An oil platform is a large structure with facilities to extract and process petroleum and natural gas that lie in rock formations beneath the seabed. Many oil platforms will also have facilities to accommodate the workers, although it is also common to have a separate accommodation platform linked by bridge to the production platform. Most commonly, oil platforms engage in activities on the continental shelf, though they can also be used in lakes, inshore waters, and inland seas. Depending on the circumstances, the platform may be fixed to the ocean floor, consist of an artificial island, or float. In some arrangements the main facility may have storage facilities for the processed oil. Remote subsea wells may also be connected to a platform by flow lines and by umbilical connections. These sub-sea facilities may include one or more subsea wells or manifold centres for multiple wells.

Offshore construction is the installation of structures and facilities in a marine environment, usually for the production and transmission of electricity, oil, gas and other resources. It is also called maritime engineering.

A tension-leg platform (TLP) or extended tension leg platform (ETLP) is a vertically moored floating structure normally used for the offshore production of oil or gas, and is particularly suited for water depths greater than 300 metres and less than 1500 metres. Use of tension-leg platforms has also been proposed for offshore wind turbines.

In petroleum and natural gas extraction, a Christmas tree, or tree, is an assembly of valves, casing spools, and fittings used to regulate the flow of pipes in an oil well, gas well, water injection well, water disposal well, gas injection well, condensate well, and other types of well.

NOV Inc., formerly National Oilwell Varco, is an American multinational corporation based in Houston, Texas. It is a worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 500 locations across six continents, operating through two reporting segments: Energy Equipment and Energy Products and Services.

A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment.

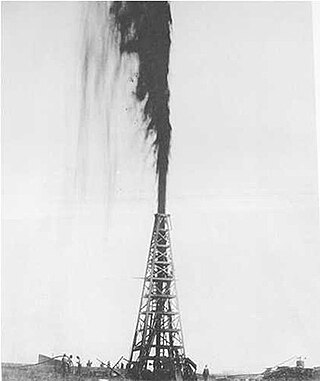

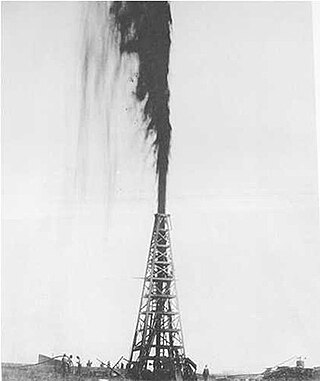

A blowout is the uncontrolled release of crude oil and/or natural gas from an oil well or gas well after pressure control systems have failed. Modern wells have blowout preventers intended to prevent such an occurrence. An accidental spark during a blowout can lead to a catastrophic oil or gas fire.

A blowout preventer (BOP) is a specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves.

In the oil and gas industry, coiled tubing refers to a long metal pipe, normally 1 to 3.25 in in diameter which is supplied spooled on a large reel. It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the drilling derrick on the oil platform, which is used to support the surface equipment, although on platforms with no drilling facilities a self-supporting tower can be used instead. For coiled tubing operations on sub-sea wells a mobile offshore drilling unit (MODU) e.g. semi-submersible, drillship etc. has to be utilized to support all the surface equipment and personnel, whereas wireline can be carried out from a smaller and cheaper intervention vessel. Onshore, they can be run using smaller service rigs, and for light operations a mobile self-contained coiled tubing rig can be used.

A well intervention, or well work, is any operation carried out on an oil or gas well during, or at the end of, its productive life that alters the state of the well or well geometry, provides well diagnostics, or manages the production of the well.

Deepwater drilling, or deep well drilling, is the process of creating holes in the Earth's crust using a drilling rig for oil extraction under the deep sea. There are approximately 3400 deepwater wells in the Gulf of Mexico with depths greater than 150 meters.

A conductor Pipe is a large diameter pipe that is set into the ground to provide the initial stable structural foundation for a borehole or oil well. The Conductor pipe is the first string of casing and is the largest diameter casing to be installed in a well. It can also be referred to as a drive pipe because it is often driven into the ground with a pile driver.

Discoverer Enterprise is a fifth generation deepwater double hulled dynamically positioned drillship owned and operated by Transocean Offshore Deepwater Drilling Inc., capable of operating in moderate environments and water depths up to 3,049 m (10,000 ft) using an 18.75 in (47.6 cm), 15,000 psi blowout preventer (BOP), and a 21 in (53 cm) outside diameter (OD) marine riser. From 1998 to 2005 the vessel was Panama-flagged and currently flies the flag of convenience of the Marshall Islands.

Offshore oil spill prevention and response is the study and practice of reducing the number of offshore incidents that release oil or hazardous substances into the environment and limiting the amount released during those incidents.

Commercial offshore diving, sometimes shortened to just offshore diving, generally refers to the branch of commercial diving, with divers working in support of the exploration and production sector of the oil and gas industry in places such as the Gulf of Mexico in the United States, the North Sea in the United Kingdom and Norway, and along the coast of Brazil. The work in this area of the industry includes maintenance of oil platforms and the building of underwater structures. In this context "offshore" implies that the diving work is done outside of national boundaries. Technically it also refers to any diving done in the international offshore waters outside of the territorial waters of a state, where national legislation does not apply. Most commercial offshore diving is in the Exclusive Economic Zone of a state, and much of it is outside the territorial waters. Offshore diving beyond the EEZ does also occur, and is often for scientific purposes.

An Emergency Disconnect Package (EDP) is a piece of equipment used in the drilling and work-over of deep sea oil & gas wells, by Mobile Offshore Drilling Rigs (MODU's) and Well Intervention Vessels (WIV's). The EDP is designed for use in an emergency, when the MODU or WIV needs to quickly disconnect, and move away from the oil/gas well that it is drilling or working-over. Examples of when this might be necessary include unexpected extreme weather that exceeds the MODU/Vessel's capability to maintain its position.

The Helix fast-response system (HFRS) is a deep-sea oil spill response plan licensed by HWCG LLC, a consortium of 16 independent oil companies, to respond to subsea well incidents. Helix Energy Solutions Group designed the Helix fast-response system based on techniques used to contain the 2010 Gulf of Mexico oil spill. On February 28, 2011 the drilling moratorium imposed as a result of the spill ended when the United States Department of the Interior approved the first drilling permit based on the availability of the HFRS to offshore oil companies.

A submarine pipeline is a pipeline that is laid on the seabed or below it inside a trench. In some cases, the pipeline is mostly on-land but in places it crosses water expanses, such as small seas, straits and rivers. Submarine pipelines are used primarily to carry oil or gas, but transportation of water is also important. A distinction is sometimes made between a flowline and a pipeline. The former is an intrafield pipeline, in the sense that it is used to connect subsea wellheads, manifolds and the platform within a particular development field. The latter, sometimes referred to as an export pipeline, is used to bring the resource to shore. Sizeable pipeline construction projects need to take into account many factors, such as the offshore ecology, geohazards and environmental loading – they are often undertaken by multidisciplinary, international teams.

A hot stab is a type of subsea connector specifically designed to be easily inserted and removed by a remotely operated underwater vehicle (ROV) manipulator arm. The hot stab is the connector which supplies remote utilities. It is normally inserted into a port after removing the plug stab, which is left in the port when the hot stab is disconnected, to keep the port clean and free of fouling when not in use. The alignment is generally not critical for insertion, and the stab is guided into the port by the port geometry, which tends to be concentric cylinder and cone sections, tapering down from the handle end to the tip, with a series of O-ring seals separating the ports or contacts spaced along the length. The stab may be locked into place or may require the ROV to hold it in place while it is in use.