A thermoplastic, or thermosofteningplastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end use. Packaging contains, protects, preserves, transports, informs, and sells. In many countries it is fully integrated into government, business, institutional, industrial, and for personal use.

A drum is a cylindrical shipping container used for shipping bulk cargo. Drums can be made of steel, dense paperboard, or plastic, and are generally used for the transportation and storage of liquids and powders. Drums are often stackable, and have dimensions designed for efficient warehouse and logistics use. This type of packaging is frequently certified for transporting dangerous goods. Proper shipment requires the drum to comply with all applicable regulations.

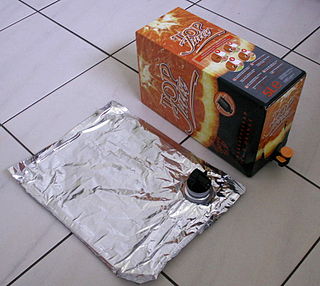

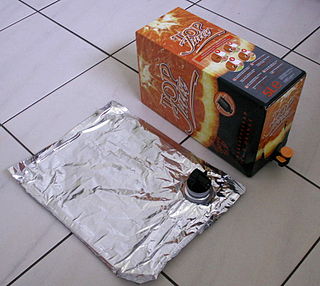

A bag-in-box or BiB is a container for the storage and transportation of liquids. It consists of a strong bladder, usually made of several layers of metallised film or other plastics, seated inside a corrugated fiberboard box.

A fuel tank is a safe container for flammable fluids, often gasoline or diesel fuel. Though any storage tank for fuel may be so called, the term is typically applied to part of an engine system in which the fuel is stored and propelled or released into an engine. Fuel tanks range in size and complexity from the small plastic tank of a butane lighter to the multi-chambered cryogenic Space Shuttle external tank.

A plastic bag, poly bag, or pouch is a type of container made of thin, flexible, plastic film, nonwoven fabric, or plastic textile. Plastic bags are used for containing and transporting goods such as foods, produce, powders, ice, magazines, chemicals, and waste. It is a common form of packaging.

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code.

Cardboard boxes are industrially prefabricated boxes, primarily used for packaging goods and materials. Specialists in industry seldom use the term cardboard because it does not denote a specific material. The term cardboard may refer to a variety of heavy paper-like materials, including card stock, corrugated fiberboard, and paperboard. Cardboard boxes can be readily recycled.

Intermediate bulk containers are industrial-grade containers engineered for the mass handling, transport, and storage of liquids, semi-solids, pastes, or granular solids. There are several types of IBCs with the two main categories being flexible IBCs and rigid IBCs. Many IBCs are reused with proper cleaning and reconditioning or repurposed.

Ground support equipment (GSE) is the support equipment found at an airport, usually on the apron, the servicing area by the terminal. This equipment is used to service the aircraft between flights. As the name suggests, ground support equipment is there to support the operations of aircraft whilst on the ground. The role of this equipment generally involves ground power operations, aircraft mobility, and cargo/passenger loading operations.

Tank blanketing, also called gas sealing or tank padding, is the process of applying a gas to the empty space in a storage container. The term storage container here refers to any container that is used to store products, regardless of its size. Though tank blanketing is used for a variety of reasons, it typically involves using a buffer gas to protect products inside the storage container. A few of the benefits of blanketing include a longer product life in the container, reduced hazards, and longer equipment life cycles.

A flexible intermediate bulk container (FIBC), jumbo, bulk bag, super sack, big bag, or tonne bag is an industrial container made of flexible fabric that is designed for storing and transporting dry, flowable products, such as sand, fertilizer, and granules of plastic.

A plastic bottle is a bottle constructed from high-density or low density plastic. Plastic bottles are typically used to store liquids such as water, soft drinks, motor oil, cooking oil, medicine, shampoo or milk. They range in sizes, from very small bottles to large carboys. Consumer blow molded containers often have integral handles or are shaped to facilitate grasping.

Aseptic processing is a processing technique wherein commercially thermally sterilized liquid products are packaged into previously sterilized containers under sterile conditions to produce shelf-stable products that do not need refrigeration. Aseptic processing has almost completely replaced in-container sterilization of liquid foods, including milk, fruit juices and concentrates, cream, yogurt, salad dressing, liquid egg, and ice cream mix. There has been an increasing popularity for foods that contain small discrete particles, such as cottage cheese, baby foods, tomato products, fruit and vegetables, soups, and rice desserts.

A tank container or tanktainer is an intermodal container for the transport of liquids, gases and powders as bulk cargo. It is built to the ISO standards, making it suitable for different modes of transportation; as such, it is also called an ISO tank. Both hazardous and non-hazardous products can be transported in tank containers.

International Classification of Goods and Services also known as the Nice Classification was established by the Nice Agreement (1957), is a system of classifying goods and services for the purpose of registering trademarks. It is updated every five years and its latest 11th version of the system groups products into 45 classes, and allows users seeking to trademark a good or service to choose from these classes as appropriate. Since the system is recognized in numerous countries, this makes applying for trademarks internationally a more streamlined process. The classification system is specified by the World Intellectual Property Organization (WIPO).

A shipping container is a container with strength suitable to withstand shipment, storage, and handling. Shipping containers range from large reusable steel boxes used for intermodal shipments to the ubiquitous corrugated boxes. In the context of international shipping trade, "container" or "shipping container" is virtually synonymous with "intermodal freight container", a container designed to be moved from one mode of transport to another without unloading and reloading.

Pumpable icetechnology (PIT) uses thin liquids, with the cooling capacity of ice. Pumpable ice is typically a slurry of ice crystals or particles ranging from 5 micrometers to 1 cm in diameter and transported in brine, seawater, food liquid, or gas bubbles of air, ozone, or carbon dioxide.

Fuel bladders, fuel storage bladders are a type of Flexi-bag used as a fuel container. They are collapsible, flexible storage bladders that provide transport and storage for bulk industrial liquids such as fuels.

A bladder tank is a large, flexible container used to store many types of liquids. When maximum capacity is reached, the bladder tank takes the form of a large pillow, hence it is also called a pillow tank.