Kevlar (para-aramid) is a strong, heat-resistant synthetic fiber, related to other aramids such as Nomex and Technora. Developed by Stephanie Kwolek at DuPont in 1965, the high-strength material was first used commercially in the early 1970s as a replacement for steel in racing tires. It is typically spun into ropes or fabric sheets that can be used as such, or as an ingredient in composite material components.

Nylon is a family of synthetic polymers with amide backbones, usually linking aliphatic or semi-aromatic groups.

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene and is a PFAS that has numerous applications. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a spin-off from DuPont, which originally discovered the compound in 1938.

Ultraviolet (UV) is a form of electromagnetic radiation with wavelength shorter than that of visible light, but longer than X-rays. UV radiation is present in sunlight, and constitutes about 10% of the total electromagnetic radiation output from the Sun. It is also produced by electric arcs; Cherenkov radiation; and specialized lights, such as mercury-vapor lamps, tanning lamps, and black lights.

Fiber or fibre is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate fibers, for example carbon fiber and ultra-high-molecular-weight polyethylene.

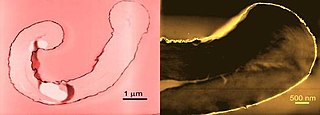

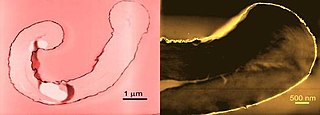

Carbon fibers or carbon fibres are fibers about 5 to 10 micrometers (0.00020–0.00039 in) in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers.

In the study of heat transfer, radiative cooling is the process by which a body loses heat by thermal radiation. As Planck's law describes, every physical body spontaneously and continuously emits electromagnetic radiation.

Ionizing radiation, including nuclear radiation, consists of subatomic particles or electromagnetic waves that have sufficient energy to ionize atoms or molecules by detaching electrons from them. Some particles can travel up to 99% of the speed of light, and the electromagnetic waves are on the high-energy portion of the electromagnetic spectrum.

Radiation protection, also known as radiological protection, is defined by the International Atomic Energy Agency (IAEA) as "The protection of people from harmful effects of exposure to ionizing radiation, and the means for achieving this". Exposure can be from a source of radiation external to the human body or due to internal irradiation caused by the ingestion of radioactive contamination.

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code (RIC) and are identified as "Other", 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A (BPA).

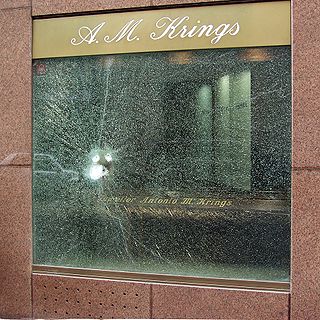

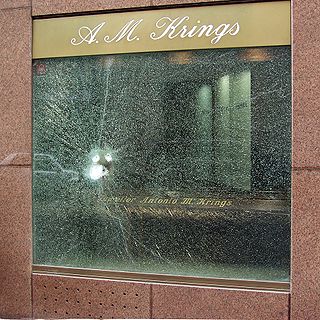

Bulletproof glass, ballistic glass, transparent armor, or bullet-resistant glass is a strong and optically transparent material that is particularly resistant to penetration by projectiles. Like any other material, it is not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so that it can flex instead of shatter. The index of refraction for all of the glasses used in the bulletproof layers must be almost the same to keep the glass transparent and allow a clear, undistorted view through the glass. Bulletproof glass varies in thickness from 3⁄4 to 3+1⁄2 inches.

Poly(allyl diglycol carbonate) (PADC) is a plastic commonly used in the manufacture of eyeglass lenses alongside the material PMMA (polymethyl methacrylate). The monomer is allyl diglycol carbonate (ADC). The term CR-39 technically refers to the ADC monomer, but is more commonly used to refer to the finished plastic.

Radiation chemistry is a subdivision of nuclear chemistry which studies the chemical effects of ionizing radiation on matter. This is quite different from radiochemistry, as no radioactivity needs to be present in the material which is being chemically changed by the radiation. An example is the conversion of water into hydrogen gas and hydrogen peroxide.

Nonwoven fabric or non-woven fabric is a fabric-like material made from staple fibre (short) and long fibres, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam.

Nanofabrics are textiles engineered with small particles that give ordinary materials advantageous properties such as superhydrophobicity, odor and moisture elimination, increased elasticity and strength, and bacterial resistance. Depending on the desired property, a nanofabric is either constructed from nanoscopic fibers called nanofibers, or is formed by applying a solution containing nanoparticles to a regular fabric. Nanofabrics research is an interdisciplinary effort involving bioengineering, molecular chemistry, physics, electrical engineering, computer science, and systems engineering. Applications of nanofabrics have the potential to revolutionize textile manufacturing and areas of medicine such as drug delivery and tissue engineering.

Industrial radiography is a modality of non-destructive testing that uses ionizing radiation to inspect materials and components with the objective of locating and quantifying defects and degradation in material properties that would lead to the failure of engineering structures. It plays an important role in the science and technology needed to ensure product quality and reliability. In Australia, industrial radiographic non-destructive testing is colloquially referred to as "bombing" a component with a "bomb".

Radiation damage is the effect of ionizing radiation on physical objects including non-living structural materials. It can be either detrimental or beneficial for materials.

A conductive textile is a fabric which can conduct electricity. Conductive textiles known as lamé are made with guipé thread or yarn that is conductive because it is composed of metallic fibers wrapped around a non-metallic core or has a metallic coating. A different way of achieving conductivity is to weave metallic strands into the textile.

Carbon fiber-reinforced polymers, carbon-fibre-reinforced polymers, carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic, also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications.

The Bigelow Expandable Activity Module (BEAM) is an experimental expandable space station module developed by Bigelow Aerospace, under contract to NASA, for testing as a temporary module on the International Space Station (ISS) from 2016 to at most 2028, when the contract can not be extended any further. It arrived at the ISS on 10 April 2016, was berthed to the station on 16 April 2016, and was expanded and pressurized on 28 May 2016. Although originally planned to be a two year test, it has exceeded expectations and is used as additional cargo storage. The module is under ownership of NASA after Bigelow Aerospace suspended operations in 2021.