Related Research Articles

A simulation is an approximate imitation of the operation of a process or system; that represents its operation over time.

In computer engineering, a hardware description language (HDL) is a specialized computer language used to describe the structure and behavior of electronic circuits, and most commonly, digital logic circuits.

Computer simulation is the process of mathematical modelling, performed on a computer, which is designed to predict the behaviour of or the outcome of a real-world or physical system. Since they allow to check the reliability of chosen mathematical models, computer simulations have become a useful tool for the mathematical modeling of many natural systems in physics, astrophysics, climatology, chemistry, biology and manufacturing, as well as human systems in economics, psychology, social science, health care and engineering. Simulation of a system is represented as the running of the system's model. It can be used to explore and gain new insights into new technology and to estimate the performance of systems too complex for analytical solutions.

In computer network research, network simulation is a technique whereby a software program models the behavior of a network by calculating the interaction between the different network entities. Most simulators use discrete event simulation - the modeling of systems in which state variables change at discrete points in time. The behavior of the network and the various applications and services it supports can then be observed in a test lab; various attributes of the environment can also be modified in a controlled manner to assess how the network / protocols would behave under different conditions.

Modelica is an object-oriented, declarative, multi-domain modeling language for component-oriented modeling of complex systems, e.g., systems containing mechanical, electrical, electronic, hydraulic, thermal, control, electric power or process-oriented subcomponents. The free Modelica language is developed by the non-profit Modelica Association. The Modelica Association also develops the free Modelica Standard Library that contains about 1360 generic model components and 1280 functions in various domains, as of version 3.2.1.

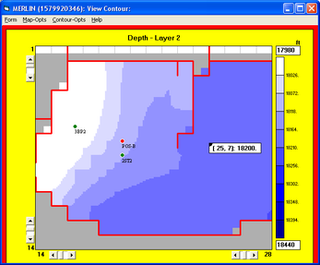

Reservoir simulation is an area of reservoir engineering in which computer models are used to predict the flow of fluids through porous media.

ASCEND is an open source, mathematical modelling chemical process modelling system developed at Carnegie Mellon University since late 1978. ASCEND is an acronym which stands for Advanced System for Computations in Engineering Design. Its main uses have been in the field of chemical process modelling although its capabilities are general.

The COCO Simulator is a free-of-charge, non-commercial, graphical, modular and CAPE-OPEN compliant, steady-state, sequential simulation process modeling environment. It was originally intended as a test environment for CAPE-OPEN modeling tools but now provides free chemical process simulation for students. It is an open flowsheet modeling environment allowing anyone to add new unit operations or thermodynamics packages.

Simulation software is based on the process of modeling a real phenomenon with a set of mathematical formulas. It is, essentially, a program that allows the user to observe an operation through simulation without actually performing that operation. Simulation software is used widely to design equipment so that the final product will be as close to design specs as possible without expensive in process modification. Simulation software with real-time response is often used in gaming, but it also has important industrial applications. When the penalty for improper operation is costly, such as airplane pilots, nuclear power plant operators, or chemical plant operators, a mock up of the actual control panel is connected to a real-time simulation of the physical response, giving valuable training experience without fear of a disastrous outcome.

MapleSim is a Modelica-based, multi-domain modeling and simulation tool developed by Maplesoft. MapleSim generates model equations, runs simulations, and performs analyses using the symbolic and numeric mathematical engine of Maple. Models are created by dragging-and-dropping components from a library into a central workspace, resulting in a model that represents the physical system in a graphical form. Maplesoft began development of MapleSim partly in response to a request from Toyota to produce physical modeling tools to aid in their new model-based development process.

Pantelides algorithm gives a systematic method for reducing high-index systems of differential-algebraic equations to lower index, by selectively adding differentiated forms of the equations already present in the system. It is possible for the algorithm to fail in some instances.

Process simulation is used for the design, development, analysis, and optimization of technical processes such as: chemical plants, chemical processes, environmental systems, power stations, complex manufacturing operations, biological processes, and similar technical functions.

Human-in-the-loop or HITL is defined as a model that requires human interaction. HITL is associated with modeling and simulation (M&S) in the live, virtual, and constructive taxonomy. HITL models may conform to human factors requirements as in the case of a mockup. In this type of simulation a human is always part of the simulation and consequently influences the outcome in such a way that is difficult if not impossible to reproduce exactly. HITL also readily allows for the identification of problems and requirements that may not be easily identified by other means of simulation.

PRO/II from the AVEVA SimSci brand is a steady-state process simulator for process design and operational analysis for process engineers in the chemical, petroleum, natural gas, solids processing, and polymer industries.

MLDesigner is an integrated modeling and simulation tool for the design and analysis of complex embedded and networked systems. MLDesigner speeds up modeling, simulation and analysis of discrete event, discrete time and continuous time systems concerning architecture, function and performance. The tools is based on ideas of the "Ptolemy Project", done at the University if California Berkeley. MLDesigner is developed by MLDesign Technologies Inc. Palo Alto, CA, USA in collaboration with Mission Level Design GmbH, Ilmenau, Germany.

COPASI is an open-source software application for creating and solving mathematical models of biological processes such as metabolic networks, cell-signaling pathways, regulatory networks, infectious diseases, and many others.

Artificial life is a field of study wherein researchers examine systems related to natural life, its processes, and its evolution, through the use of simulations with computer models, robotics, and biochemistry. The discipline was named by Christopher Langton, an American theoretical biologist, in 1986. In 1987 Langton organized the first conference on the field, in Los Alamos, New Mexico. There are three main kinds of alife, named for their approaches: soft, from software; hard, from hardware; and wet, from biochemistry. Artificial life researchers study traditional biology by trying to recreate aspects of biological phenomena.

Aspen Plus, Aspen HYSYS, ChemCad and MATLAB, PRO are the commonly used process simulators for modeling, simulation and optimization of a distillation process in the chemical industries. Distillation is the technique of preferential separation of the more volatile component (s) from the less volatile ones in a feed followed by condensation.The vapor produced is richer in the more volatile components(s). The distribution of the component in the two phase is governed by the vapour-liquid equilibrium relationship. In practice, distillation may be carried out by either two principal methods. The first method is based on the production of vapor boiling the liquid mixture to be separated and condensing the vapors without allowing any liquid to return to the still. There is no reflux. The second method is based on the return of part of the condensate to still under such conditions that this returning liquid is brought into intimate contact with the vapors on their way to condenser.

The CAPE-OPEN Interface Standard consists of a series of specifications to expand the range of application of process simulation technologies. The CAPE-OPEN specifications define a set of software interfaces that allow plug and play inter-operability between a given Process Modelling Environment and a third-party Process Modelling Component.

References

- ↑ R. P. Soares and A. R. Secchi, EMSO: A new environment for modelling, simulation and optimisation, Computer Aided Chemical Engineering, 14, (2003), 947-952. DOI: 10.1016/S1570-7946(03)80239-0

- ↑ http://www.vrtech.com.br/rps/emso.html Archived 2011-07-06 at the Wayback Machine , EMSO page, Retrieved 7/4/2010