Glass fiber is a material consisting of numerous extremely fine fibers of glass.

Fiberglass or fibreglass is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic.

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure or mixing with a catalyst. Heat is not necessarily applied externally, and is often generated by the reaction of the resin with a curing agent. Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network.

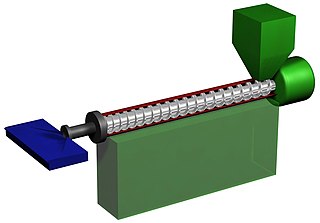

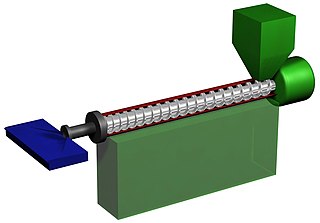

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process.

Fibre-reinforced plastic is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass, carbon, aramid, or basalt. Rarely, other fibres such as paper, wood, boron, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use.

A mandrel, mandril, or arbor is a tapered tool against which material can be forged, pressed, stretched or shaped, or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an opposing thread is screwed onto the mandrel.

Glass tubes are mainly cylindrical hollow-wares. Their special shape combined with the huge variety of glass types, allows the use of glass tubing in many applications. For example, laboratory glassware, lighting applications, solar thermal systems and pharmaceutical packaging to name the largest.

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures. This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates around the spindle while a delivery eye on a carriage traverses horizontally in line with the axis of the rotating mandrel, laying down fibers in the desired pattern or angle to the rotational axis. The most common filaments are glass or carbon and are impregnated with resin by passing through a bath as they are wound onto the mandrel. Once the mandrel is completely covered to the desired thickness, the resin is cured. Depending on the resin system and its cure characteristics, often the mandrel is autoclaved or heated in an oven or rotated under radiant heaters until the part is cured. Once the resin has cured, the mandrel is removed or extracted, leaving the hollow final product. For some products such as gas bottles, the 'mandrel' is a permanent part of the finished product forming a liner to prevent gas leakage or as a barrier to protect the composite from the fluid to be stored.

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

A expansion joint, or movement joint, is an assembly designed to hold parts together while safely absorbing temperature-induced expansion and contraction of building materials. They are commonly found between sections of buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

Composite gear housing refers to the use of composite materials to enclose the components of motor transmissions. Fiber reinforced composite materials are used primarily for weight reduction. Carbon fiber reinforced plastic material is commonly used in the aerospace and automotive industries.

SoluForce is a type of Reinforced Thermoplastic Pipe.

Reinforced thermoplastic pipe (RTP) is a type of pipe reinforced using a high strength synthetic fibre such as glass, aramid or carbon. It was initially developed in the early 1990s by Wavin Repox, Akzo Nobel and by Tubes d'Aquitaine from France, who developed the first pipes reinforced with synthetic fibre to replace medium pressure steel pipes in response to growing demand for non-corrosive conduits for application in the onshore oil and gas industry, particularly in the Middle East. Typically, the materials used in the construction of the pipe might be Polyethylene (PE), Polyamide-11 or PVDF and may be reinforced with Aramid or Polyester fibre although other combinations are used. More recently the technology of producing such pipe, including the marketing, rests with a few key companies, where it is available in coils up to 400 m (1,312 ft) length. These pipes are available in pressure ratings from 30 to 90 bar. Over the last few years this type of pipe has been acknowledged as a standard alternative solution to steel for oilfield flowline applications by certain oil companies and operators. An advantage of this pipe is also its very fast installation time compared to steel pipe when considering the welding time as average speeds up to 1,000 m (3,281 ft)/day have been reached installing RTP in ground surface.

Jotun is a Norwegian multinational chemicals company dealing mainly in decorative paints and performance coatings. It is one of the world's largest manufacturers of paints and coating products. Jotun manufactures paints and varnishes for marine and industrial purposes, synthetic resins, floor coverings, polyurethane foam, heavy-duty coatings, binders, unsaturated polyesters, glass-fiber reinforced polyester pipes, tanks, and more.

FRP is a modern composite material of construction for chemical plant, pulp and paper mill, and food and pharmaceutical equipment like tanks and vessels. Chemical equipment that range in size from less than a metre to 20 metres are fabricated using FRP as material of construction.

Carbon fiber-reinforced polymers, carbon-fibre-reinforced polymers, carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic, also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications.

Fiberglass reinforced plastic grating is a composite material manufactured by combining a matrix of resin and fiberglass. Fiberglass grating does not corrode like steel grating and is therefore used in corrosive environments to reduce maintenance costs. It is used in a variety of applications including walkways and overhead platforms. FRP grating is a structural product that can be weight-bearing between spans.

A continuous filament winding machine is a machine for laying filament windings continuously over a cylindrical steel band. The steel band is carried on a forward moving mandrel which is able to collapse and return to the beginning of the travel. The steel band is released after the mandrel collapses and is continuously fed back to the start of the travel where it is again wound on to the mandrel.

A discontinuous filament winding machine is a machine for laying fiberglass filament windings over a cylindrical mould or mandrel bar using a carriage that is traveling along the axis of that mandrel. The mandrel is fixed on a mandrel stand and is rotated by an asynchronous motor. The carriage is the set-up that holds and winds the fiberglass on the rotating mandrel. The difference between the continuous and discontinuous filament winding machine is the area on which filament winding is laying out.

Covema srl was a historic Italian company specializing in the design of plastic processing machinery, based in Milan, via Fontana 1. Founded in 1953 by the Terragni brothers, it also included the companies Corima spa, GBF spa, GBF iberica, RIAP srl, FIRS spa, Covepla Spain, Italproducts srl, Omam spa, TPA srl, AGRIPAK srl, Floraplant srl, Interfinance SA, Technical Die spa, Covema SAE. The technology that Covema has developed since the 1950s is merged into Agripak srl based in Milano and managed by the sons of Marco Terragni: Fabio Terragni (president), Patrizia Terragni and Massimo Terragni.