Related Research Articles

Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the properties it had in its original state. It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution and water pollution.

System dynamics (SD) is an approach to understanding the nonlinear behaviour of complex systems over time using stocks, flows, internal feedback loops, table functions and time delays.

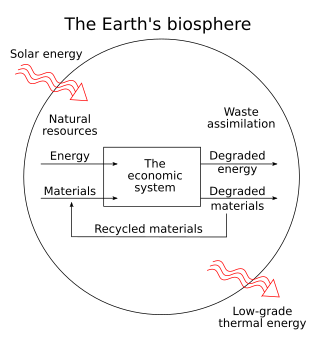

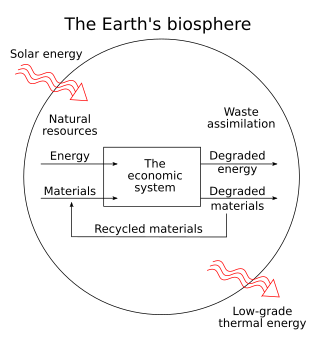

Industrial ecology (IE) is the study of material and energy flows through industrial systems. The global industrial economy can be modelled as a network of industrial processes that extract resources from the Earth and transform those resources into by-products, products and services which can be bought and sold to meet the needs of humanity. Industrial ecology seeks to quantify the material flows and document the industrial processes that make modern society function. Industrial ecologists are often concerned with the impacts that industrial activities have on the environment, with use of the planet's supply of natural resources, and with problems of waste disposal. Industrial ecology is a young but growing multidisciplinary field of research which combines aspects of engineering, economics, sociology, toxicology and the natural sciences.

Life cycle assessment (LCA), also known as life cycle analysis, is a methodology for assessing environmental impacts associated with all the stages of the life cycle of a commercial product, process, or service. For instance, in the case of a manufactured product, environmental impacts are assessed from raw material extraction and processing (cradle), through the product's manufacture, distribution and use, to the recycling or final disposal of the materials composing it (grave).

The recycling of paper is the process by which waste paper is turned into new paper products. It has a number of important benefits: It saves waste paper from occupying homes of people and producing methane as it breaks down. Because paper fibre contains carbon, recycling keeps the carbon locked up for longer and out of the atmosphere. Around two-thirds of all paper products in the US are now recovered and recycled, although it does not all become new paper. After repeated processing the fibres become too short for the production of new paper, which is why virgin fibre is frequently added to the pulp recipe.

Downcycling, or cascading, is the recycling of waste where the recycled material is of lower quality and functionality than the original material. Often, this is due to the accumulation of tramp elements in secondary metals, which may exclude the latter from high-quality applications. For example, steel scrap from end-of-life vehicles is often contaminated with copper from wires and tin from coating. This contaminated scrap yields a secondary steel that does not meet the specifications for automotive steel and therefore, it is mostly applied in the construction sector.

Material efficiency is a description or metric ((Mp) (the ratio of material used to the supplied material)) which refers to decreasing the amount of a particular material needed to produce a specific product. Making a usable item out of thinner stock than a prior version increases the material efficiency of the manufacturing process. Material efficiency is associated with Green building and Energy conservation, as well as other ways of incorporating Renewable resources in the building process from start to finish.

Robert Underwood Ayres was an American-born physicist and economist. His career focused on the application of physical ideas, especially the laws of thermodynamics, to economics; a long-standing pioneering interest in material flows and transformations —a concept which he originated. His most recent work challenged the widely held economic theory of growth.

Material flow analysis (MFA), also referred to as substance flow analysis (SFA), is an analytical method to quantify flows and stocks of materials or substances in a well-defined system. MFA is an important tool to study the bio-physical aspects of human activity on different spatial and temporal scales. It is considered a core method of industrial ecology or anthropogenic, urban, social and industrial metabolism. MFA is used to study material, substance, or product flows across different industrial sectors or within ecosystems. MFA can also be applied to a single industrial installation, for example, for tracking nutrient flows through a waste water treatment plant. When combined with an assessment of the costs associated with material flows this business-oriented application of MFA is called material flow cost accounting. MFA is an important tool to study the circular economy and to devise material flow management. Since the 1990s, the number of publications related to material flow analysis has grown steadily. Peer-reviewed journals that publish MFA-related work include the Journal of Industrial Ecology, Ecological Economics, Environmental Science and Technology, and Resources, Conservation, and Recycling.

Material flow management (MFM) is an economic focused method of analysis and reformation of goods production and subsequent waste through the lens of material flows, incorporating themes of sustainability and the theory of a circular economy. It is used in social, medical, and urban contexts. However, MFM has grown in the field of industrial ecology, combining both technical and economic approaches to minimize waste that impacts economic prosperity and the environment. It has been heavily utilized by the country of Germany, but it has been applied to the industries of various other countries. The material flow management process utilizes the Sankey diagram, and echoes the circular economy model, while being represented in media environments as a business model which may help lower the costs of production and waste.

Material flow accounting (MFA) is the study of material flows on a national or regional scale. It is therefore sometimes also referred to as regional, national or economy-wide material flow analysis.

The establishment of industrial ecology as field of scientific research is commonly attributed to an article devoted to industrial ecosystems, written by Frosch and Gallopoulos, which appeared in a 1989 special issue of Scientific American. Industrial ecology emerged from several earlier ideas and concepts, some of which date back to the 19th century.

