Related Research Articles

An elastomer is a polymer with viscoelasticity and with weak intermolecular forces, generally low Young's modulus (E) and high failure strain compared with other materials. The term, a portmanteau of elastic polymer, is often used interchangeably with rubber, although the latter is preferred when referring to vulcanisates. Each of the monomers which link to form the polymer is usually a compound of several elements among carbon, hydrogen, oxygen and silicon. Elastomers are amorphous polymers maintained above their glass transition temperature, so that considerable molecular reconformation is feasible without breaking of covalent bonds. At ambient temperatures, such rubbers are thus relatively compliant and deformable. Their primary uses are for seals, adhesives and molded flexible parts.

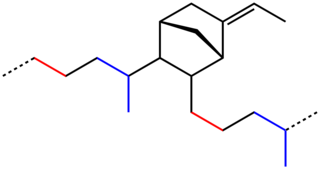

EPDM rubber is a type of synthetic rubber that is used in many applications. Dienes used in the manufacture of EPDM rubbers are ethylidene norbornene (ENB), dicyclopentadiene (DCPD), and vinyl norbornene (VNB). 4-8% of these monomers are typically used.

Butyl rubber, sometimes just called "butyl", is a synthetic rubber, a copolymer of isobutylene with isoprene. The abbreviation IIR stands for isobutylene isoprene rubber. Polyisobutylene, also known as "PIB" or polyisobutene, (C4H8)n, is the homopolymer of isobutylene, or 2-methyl-1-propene, on which butyl rubber is based. Butyl rubber is produced by polymerization of about 98% of isobutylene with about 2% of isoprene. Structurally, polyisobutylene resembles polypropylene, but has two methyl groups substituted on every other carbon atom, rather than one. Polyisobutylene is a colorless to light yellow viscoelastic material. It is generally odorless and tasteless, though it may exhibit a slight characteristic odor.

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More specialized polyolefins include polyisobutylene and polymethylpentene. They are all colorless or white oils or solids. Many copolymers are known, such as polybutene, which derives from a mixture of different butene isomers. The name of each polyolefin indicates the olefin from which it is prepared; for example, polyethylene is derived from ethylene, and polymethylpentene is derived from 4-methyl-1-pentene. Polyolefins are not olefins themselves because the double bond of each olefin monomer is opened in order to form the polymer. Monomers having more than one double bond such as butadiene and isoprene yield polymers that contain double bonds (polybutadiene and polyisoprene) and are usually not considered polyolefins. Polyolefins are the foundations of many chemical industries.

Thermoplastic olefin, thermoplastic polyolefin (TPO), or olefinic thermoplastic elastomers refer to polymer/filler blends usually consisting of some fraction of a thermoplastic, an elastomer or rubber, and usually a filler.

Ethylene propylene rubber is a type of synthetic elastomer that is closely related to EPDM rubber. Since introduction in the 1960s, annual production has increased to 870,000 metric tons.

John E. Bercaw is an American chemist and Centennial Professor of Chemistry, Emeritus at the California Institute of Technology.

James Carl Stevens, a chemist, was the first Distinguished Fellow, at the Dow Chemical Company, retiring in January 2015. His area of expertise is organometallic chemistry and his primary field of research is in the area of polyolefin catalysis, particularly in the area of polyethylene, polypropylene, ethylene/styrene copolymers, and the combinatorial discovery of organometallic single-site catalysts. Stevens major contributions have come in the discovery and commercial implementation of single-site polyolefin catalysts. He invented and led the commercialization of constrained geometry catalyst for the polymerization of olefins. These have been commercialized by Dow as a number of polymers, elastomers and plostomers.

A plastomer is a polymer material which combines qualities of elastomers and plastics, such as rubber-like properties with the processing ability of plastic. As such, the word plastomer is a portmanteau of the words plastic and elastomer. Significant plastomers are ethylene-alpha olefin copolymers.

The Charles Goodyear Medal is the highest honor conferred by the American Chemical Society, Rubber Division. Established in 1941, the award is named after Charles Goodyear, the discoverer of vulcanization, and consists of a gold medal, a framed certificate and prize money. The medal honors individuals for "outstanding invention, innovation, or development which has resulted in a significant change or contribution to the nature of the rubber industry". Awardees give a lecture at an ACS Rubber Division meeting, and publish a review of their work in the society's scientific journal Rubber Chemistry and Technology.

