Laminar flow is the property of fluid particles in fluid dynamics to follow smooth paths in layers, with each layer moving smoothly past the adjacent layers with little or no mixing. At low velocities, the fluid tends to flow without lateral mixing, and adjacent layers slide past one another smoothly. There are no cross-currents perpendicular to the direction of flow, nor eddies or swirls of fluids. In laminar flow, the motion of the particles of the fluid is very orderly with particles close to a solid surface moving in straight lines parallel to that surface. Laminar flow is a flow regime characterized by high momentum diffusion and low momentum convection.

In thermal fluid dynamics, the Nusselt number is the ratio of total heat transfer to conductive heat transfer at a boundary in a fluid. Total heat transfer combines conduction and convection. Convection includes both advection and diffusion (conduction). The conductive component is measured under the same conditions as the convective but for a hypothetically motionless fluid. It is a dimensionless number, closely related to the fluid's Rayleigh number.

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

In thermodynamics, the heat transfer coefficient or film coefficient, or film effectiveness, is the proportionality constant between the heat flux and the thermodynamic driving force for the flow of heat. It is used in calculating the heat transfer, typically by convection or phase transition between a fluid and a solid. The heat transfer coefficient has SI units in watts per square meter per kelvin (W/m2K).

A falling film evaporator is an industrial device to concentrate solutions, especially with heat sensitive components. The evaporator is a special type of heat exchanger.

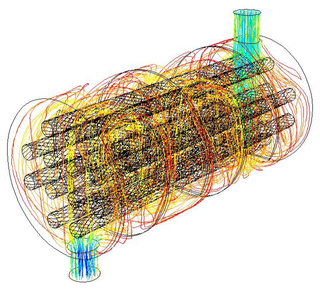

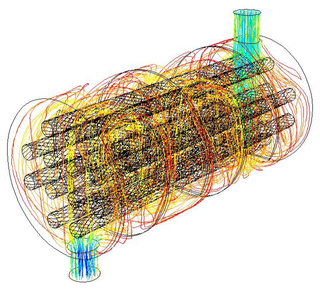

A shell-and-tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc.

Fouling is the accumulation of unwanted material on solid surfaces. The fouling materials can consist of either living organisms or a non-living substance (inorganic). Fouling is usually distinguished from other surface-growth phenomena in that it occurs on a surface of a component, system, or plant performing a defined and useful function and that the fouling process impedes or interferes with this function.

In fluid dynamics, the Schmidt number of a fluid is a dimensionless number defined as the ratio of momentum diffusivity and mass diffusivity, and it is used to characterize fluid flows in which there are simultaneous momentum and mass diffusion convection processes. It was named after German engineer Ernst Heinrich Wilhelm Schmidt (1892–1975).

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. Plate heat exchangers are now common and very small brazed versions are used in the hot-water sections of millions of combination boilers. The high heat transfer efficiency for such a small physical size has increased the domestic hot water (DHW) flowrate of combination boilers. The small plate heat exchanger has made a great impact in domestic heating and hot-water. Larger commercial versions use gaskets between the plates, whereas smaller versions tend to be brazed.

An evaporator is a type of heat exchanger device that facilitates evaporation by utilizing conductive and convective heat transfer, which provides the necessary thermal energy for phase transition from liquid to vapour. Within evaporators, a circulating liquid is exposed to an atmospheric or reduced pressure environment causing it to boil at a lower temperature compared to normal atmospheric boiling.

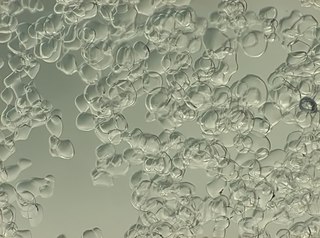

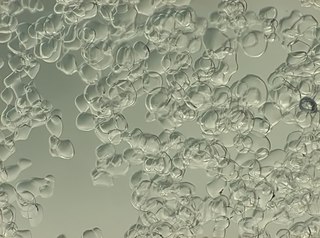

Slurry ice is a phase changing refrigerant made up of millions of ice "micro-crystals" formed and suspended within a solution of water and a freezing point depressant. Some compounds used in the field are salt, ethylene glycol, propylene glycol, alcohols like isobutyl and ethanol, and sugars like sucrose and glucose. Slurry ice has greater heat absorption compared to single phase refrigerants like brine, because the melting enthalpy of the ice is also used.