Urban metabolism (UM) is a model to facilitate the description and analysis of the flows of the materials and energy within cities, such as undertaken in a material flow analysis of a city. It provides researchers with a metaphorical framework to study the interactions of natural and human systems in specific regions. From the beginning, researchers have tweaked and altered the parameters of the urban metabolism model. C. Kennedy and fellow researchers have produced a clear definition in the 2007 paper The Changing Metabolism of Cities claiming that urban metabolism is "the sum total of the technical and socio-economic process that occur in cities, resulting in growth, production of energy and elimination of waste." With the growing concern of climate change and atmospheric degradation, the use of the urban metabolism model has become a key element in determining and maintaining levels of sustainability and health in cities around the world. Urban metabolism provides a unified or holistic viewpoint to encompass all of the activities of a city in a single model.

Economy-wide material flow accounts (EW-MFA) is a framework to compile statistics linking flows of materials from natural resources to a national economy. EW-MFA are descriptive statistics, in physical units such as tonnes per year.

A circular economy is a model of resource production and consumption in any economy that involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products for as long as possible. The concept aims to tackle global challenges such as climate change, biodiversity loss, waste, and pollution by emphasizing the design-based implementation of the three base principles of the model. The main three principles required for the transformation to a circular economy are: designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. CE is defined in contradistinction to the traditional linear economy.

Social metabolism or socioeconomic metabolism is the set of flows of materials and energy that occur between nature and society, between different societies, and within societies. These human-controlled material and energy flows are a basic feature of all societies but their magnitude and diversity largely depend on specific cultures, or sociometabolic regimes. Social or socioeconomic metabolism is also described as "the self-reproduction and evolution of the biophysical structures of human society. It comprises those biophysical transformation processes, distribution processes, and flows, which are controlled by humans for their purposes. The biophysical structures of society and socioeconomic metabolism together form the biophysical basis of society."

Resource recovery is using wastes as an input material to create valuable products as new outputs. The aim is to reduce the amount of waste generated, thereby reducing the need for landfill space, and optimising the values created from waste. Resource recovery delays the need to use raw materials in the manufacturing process. Materials found in municipal solid waste, construction and demolition waste, commercial waste and industrial wastes can be used to recover resources for the manufacturing of new materials and products. Plastic, paper, aluminium, glass and metal are examples of where value can be found in waste.

Environmentally extended input–output analysis (EEIOA) is used in environmental accounting as a tool which reflects production and consumption structures within one or several economies. As such, it is becoming an important addition to material flow accounting.

A circular economy is an alternative way countries manage their resources, in which usage of products in the traditional linear make, use, and dispose method is not implemented. Instead, resources are used for their maximum utility throughout their life cycle and regenerated in a cyclical pattern minimizing waste. They strive to create economic development through environmental and resource protection. The ideas of a circular economy were officially adopted by China in 2002, when the 16th National Congress of the Chinese Communist Party legislated it as a national endeavor though the various sustainability initiatives which were implemented in the previous decades starting in 1973. China adopted the circular economy due to the environmental damage and resource depletion that was occurring from going through its industrialization process. China is currently a world leader in the production of resources, where it produces 46% of the world's aluminum, 50% of steel and 60% of cement, while it has consumed more raw materials than all the countries a part of the Organisation for Economic Co-operation and Development (OECD) combined. In 2014, China created 3.2 billion tonnes of industrial solid waste, where 2 billion tonnes were recovered using recycling, incineration, reusing and composting. By 2025, China is anticipated to produce up to one quarter of the world's municipal solid waste.

The Waste Input-Output (WIO) model is an innovative extension of the environmentally extended input-output (EEIO) model. It enhances the traditional Input-Output (IO) model by incorporating physical waste flows generated and treated alongside monetary flows of products and services. In a WIO model, each waste flow is traced from its generation to its treatment, facilitated by an allocation matrix. Additionally, the model accounts for the transformation of waste during treatment into secondary waste and residues, as well as recycling and final disposal processes. By including the end-of-life (EoL) stage of products, the WIO model enables a comprehensive consideration of the entire product life cycle, encompassing production, use, and disposal stages within the IO analysis framework. As such, it serves as a valuable tool for life cycle assessment (LCA).

References

- ↑ Pauliuk, Stefan; Müller, Daniel B. (2014). "The role of in-use stocks in the social metabolism and in climate change mitigation". Global Environmental Change. 24: 132–42. doi:10.1016/j.gloenvcha.2013.11.006. hdl: 11250/2367975 .

- 1 2 Müller, Esther; Hilty, Lorenz M.; Widmer, Rolf; Schluep, Mathias; Faulstich, Martin (2014). "Modeling Metal Stocks and Flows: A Review of Dynamic Material Flow Analysis Methods". Environmental Science & Technology. 48 (4): 2102–13. Bibcode:2014EnST...48.2102M. doi:10.1021/es403506a. PMID 24494583.

- ↑ Elshkaki, A (2005). "Dynamic stock modelling: A method for the identification and estimation of future waste streams and emissions based on past production and product stock characteristics". Energy. 30 (8): 1353–63. doi:10.1016/j.energy.2004.02.019.

- ↑ Van Der Voet, Ester; Kleijn, René; Huele, Ruben; Ishikawa, Masanobu; Verkuijlen, Evert (2002). "Predicting future emissions based on characteristics of stocks". Ecological Economics. 41 (2): 223–34. doi:10.1016/S0921-8009(02)00028-9.

- ↑ b. Müller, Daniel (2006). "Stock dynamics for forecasting material flows—Case study for housing in the Netherlands". Ecological Economics. 59: 142–56. doi:10.1016/j.ecolecon.2005.09.025.