An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well. Wells are created by drilling down into an oil or gas reserve that is then mounted with an extraction device such as a pumpjack which allows extraction from the reserve. Creating the wells can be an expensive process, costing at least hundreds of thousands of dollars, and costing much more when in hard to reach areas, e.g., when creating offshore oil platforms. The process of modern drilling for wells first started in the 19th century, but was made more efficient with advances to oil drilling rigs during the 20th century.

A mud engineer works on an oil well or gas well drilling rig, and is responsible for ensuring the properties of the drilling fluid, also known as drilling mud, are within designed specifications.

Well control is the technique used in oil and gas operations such as drilling, well workover and well completion for maintaining the hydrostatic pressure and formation pressure to prevent the influx of formation fluids into the wellbore. This technique involves the estimation of formation fluid pressures, the strength of the subsurface formations and the use of casing and mud density to offset those pressures in a predictable fashion. Understanding pressure and pressure relationships is important in well control.

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also used for much simpler boreholes, such as water wells. One of the functions of drilling mud is to carry cuttings out of the hole.

Mud logging is the creation of a detailed record of a borehole by examining the cuttings of rock brought to the surface by the circulating drilling medium. Mud logging is usually performed by a third-party mud logging company. This provides well owners and producers with information about the lithology and fluid content of the borehole while drilling. Historically it is the earliest type of well log. Under some circumstances compressed air is employed as a circulating fluid, rather than mud. Although most commonly used in petroleum exploration, mud logging is also sometimes used when drilling water wells and in other mineral exploration, where drilling fluid is the circulating medium used to lift cuttings out of the hole. In hydrocarbon exploration, hydrocarbon surface gas detectors record the level of natural gas brought up in the mud. A mobile laboratory is situated by the mud logging company near the drilling rig or on deck of an offshore drilling rig, or on a drill ship.

A derrickhand or derrickman is the person who sits atop the derrick on a drilling rig. Though the exact duties vary from rig to rig, they almost always report directly to the driller. Their job is to guide the stands of the drill pipe into the fingers at the top of the derrick. Other duties might include monitoring pH and calcium levels, viscosity and the mud weight (density), adding chemicals and oil based fluids, and being responsible for the shale shakers and mud pump.

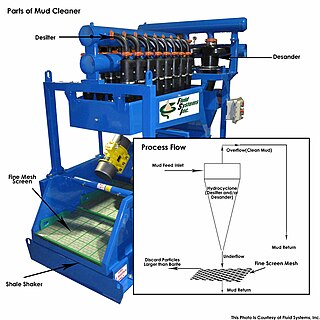

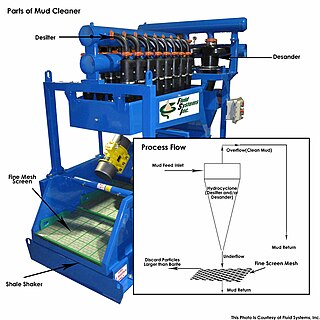

Shale shakers are components of drilling equipment used in many industries, such as coal cleaning, mining, oil and gas drilling.They are the first phase of a solids control system on a drilling rig, and are used to remove large solids (cuttings) from the drilling fluid ("mud").

Annular velocity is the speed of the drilling fluid's movement in a column called an annulus in oil wells. It is commonly measured in feet per minute (ft/min) or meters per minute (m/min). Annular velocity is often abbreviated as AV, though this is not exclusively so, as AV also refers to apparent viscosity which is calculated from rheometer readings from tests that the mud engineer performs.

A mud tank is an open-top container, typically made of square steel tube and steel plate, to store drilling fluid on a drilling rig. They are also called mud pits, as they were once simple pits in the earth.

A mud pump, is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

A flow line, used on a drilling rig, is a large diameter pipe that is connected to the bell nipple and extends to the possum belly and acts as a return line,, to the mud

A Bell nipple is a section of large diameter pipe fitted to the top of the blowout preventers that the flow line attaches to via a side outlet, to allow the drilling fluid to flow back over the shale shakers to the mud tanks.

Effective solids control can be attributed to the overall performance of all the components of the mud systems. Conditioning the drilling fluid with the goal of dramatically lowering maintenance cost, avoiding excessive chemical treatment and maintaining mud systems volume will decrease the chance of equipment failure, unnecessary high mud costs, hole and drilling problems.

Mud Gas Separator is commonly called a gas-buster or poor boy degasser. It captures and separates the large volumes of free gas within the drilling fluid. If there is a "kick" situation, this vessel separates the mud and the gas by allowing it to flow over baffle plates. The gas then is forced to flow through a line, venting to a flare. A "kick" situation happens when the annular hydrostatic pressure in a drilling well temporarily falls below that of the formation, or pore, pressure in a permeable section downhole, and before control of the situation is lost.

A degasser is a device used in the upstream oil industry to remove dissolved and entrained gases from a liquid. In drilling it is used to remove gasses from drilling fluid which could otherwise form bubbles. In a produced water treatment plant it is part of the process to clean produced water prior to disposal.

Solids control is a process used in drilling rigs which use drilling fluid. It involves separating the "cuttings" from the fluid, allowing it to be recirculated or discharged to the environment.

A mud cleaner is a combination of desanders and/or desilters to remove drilled solids from mud.

Oil well control is the management of the dangerous effects caused by the unexpected release of formation fluid, such as natural gas and/or crude oil, upon surface equipment of oil or gas drilling rigs and escaping into the atmosphere. Technically, oil well control involves preventing the formation gas or fluid (hydrocarbons), usually referred to as kick, from entering into the wellbore during drilling or well interventions.