The ecological footprint is a method promoted by the Global Footprint Network to measure human demand on natural capital, i.e. the quantity of nature it takes to support people or an economy. It tracks this demand through an ecological accounting system. The accounts contrast the biologically productive area people use for their consumption to the biologically productive area available within a region or the world. In short, it is a measure of human impact on the environment.

Life cycle assessment or LCA is a methodology for assessing environmental impacts associated with all the stages of the life cycle of a commercial product, process, or service. For instance, in the case of a manufactured product, environmental impacts are assessed from raw material extraction and processing (cradle), through the product's manufacture, distribution and use, to the recycling or final disposal of the materials composing it (grave).

Eco-capitalism, also known as environmental capitalism or (sometimes) green capitalism, is the view that capital exists in nature as "natural capital" on which all wealth depends. Therefore, governments should use market-based policy-instruments to resolve environmental problems.

Over the years, as countries and regions around the world began to develop, it slowly became evident that industrialization and economic growth come hand in hand with environmental degradation. Eco-efficiency has been proposed as one of the main tools to promote a transformation from unsustainable development to one of sustainable development. It is based on the concept of creating more goods and services while using fewer resources and creating less waste and pollution. "It is measured as the ratio between the (added) value of what has been produced and the (added) environment impacts of the product or service ." The term was coined by the World Business Council for Sustainable Development (WBCSD) in its 1992 publication "Changing Course," and at the 1992 Earth Summit, eco-efficiency was endorsed as a new business concept and means for companies to implement Agenda 21 in the private sector. Ergo the term has become synonymous with a management philosophy geared towards sustainability, combining ecological and economic efficiency.

A sustainable business, or a green business, is an enterprise that has minimal negative impact or potentially a positive effect on the global or local environment, community, society, or economy—a business that strives to meet the triple bottom line. They cluster under different groupings and the whole is sometimes referred to as "green capitalism." Often, sustainable businesses have progressive environmental and human rights policies. In general, business is described as green if it matches the following four criteria:

- It incorporates principles of sustainability into each of its business decisions.

- It supplies environmentally friendly products or services that replaces demand for nongreen products and/or services.

- It is greener than traditional competition.

- It has made an enduring commitment to environmental principles in its business operations.

A carbon footprint is the total greenhouse gas (GHG) emissions caused by an individual, event, organization, service, place or product, expressed as carbon dioxide equivalent. Greenhouse gases, including the carbon-containing gases carbon dioxide and methane, can be emitted through the burning of fossil fuels, land clearance and the production and consumption of food, manufactured goods, materials, wood, roads, buildings, transportation and other services. The term was popularized by a $250 million advertising campaign by the oil and gas company BP in an attempt to move public attention away from restricting the activities of fossil fuel companies and onto individual responsibility for solving climate change.

An environmental management system (EMS) is "a system and database which integrates procedures and processes for training of personnel, monitoring, summarizing, and reporting of specialized environmental performance information to internal and external stakeholders of a firm".

Carbon accounting or greenhouse gas accounting refers to processes used to measure how much carbon dioxide equivalents an organization emits. It is used by states, corporations, and individuals to create the carbon credit commodity traded on carbon markets. Examples of products based on forms of carbon accounting may be found in national inventories, corporate environmental reports, and carbon footprint calculators.

Ecological design or ecodesign is an approach to designing products and services with special consideration for the environmental impacts of the product during its whole lifecycle. It was defined by Sim Van der Ryn and Stuart Cowan as "any form of design that minimizes environmentally destructive impacts by integrating itself with living processes." Ecological design is an integrative ecologically responsible design discipline. Ecological design can also be defined as the process within design and development of integration of environmental consideration into product and service design and development with the aim of reducing environmental impacts of products through their life cycle.

Material input per unit of service (MIPS) is an economic concept, originally developed at the Wuppertal Institute, Germany in the 1990s. The MIPS concept can be used to measure eco-efficiency of a product or service and applied in all scales from a single product to complex systems. The calculation takes into account materials required to produce a product or service. The total material input (MI) is divided by the number of service units (S). For example, in case of a passenger car, the number of service units is the total number of passenger kilometres during the whole life span of the vehicle. The lower the material input per kilometre, the more eco-efficient is the vehicle. The whole life-cycle of a product or service is measured when MIPS values are calculated. This allows comparisons of resource consumption of different solutions to produce the same service. When a single product is examined, the MIPS calculations reveal the magnitude of resource use along the life-cycle and help to focus efforts on the most significant phases to reduce environmental burden of the product.

