A nuclear reactor, formerly known as an atomic pile, is a device used to initiate and control a self-sustained nuclear chain reaction. Nuclear reactors are used at nuclear power plants for electricity generation and in nuclear marine propulsion. Heat from nuclear fission is passed to a working fluid, which in turn runs through steam turbines. These either drive a ship's propellers or turn electrical generators' shafts. Nuclear generated steam in principle can be used for industrial process heat or for district heating. Some reactors are used to produce isotopes for medical and industrial use, or for production of weapons-grade plutonium. As of early 2019, the IAEA reports there are 454 nuclear power reactors and 226 nuclear research reactors in operation around the world.

A pressurized water reactor (PWR) is a type of light-water nuclear reactor. PWRs constitute the large majority of the world's nuclear power plants. In a PWR, the primary coolant (water) is pumped under high pressure to the reactor core where it is heated by the energy released by the fission of atoms. The heated, high pressure water then flows to a steam generator, where it transfers its thermal energy to lower pressure water of a secondary system where steam is generated. The steam then drives turbines, which spin an electric generator. In contrast to a boiling water reactor (BWR), pressure in the primary coolant loop prevents the water from boiling within the reactor. All light-water reactors use ordinary water as both coolant and neutron moderator. Most use anywhere from 2 to 4 vertically mounted steam generators; VVER reactors use horizontal steam generators.

A boiling water reactor (BWR) is a type of light water nuclear reactor used for the generation of electrical power. It is the second most common type of electricity-generating nuclear reactor after the pressurized water reactor (PWR), which is also a type of light water nuclear reactor. The main difference between a BWR and PWR is that in a BWR, the reactor core heats water, which turns to steam and then drives a steam turbine. In a PWR, the reactor core heats water, which does not boil. This hot water then exchanges heat with a lower pressure water system, which turns to steam and drives the turbine. The BWR was developed by the Argonne National Laboratory and General Electric (GE) in the mid-1950s. The main present manufacturer is GE Hitachi Nuclear Energy, which specializes in the design and construction of this type of reactor.

A nuclear meltdown is a severe nuclear reactor accident that results in core damage from overheating. The term nuclear meltdown is not officially defined by the International Atomic Energy Agency or by the Nuclear Regulatory Commission. It has been defined to mean the accidental melting of the core of a nuclear reactor, however, and is in common usage a reference to the core's either complete or partial collapse.

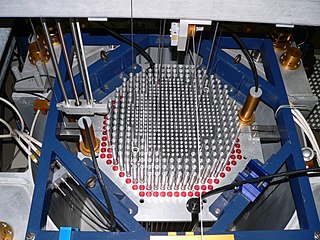

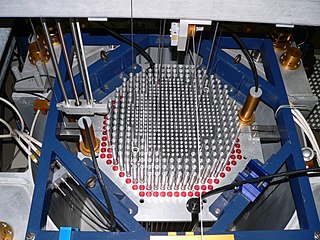

The RBMK is a class of graphite-moderated nuclear power reactor designed and built by the Soviet Union. The name refers to its unusual design where, instead of a large steel pressure vessel surrounding the entire core, each fuel assembly is enclosed in an individual 8 cm diameter pipe which allows the flow of cooling water around the fuel.

A loss-of-coolant accident (LOCA) is a mode of failure for a nuclear reactor; if not managed effectively, the results of a LOCA could result in reactor core damage. Each nuclear plant's emergency core cooling system (ECCS) exists specifically to deal with a LOCA.

The light-water reactor (LWR) is a type of thermal-neutron reactor that uses normal water, as opposed to heavy water, as both its coolant and neutron moderator – furthermore a solid form of fissile elements is used as fuel. Thermal-neutron reactors are the most common type of nuclear reactor, and light-water reactors are the most common type of thermal-neutron reactor.

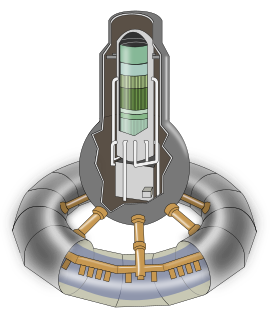

Passive nuclear safety is a design approach for safety features, implemented in a nuclear reactor, that does not require any active intervention on the part of the operator or electrical/electronic feedback in order to bring the reactor to a safe shutdown state, in the event of a particular type of emergency. Such design features tend to rely on the engineering of components such that their predicted behaviour would slow down, rather than accelerate the deterioration of the reactor state; they typically take advantage of natural forces or phenomena such as gravity, buoyancy, pressure differences, conduction or natural heat convection to accomplish safety functions without requiring an active power source. Many older common reactor designs use passive safety systems to a limited extent, rather, relying on active safety systems such as diesel powered motors. Some newer reactor designs feature more passive systems; the motivation being that they are highly reliable and reduce the cost associated with the installation and maintenance of systems that would otherwise require multiple trains of equipment and redundant safety class power supplies in order the achieve the same level of reliability. However, weak driving forces that power many passive safety features can pose significant challenges to effectiveness of a passive system, particularly in the short term following an accident.

A steam explosion is an explosion caused by violent boiling or flashing of water into steam, occurring when water is either superheated, rapidly heated by fine hot debris produced within it, or heated by the interaction of molten metals. Pressure vessels, such as pressurized water (nuclear) reactors, that operate above atmospheric pressure can also provide the conditions for a steam explosion. The water changes from a liquid to a gas with extreme speed, increasing dramatically in volume. A steam explosion sprays steam and boiling-hot water and the hot medium that heated it in all directions, creating a danger of scalding and burning.

