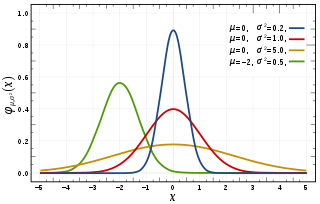

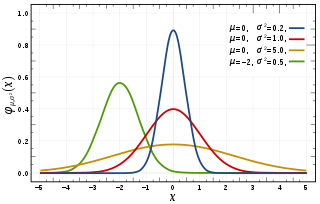

In probability theory and statistics, a normal distribution or Gaussian distribution is a type of continuous probability distribution for a real-valued random variable. The general form of its probability density function is

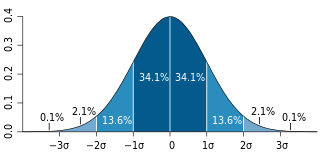

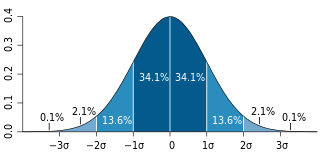

In statistics, the standard deviation is a measure of the amount of variation of the values of a variable about its mean. A low standard deviation indicates that the values tend to be close to the mean of the set, while a high standard deviation indicates that the values are spread out over a wider range. The standard deviation is commonly used in the determination of what constitutes an outlier and what does not. Standard deviation may be abbreviated SD or std dev, and is most commonly represented in mathematical texts and equations by the lowercase Greek letter σ (sigma), for the population standard deviation, or the Latin letter s, for the sample standard deviation.

Material requirements planning (MRP) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but it is possible to conduct MRP by hand as well.

In mathematics, the Radon transform is the integral transform which takes a function f defined on the plane to a function Rf defined on the (two-dimensional) space of lines in the plane, whose value at a particular line is equal to the line integral of the function over that line. The transform was introduced in 1917 by Johann Radon, who also provided a formula for the inverse transform. Radon further included formulas for the transform in three dimensions, in which the integral is taken over planes. It was later generalized to higher-dimensional Euclidean spaces and more broadly in the context of integral geometry. The complex analogue of the Radon transform is known as the Penrose transform. The Radon transform is widely applicable to tomography, the creation of an image from the projection data associated with cross-sectional scans of an object.

In statistical inference, specifically predictive inference, a prediction interval is an estimate of an interval in which a future observation will fall, with a certain probability, given what has already been observed. Prediction intervals are often used in regression analysis.

In econometrics, the autoregressive conditional heteroskedasticity (ARCH) model is a statistical model for time series data that describes the variance of the current error term or innovation as a function of the actual sizes of the previous time periods' error terms; often the variance is related to the squares of the previous innovations. The ARCH model is appropriate when the error variance in a time series follows an autoregressive (AR) model; if an autoregressive moving average (ARMA) model is assumed for the error variance, the model is a generalized autoregressive conditional heteroskedasticity (GARCH) model.

Service level measures the performance of a system, service or supply. Certain goals are defined and the service level gives the percentage to which those goals should be achieved.

The newsvendormodel is a mathematical model in operations management and applied economics used to determine optimal inventory levels. It is (typically) characterized by fixed prices and uncertain demand for a perishable product. If the inventory level is , each unit of demand above is lost in potential sales. This model is also known as the newsvendor problem or newsboy problem by analogy with the situation faced by a newspaper vendor who must decide how many copies of the day's paper to stock in the face of uncertain demand and knowing that unsold copies will be worthless at the end of the day.

The covariant formulation of classical electromagnetism refers to ways of writing the laws of classical electromagnetism in a form that is manifestly invariant under Lorentz transformations, in the formalism of special relativity using rectilinear inertial coordinate systems. These expressions both make it simple to prove that the laws of classical electromagnetism take the same form in any inertial coordinate system, and also provide a way to translate the fields and forces from one frame to another. However, this is not as general as Maxwell's equations in curved spacetime or non-rectilinear coordinate systems.

In mathematical finance, the SABR model is a stochastic volatility model, which attempts to capture the volatility smile in derivatives markets. The name stands for "stochastic alpha, beta, rho", referring to the parameters of the model. The SABR model is widely used by practitioners in the financial industry, especially in the interest rate derivative markets. It was developed by Patrick S. Hagan, Deep Kumar, Andrew Lesniewski, and Diana Woodward.

