Related Research Articles

Structural engineering is a sub-discipline of civil engineering in which structural engineers are trained to design the 'bones and joints' that create the form and shape of human-made structures. Structural engineers also must understand and calculate the stability, strength, rigidity and earthquake-susceptibility of built structures for buildings and nonbuilding structures. The structural designs are integrated with those of other designers such as architects and building services engineer and often supervise the construction of projects by contractors on site. They can also be involved in the design of machinery, medical equipment, and vehicles where structural integrity affects functioning and safety. See glossary of structural engineering.

Structural analysis is a branch of solid mechanics which uses simplified models for solids like bars, beams and shells for engineering decision making. Its main objective is to determine the effect of loads on the physical structures and their components. In contrast to theory of elasticity, the models used in structure analysis are often differential equations in one spatial variable. Structures subject to this type of analysis include all that must withstand loads, such as buildings, bridges, aircraft and ships. Structural analysis uses ideas from applied mechanics, materials science and applied mathematics to compute a structure's deformations, internal forces, stresses, support reactions, velocity, accelerations, and stability. The results of the analysis are used to verify a structure's fitness for use, often precluding physical tests. Structural analysis is thus a key part of the engineering design of structures.

A beam is a structural element that primarily resists loads applied laterally across the beam's axis. Its mode of deflection is primarily by bending, as loads produce reaction forces at the beam's support points and internal bending moments, shear, stresses, strains, and deflections. Beams are characterized by their manner of support, profile, equilibrium conditions, length, and material.

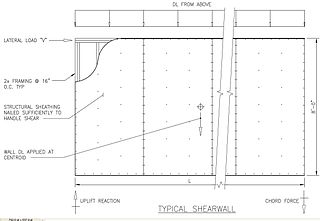

A shear wall is an element of a structurally engineered system that is designed to resist in-plane lateral forces, typically wind and seismic loads.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Seismic analysis is a subset of structural analysis and is the calculation of the response of a building structure to earthquakes. It is part of the process of structural design, earthquake engineering or structural assessment and retrofit in regions where earthquakes are prevalent.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible. Steel frame has displaced its predecessor, the iron frame, in the early 20th century.

Formwork is molds into which concrete or similar materials are either precast or cast-in-place. In the context of concrete construction, the falsework supports the shuttering molds. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure.

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes. Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel, bar stock, and rails. Most steel mills have rolling mill divisions that convert the semi-finished casting products into finished products.

Robert Maillart was a Swiss civil engineer who revolutionized the use of structural reinforced concrete with such designs as the three-hinged arch and the deck-stiffened arch for bridges, and the beamless floor slab and mushroom ceiling for industrial buildings. His Salginatobel (1929–1930) and Schwandbach (1933) bridges changed the aesthetics and engineering of bridge construction dramatically and influenced decades of architects and engineers after him. In 1991 the Salginatobel Bridge was declared an International Historic Civil Engineering Landmark by the American Society of Civil Engineers.

This is an alphabetical list of articles pertaining specifically to structural engineering. For a broad overview of engineering, please see List of engineering topics. For biographies please see List of engineers.

Structural mechanics or mechanics of structures is the computation of deformations, deflections, and internal forces or stresses within structures, either for design or for performance evaluation of existing structures. It is one subset of structural analysis. Structural mechanics analysis needs input data such as structural loads, the structure's geometric representation and support conditions, and the materials' properties. Output quantities may include support reactions, stresses and displacements. Advanced structural mechanics may include the effects of stability and non-linear behaviors.

A steel plate shear wall (SPSW) consists of steel infill plates bounded by boundary elements.

The history of structural engineering dates back to at least 2700 BC when the step pyramid for Pharaoh Djoser was built by Imhotep, the first architect in history known by name. Pyramids were the most common major structures built by ancient civilizations because it is a structural form which is inherently stable and can be almost infinitely scaled.

Cold-formed steel (CFS) is the common term for steel products shaped by cold-working processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of cold-rolled steel (CRS) are commonly used in all areas of manufacturing. The terms are opposed to hot-formed steel and hot-rolled steel.

In structural engineering, a pre-engineered building (PEB) is designed by a PEB supplier or PEB manufacturer with a single design to be fabricated using various materials and methods to satisfy a wide range of structural and aesthetic design requirements. This is contrasted with a building built to a design that was created specifically for that building. Within some geographic industry sectors pre-engineered buildings are also called pre-engineered metal buildings (PEMB) or, as is becoming increasingly common due to the reduced amount of pre-engineering involved in custom computer-aided designs, simply engineered metal buildings (EMB).

In the Eurocode series of European standards (EN) related to construction, Eurocode 3: Design of steel structures describes how to design steel structures, using the limit state design philosophy.

Flexcom is a finite element analysis software package used in the offshore oil and gas and marine renewable energy industries. An educational version is also available for universities.

In structural engineering and mechanical engineering, generalised beam theory (GBT) is a one-dimensional theory used to mathematically model how beams bend and twist under various loads. It is a generalization of classical Euler–Bernoulli beam theory that approximates a beam as an assembly of thin-walled plates that are constrained to deform as a linear combination of specified deformation modes.

Konstantinos Daniel Tsavdaridis is a professor at the School of Civil Engineering of the University of Leeds, known for his work on lightweight steel and steel-concrete composite structures and particularly for the design of novel perforated beams and tall buildings.

References

- Cheung, Y.K. “Finite strip method in structural analysis”, Pergamon Press, 1976.

- "Developments in Tall Buildings 1983". ISBN 0-87933-048-1. Pages 571 - 572.

- Cheung, Y.K. and Tham, L.G. “Finite strip method”, CRC Press, 1998.

- Schafer, B.W., Ádány, S. “Buckling analysis of cold-formed steel members using CUFSM: conventional and constrained finite strip methods.” Eighteenth International Specialty Conference on Cold-Formed Steel Structures, Orlando, FL. October 2006. (pdf)