A containment building, in its most common usage, is a reinforced steel or lead structure enclosing a nuclear reactor. It is designed, in any emergency, to contain the escape of radioactive steam or gas to a maximum pressure in the range of 275 to 550 kPa. The containment is the fourth and final barrier to radioactive release, the first being the fuel ceramic itself, the second being the metal fuel cladding tubes, the third being the reactor vessel and coolant system.

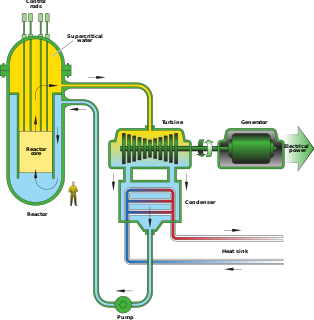

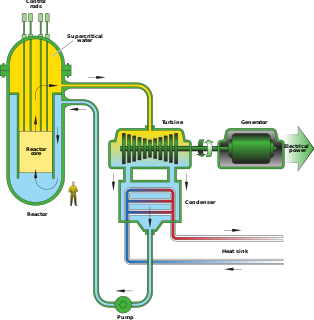

The supercritical water reactor (SCWR) is a concept Generation IV reactor, mostly designed as light water reactor (LWR) that operates at supercritical pressure. The term critical in this context refers to the critical point of water, and must not be confused with the concept of criticality of the nuclear reactor.

Steam generators are heat exchangers used to convert water into steam from heat produced in a nuclear reactor core. They are used in pressurized water reactors (PWR) between the primary and secondary coolant loops.

A liquid metal cooled nuclear reactor, liquid metal fast reactor or LMFR is an advanced type of nuclear reactor where the primary coolant is a liquid metal. Liquid metal cooled reactors were first adapted for nuclear submarine use but have also been extensively studied for power generation applications.

The three primary objectives of nuclear reactor safety systems as defined by the U.S. Nuclear Regulatory Commission are to shut down the reactor, maintain it in a shutdown condition and prevent the release of radioactive material.

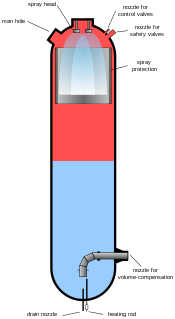

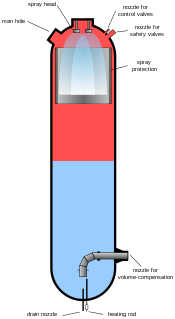

A pressurizer is a component of a pressurized water reactor. The basic design of the pressurized water reactor includes a requirement that the coolant (water) in the reactor coolant system must not boil. Put another way, the coolant must remain in the liquid state at all times, especially in the reactor vessel. To achieve this, the coolant in the reactor coolant system is maintained at a pressure sufficiently high that boiling does not occur at the coolant temperatures experienced while the plant is operating or in any analyzed possible transient state. To pressurize the coolant system to a higher pressure than the vapor pressure of the coolant at operating temperatures, a separate pressurizing system is required. This is in the form of the pressurizer.

A nuclear reactor coolant is a coolant in a nuclear reactor used to remove heat from the nuclear reactor core and transfer it to electrical generators and the environment. Frequently, a chain of two coolant loops are used because the primary coolant loop takes on short-term radioactivity from the reactor.

Boiling water reactor safety systems are nuclear safety systems constructed within boiling water reactors in order to prevent or mitigate environmental and health hazards in the event of accident or natural disaster.

General Electric's BWR product line of Boiling Water Reactors represents the designs of a relatively large percentage of the commercial fission reactors around the world.

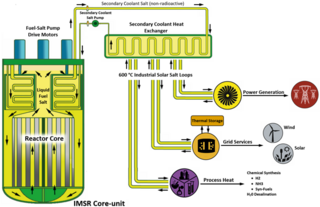

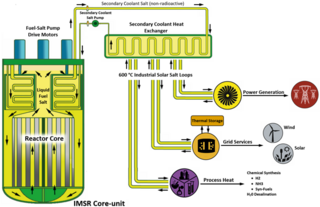

The Integral Molten Salt Reactor (IMSR) is designed for the small modular reactor (SMR) market. It employs molten salt reactor technology which is being developed by the Canadian company Terrestrial Energy. It is based closely on the denatured molten salt reactor (DMSR), a reactor design from Oak Ridge National Laboratory. It also incorporates elements found in the SmAHTR, a later design from the same laboratory. The IMSR belongs to the DMSR class of molten salt reactors (MSR) and hence is a "burner" reactor that employs a liquid fuel rather than a conventional solid fuel; this liquid contains the nuclear fuel and also serves as primary coolant.

The removal of heat from nuclear reactors is an essential step in the generation of energy from nuclear reactions. In nuclear engineering there are a number of empirical or semi-empirical relations used for quantifying the process of removing heat from a nuclear reactor core so that the reactor operates in the projected temperature interval that depends on the materials used in the construction of the reactor. The effectiveness of removal of heat from the reactor core depends on many factors, including the cooling agents used and the type of reactor. Common coolers for nuclear reactors include: heavy water, the first alkaline metals, lead or lead-based alloys, and .