, but are also widely used in marketing, and is also a term widely used in the hotel distribution business. Walmart is an example of a company that uses the push vs. pull strategy.

The demand chain is that part of the value chain which drives demand.

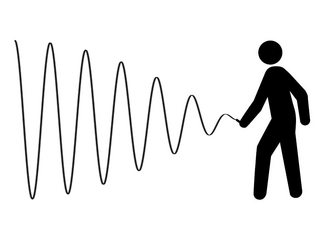

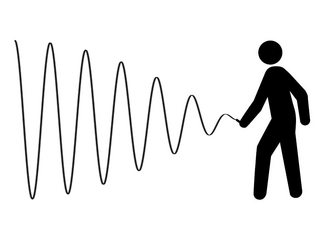

The bullwhip effect is a distribution channel phenomenon in which forecasts yield supply chain inefficiencies. It refers to increasing swings in inventory in response to shifts in customer demand as one moves further up the supply chain. The concept first appeared in Jay Forrester's Industrial Dynamics (1961) and thus it is also known as the Forester effect. The bullwhip effect was named for the way the amplitude of a whip increases down its length. The further from the originating signal, the greater the distortion of the wave pattern. In a similar manner, forecast accuracy decreases as one moves upstream along the supply chain. For example, many consumer goods have fairly consistent consumption at retail but this signal becomes more chaotic and unpredictable as the focus moves away from consumer purchasing behavior.

Demand-chain management (DCM) is the management of relationships between suppliers and customers to deliver the best value to the customer at the least cost to the demand chain as a whole. Demand-chain management is similar to supply-chain management but with special regard to the customers.

Supply-chain optimization is the application of processes and tools to ensure the optimal operation of a manufacturing and distribution supply chain. This includes the optimal placement of inventory within the supply chain, minimizing operating costs including manufacturing costs, transportation costs, and distribution costs. The process often involves the application of mathematical modelling techniques using computer software.

Collaborative Planning, Forecasting and Replenishment (CPFR), a trademark of GS1 US, is a concept that aims to enhance supply chain integration by supporting and assisting joint practices. CPFR seeks cooperative management of inventory through joint visibility and replenishment of products throughout the supply chain. Information shared between suppliers and retailers aids in planning and satisfying customer demands through a supportive system of shared information. This allows for continuous updating of inventory and upcoming requirements, making the end-to-end supply chain process more efficient. Efficiency is created through the decrease expenditures for merchandising, inventory, logistics, and transportation across all trading partners.

Revenue management is the application of disciplined analytics that predict consumer behaviour at the micro-market levels and optimize product availability and price to maximize revenue growth. The primary aim of revenue management is selling the right product to the right customer at the right time for the right price and with the right pack. The essence of this discipline is in understanding customers' perception of product value and accurately aligning product prices, placement and availability with each customer segment.

Supply-chain operations reference (SCOR) model is a process reference model developed and endorsed by the Supply Chain Council as the cross-industry, standard diagnostic tool for supply chain management. The SCOR model describes the business activities associated with satisfying a customer's demand, which include plan, source, make, deliver, return and enable. Use of the model includes analyzing the current state of a company's processes and goals, quantifying operational performance, and comparing company performance to benchmark data. SCOR has developed a set of metrics for supply chain performance, and Supply Chain Council members have formed industry groups to collect best practices information that companies can use to elevate their supply chain models.

Supply-chain-management software (SCMS) is the software tools or modules used in executing supply chain transactions, managing supplier relationships and controlling associated business processes.

Sales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment and synchronization among all functions of the organization. The S&OP process includes an updated forecast that leads to a sales plan, production plan, inventory plan, customer lead time (backlog) plan, new product development plan, strategic initiative plan and resulting financial plan. Plan frequency and planning horizon depend on the specifics of the industry. Short product life cycles and high demand volatility require a tighter S&OP than steadily consumed products. Done well, the S&OP process also enables effective supply chain management.

Customer Demand Planning (CDP) is a business-planning process that enables sales teams to develop demand forecasts as input to service-planning processes, production, inventory planning and revenue planning.

Demand forecasting is a field of predictive analytics which tries to understand and predict customer demand to optimize supply decisions by corporate supply chain and business management. Demand forecasting involves quantitative methods such as the use of data, and especially historical sales data, as well as statistical techniques from test markets. Demand forecasting may be used in production planning, inventory management, and at times in assessing future capacity requirements, or in making decisions on whether to enter a new market.

Trade Promotion Management (TPM) typically refers to one or more software applications that assist companies in managing their complex trade promotion activity. Trade Promotion Management is a challenge faced by most CPG/FMCG companies around the globe. Consumer goods companies spend substantial amounts of time and money—14 percent of revenue, according to an AMR Research study—on promotions with retailers designed to boost revenue or increase/protect market share.

Demand sensing is a forecasting method that leverages new mathematical techniques and near real-time information to create an accurate forecast of demand, based on the current realities of the supply chain. Gartner, Inc. insight on demand sensing can be found in its report, "Supply Chain Strategy for Manufacturing Leaders: The Handbook for Becoming Demand Driven."

Inventory optimization is a method of balancing capital investment constraints or objectives and service-level goals over a large assortment of stock-keeping units (SKUs) while taking demand and supply volatility into account.

Trade Promotion Forecasting (TPF) is the process that attempts to discover multiple correlations between trade promotion characteristics and historic demand in order to provide accurate demand forecasting for future campaigns. The ability to distinguish the uplift or demand due to the impact of the trade promotion as opposed to baseline demand is fundamental to model promotion behavior. Model determination enables what-if analysis to evaluate different campaign scenarios with the goal of improving promotion effectiveness and ROI at the product-channel level by selecting the best scenario.

Retail back-office software is used to manage business operations that are not related to direct sales efforts and interfaces that are not seen by consumers. Typically, the business processes managed with back-office software include some combination of inventory control, price book management, manufacturing, and supply chain management (SCM). Back-office software is distinct from front-office software, which typically refers to customer relationship management (CRM) software used for managing sales, marketing, and other customer-centric activities.