Expected shortfall (ES) is a risk measure—a concept used in the field of financial risk measurement to evaluate the market risk or credit risk of a portfolio. The "expected shortfall at q% level" is the expected return on the portfolio in the worst of cases. ES is an alternative to value at risk that is more sensitive to the shape of the tail of the loss distribution.

In probability and statistics, the truncated normal distribution is the probability distribution derived from that of a normally distributed random variable by bounding the random variable from either below or above. The truncated normal distribution has wide applications in statistics and econometrics.

The reorder point (ROP), also reorder level (ROL) or "optimal re-order level", is the level of inventory which triggers an action to replenish that particular inventory. It is a minimum amount of an item which a firm holds in stock, such that, when stock falls to this amount, the item must be reordered. It is normally calculated as the forecast usage during the replenishment lead time plus safety stock. In the EOQ model, it was assumed that there is no time lag between ordering and receipt of materials.

In set theory, a mathematical discipline, the Jensen hierarchy or J-hierarchy is a modification of Gödel's constructible hierarchy, L, that circumvents certain technical difficulties that exist in the constructible hierarchy. The J-Hierarchy figures prominently in fine structure theory, a field pioneered by Ronald Jensen, for whom the Jensen hierarchy is named. Rudimentary functions describe a method for iterating through the Jensen hierarchy.

Demand forecasting, also known as demand planning and sales forecasting (DP&SF), involves the prediction of the quantity of goods and services that will be demanded by consumers or business customers at a future point in time. More specifically, the methods of demand forecasting entail using predictive analytics to estimate customer demand in consideration of key economic conditions. This is an important tool in optimizing business profitability through efficient supply chain management. Demand forecasting methods are divided into two major categories, qualitative and quantitative methods:

EMSR stands for Expected Marginal Seat Revenue and is a very popular heuristic in Revenue Management. There are two versions: EMSRa and EMSRb, both of which were introduced by Peter Belobaba. Both methods are for n-class, static, single-resource problems. Because the models are static some assumptions apply: classes are indexed in such a way that the fare for the highest class, , is higher than the fare for the next highest class, , so > > ... > ; demand arrives in a strict low to high order in stages that are indexed with j as well; demand for class j is distributed with cdf . For simplicity it is also assumed that demand, capacity and the distributions are continuous, although it is not very difficult to drop this assumption.

In mathematical physics, in particular electromagnetism, the Riemann–Silberstein vector or Weber vector named after Bernhard Riemann, Heinrich Martin Weber and Ludwik Silberstein, is a complex vector that combines the electric field E and the magnetic field B.

The base stock model is a statistical model in inventory theory. In this model inventory is refilled one unit at a time and demand is random. If there is only one replenishment, then the problem can be solved with the newsvendor model.

Non-homogeneous Gaussian regression (NGR) is a type of statistical regression analysis used in the atmospheric sciences as a way to convert ensemble forecasts into probabilistic forecasts. Relative to simple linear regression, NGR uses the ensemble spread as an additional predictor, which is used to improve the prediction of uncertainty and allows the predicted uncertainty to vary from case to case. The prediction of uncertainty in NGR is derived from both past forecast errors statistics and the ensemble spread. NGR was originally developed for site-specific medium range temperature forecasting, but has since also been applied to site-specific medium-range wind forecasting and to seasonal forecasts, and has been adapted for precipitation forecasting. The introduction of NGR was the first demonstration that probabilistic forecasts that take account of the varying ensemble spread could achieve better skill scores than forecasts based on standard model output statistics approaches applied to the ensemble mean.

In inventory theory, the (Q,r) model is used to determine optimal ordering policies. Its is a class of inventory control models that generalize and combine elements of both the Economic Order Quantity (EOQ) model and the base stock model. The (Q,r) model addresses the question of when and how much to order, aiming to minimize total inventory costs, which typically include ordering costs, holding costs, and shortage costs. It specifies that an order of size Q should be placed when the inventory level reaches a reorder point r. The (Q,r) model is widely applied in various industries to manage inventory effectively and efficiently.