Continuous reactors carry material as a flowing stream. Reactants are continuously fed into the reactor and emerge as continuous stream of product. Continuous reactors are used for a wide variety of chemical and biological processes within the food, chemical and pharmaceutical industries. A survey of the continuous reactor market will throw up a daunting variety of shapes and types of machine. Beneath this variation however lies a relatively small number of key design features which determine the capabilities of the reactor. When classifying continuous reactors, it can be more helpful to look at these design features rather than the whole system.

Concentric Tube Heat Exchangers are used in a variety of industries for purposes such as material processing, food preparation, and air-conditioning. They create a temperature driving force by passing fluid streams of different temperatures parallel to each other, separated by a physical boundary in the form of a pipe. This induces forced convection, transferring heat to/from the product.

In chemical engineering, a jacketed vessel is a container that is designed for controlling temperature of its contents, by using a cooling or heating "jacket" around the vessel through which a cooling or heating fluid is circulated.

In fluid dynamics, the process of a laminar flow becoming turbulent is known as laminar–turbulent transition. The main parameter characterizing transition is the Reynolds number.

In fluid dynamics, the Reynolds number is a dimensionless quantity that helps predict fluid flow patterns in different situations by measuring the ratio between inertial and viscous forces. At low Reynolds numbers, flows tend to be dominated by laminar (sheet-like) flow, while at high Reynolds numbers, flows tend to be turbulent. The turbulence results from differences in the fluid's speed and direction, which may sometimes intersect or even move counter to the overall direction of the flow. These eddy currents begin to churn the flow, using up energy in the process, which for liquids increases the chances of cavitation.

Pumpable icetechnology (PIT) uses thin liquids, with the cooling capacity of ice. Pumpable ice is typically a slurry of ice crystals or particles ranging from 5 micrometers to 1 cm in diameter and transported in brine, seawater, food liquid, or gas bubbles of air, ozone, or carbon dioxide.

Circulation evaporators are a type of evaporating unit designed to separate mixtures unable to be evaporated by a conventional evaporating unit. Circulation evaporation incorporates the use of both heat exchangers and flash separation units in conjunction with circulation of the solvent in order to remove liquid mixtures without conventional boiling. There are two types of Circulation Evaporation; Natural Circulation Evaporators and Forced Circulation Evaporators, both of which are still currently used in industry today, although forced Circulation systems, which have a circulation pump as opposed to natural systems with no driving force, have a much wider range of appropriate uses.

A rising film or vertical long tube evaporator is a type of evaporator that is essentially a vertical shell and tube heat exchanger. The liquid being evaporated is fed from the bottom into long tubes and heated with steam condensing on the outside of the tube from the shell side. This is to produce steam and vapour within the tube bringing the liquid inside to a boil. The vapour produced then presses the liquid against the walls of the tubes and causes the ascending force of this liquid. As more vapour is formed, the centre of the tube will have a higher velocity which forces the remaining liquid against the tube wall forming a thin film which moves upwards. This phenomenon of the rising film gives the evaporator its name.

Biofluid dynamics may be considered as the discipline of biological engineering or biomedical engineering in which the fundamental principles of fluid dynamics are used to explain the mechanisms of biological flows and their interrelationships with physiological processes, in health and in diseases/disorder. It can be considered as the conjuncture of mechanical engineering and biological engineering. It spans from cells to organs, covering diverse aspects of the functionality of systemic physiology, including cardiovascular, respiratory, reproductive, urinary, musculoskeletal and neurological systems etc. Biofluid dynamics and its simulations in computational fluid dynamics (CFD) apply to both internal as well as external flows. Internal flows such as cardiovascular blood flow and respiratory airflow, and external flows such as flying and aquatic locomotion. Biological fluid Dynamics involves the study of the motion of biological fluids. It can be either circulatory system or respiratory systems. Understanding the circulatory system is one of the major areas of research. The respiratory system is very closely linked to the circulatory system and is very complex to study and understand. The study of Biofluid Dynamics is also directed towards finding solutions to some of the human body related diseases and disorders. The usefulness of the subject can also be understood by seeing the use of Biofluid Dynamics in the areas of physiology in order to explain how living things work and about their motions, in developing an understanding of the origins and development of various diseases related to human body and diagnosing them, in finding the cure for the diseases related to cardiovascular and pulmonary systems.