The Melvin Mooney Distinguished Technology Award is a professional award conferred by the American Chemical Society, Rubber Division. Established in 1983, the award is named after Melvin Mooney, developer of the Mooney viscometer and of the Mooney-Rivlin hyperelastic law. The award consists of an engraved plaque and prize money. The medal honors individuals "who have exhibited exceptional technical competency by making significant and repeated contributions to rubber science and technology".

Rubber Chemistry and Technology is a quarterly peer-reviewed scientific journal covering fundamental research and technical developments relating to chemistry, materials science, and engineering of rubber, elastomers, and related materials. It was established in 1928, with Carroll C. Davis as its first editor-in-chief. The current editor-in-chief is Christopher G. Robertson. The journal is published by the American Chemical Society's Rubber Division. The journal currently publishes four issues per year containing original research contributions and review articles.

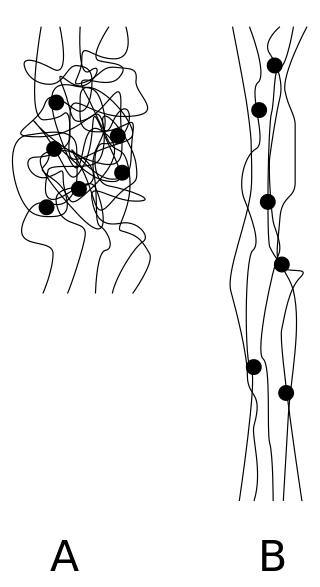

In polymer chemistry, graft polymers are segmented copolymers with a linear backbone of one composite and randomly distributed branches of another composite. The picture labeled "graft polymer" shows how grafted chains of species B are covalently bonded to polymer species A. Although the side chains are structurally distinct from the main chain, the individual grafted chains may be homopolymers or copolymers. Graft polymers have been synthesized for many decades and are especially used as impact resistant materials, thermoplastic elastomers, compatibilizers, or emulsifiers for the preparation of stable blends or alloys. One of the better-known examples of a graft polymer is a component used in high impact polystyrene, consisting of a polystyrene backbone with polybutadiene grafted chains.

Charles Michael Roland was Head of the Polymer Physics Section at the Naval Research Lab in Washington DC from 1989 to 2015. His research was concerned primarily with the dynamics of condensed matter, including polymers and liquid crystals, with applications to military armor and infrastructure protection. He is noted for his development of elastomeric coatings for blast protection, and for diverse accomplishments in the field of elastomer science. From 1991-1999, he served as the 8th editor of the scientific journal Rubber Chemistry and Technology, and a Fellow of the American Physical Society and the Institute of Materials, Minerals, and Mining (UK).

Francis Paul Baldwin was a former Exxon Chief Scientist noted for his work on chemical modifications of low functionality elastomers.

Sudhin Datta is an ExxonMobil Chemical scientist noted for the development of Vistamaxx propylene-based elastomers.

Albert M. Gessler was an ExxonMobil research chemist known for the development of elastomeric thermoplastics.

Maria D. Ellul is a retired ExxonMobil materials scientist known for her contributions to and development of commercial polyolefin and polyamide specialty thermoplastic elastomers, and recognized as one of the first prominent women scientists in the rubber industry.

Andy Haishung Tsou is a retired ExxonMobil materials scientist known for developing synchrotron X-ray scattering and atomic force microscopy techniques for polymer research, applying the techniques in service of development and commercialization of new polyolefin materials.

David John Lohse is a retired ExxonMobil materials scientist known for contributions on thermodynamics of mixing, nanocomposites for controlling permeability, neutron scattering of polymers, rheology of polymers.

References

- ↑ "Edward N Kresge". clustrmaps.com. Retrieved 23 September 2022.

- ↑ "Obituary of Edward Nathan Kresge". higginsfuneralhome.com. Higgins Funeral Home. Retrieved 1 November 2023.

- ↑ Noga, Ed (May 18, 2010). "Goodyear Medalist Kresge shares rich history". Rubber and Plastics News. Retrieved 4 Sep 2014.

- ↑ "Edward N. Kresge Charles Goodyear Medalist 2010". Rubber Chemistry and Technology. 83 (3): G2-G3. 2010. doi:10.5254/1.3525681.

- ↑ Kresge, Edward N. (September 2010). "Science and Serendipity in Polyolefin Elastomer Development". Rubber Chemistry and Technology. 83 (3): 227–234. doi:10.5254/1.3525682.

- ↑ Lohse, D. J.; Datta, S.; Kresge, E. N. (1991). "Graft copolymer compatibilizers for blends of polypropylene and ethylene-propylene copolymers". Macromolecules. 24 (2): 561–566. doi:10.1021/ma00002a034.