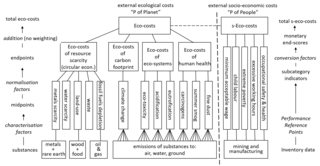

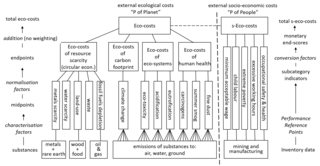

Eco-costs are the costs of the environmental burden of a product on the basis of prevention of that burden. They are the costs which should be made to reduce the environmental pollution and materials depletion in our world to a level which is in line with the carrying capacity of our earth.

The EVR model is a life cycle assessment based method to analyse consumption patterns, business strategies and design options in terms of eco-efficient value creation. Next to this it is used to compare products and service systems.

Prospective Outlook on Long-term Energy Systems (POLES) is a world simulation model for the energy sector that runs on the Vensim software. It is a techno-economic model with endogenous projection of energy prices, a complete accounting of energy demand and supply of numerous energy vectors and associated technologies, and a carbon dioxide and other greenhouse gases emissions module.

Ecometrics is the quantitative analysis of economic, environmental, and societal systems based on the concurrent development of empirical theory, related by appropriate methods of inference in attempts to create more sustainable systems. Broadly defined, Ecometrics is a way to evaluate if an activity is contributing to more sustainable systems of production and consumption. Ecometrics is a system of statistical extrapolation and interpolation that uses principles of resource management in economic and environmental studies to analyze trends in consumption. With a comprehensive understanding of ecometrics, and thereby an understanding of the impacts of specific conscious or conventional opportunity costs, agents within economic systems can cause measurable change for the triple bottom line. The term was originally trademarked by Interface Global, a corporation founded by Ray Anderson. The parameters that cause change are often population, technology, transportation, consumption, public conscious, non-renewable or renewable resources, location, labor conditions, transportation and wealth. Ecometrics is used in labeling programs such as the US EPA Fuel Economy and Environment Label to determine the environmental and financial advantages of purchasing one car over another. There are many applications of Ecometrics for Environmental Impact Calculators infographics, and for political analysis. Because the parameters of ecometrics vary drastically for any activity, the applications of its resulting measurements are sometimes unilateral. Applied ecometrics exposes the complexity of making sustainable decisions, especially given other humanitarian goals such as third world economic development. In this way ecometrics shows any choice within consumption and production systems as wicked problems.

Zero-carbon housing and zero-energy housing are terms used interchangeably to define single family dwellings with a very high energy efficiency rating. Zero-energy housing requires a very low amount of energy to provide the daily needs and functions for the family occupying the home.

Hans Ronald "Harold" Krikke is a widely recognized scientist in Closed Loop Supply Chains.

Resource efficiency is the maximising of the supply of money, materials, staff, and other assets that can be drawn on by a person or organization in order to function effectively, with minimum wasted (natural) resource expenses. It means using the Earth's limited resources in a sustainable manner while minimising environmental impact.

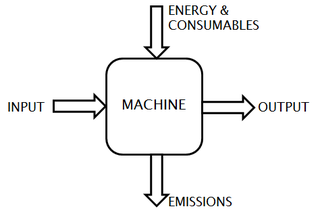

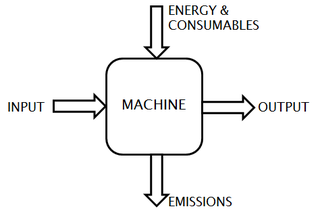

Ecomechatronics is an engineering approach to developing and applying mechatronical technology in order to reduce the ecological impact and total cost of ownership of machines. It builds upon the integrative approach of mechatronics, but not with the aim of only improving the functionality of a machine. Mechatronics is the multidisciplinary field of science and engineering that merges mechanics, electronics, control theory, and computer science to improve and optimize product design and manufacturing. In ecomechatronics, additionally, functionality should go hand in hand with an efficient use and limited impact on resources. Machine improvements are targeted in 3 key areas: energy efficiency, performance and user comfort.

Environmentally extended input-output analysis (EEIOA) is used in environmental accounting as a tool which reflects production and consumption structures within one or several economies. As such, it is becoming an important addition to material flow accounting.

Environmental systems analysis (ESA) is a systematic and systems based approach for describing human actions impacting on the natural environment to support decisions and actions aimed at perceived current or future environmental problems. Impacts of different types of objects are studied that ranges from projects, programs and policies, to organizations, and products. Environmental systems analysis encompasses a family of environmental assessment tools and methods, including life cycle assessment (LCA), material flow analysis (MFA) and substance flow analysis (SFA), and environmental impact assessment (EIA), among others.